Information injection-pump assembly

BOSCH

9 400 616 231

9400616231

ZEXEL

101893-1050

1018931050

MITSUBISHI

ME066782

me066782

Rating:

Service parts 101893-1050 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

31161-18000

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 616 231

9400616231

ZEXEL

101893-1050

1018931050

MITSUBISHI

ME066782

me066782

Zexel num

Bosch num

Firm num

Name

101893-1050

9 400 616 231

ME066782 MITSUBISHI

INJECTION-PUMP ASSEMBLY

8DC6 * K

8DC6 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

2.1

2.05

2.15

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

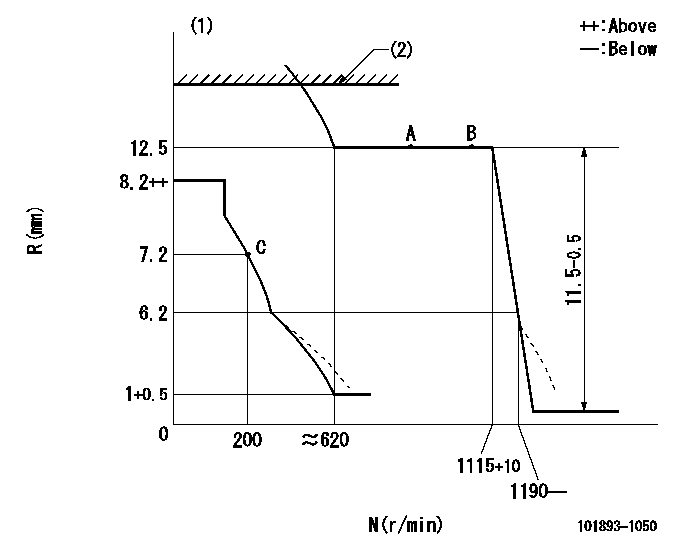

Injection quantity adjustment

Adjusting point

A

Rack position

12.5

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

129.5

125.6

133.4

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

12.5

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

131

127.5

134.5

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.2+-0.5

Pump speed

r/min

200

200

200

Average injection quantity

mm3/st.

15

12

18

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

250+120

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

2

1.5

2.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

5.2

4.7

5.7

Timer adjustment_04

Pump speed

r/min

1200

Advance angle

deg.

8

7.5

8.5

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

10

10

10

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Damper spring setting: DL

(2)RACK LIMIT: RAL

----------

DL=4.5-0.5mm RAL=12.5+0.2mm

----------

----------

DL=4.5-0.5mm RAL=12.5+0.2mm

----------

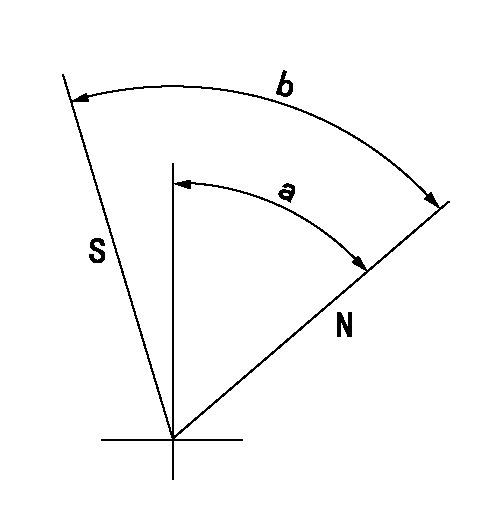

Speed control lever angle

F:Full speed

----------

----------

a=9deg+-5deg

----------

----------

a=9deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=11deg+-5deg b=41deg+-3deg

----------

----------

a=11deg+-5deg b=41deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=54deg+-5deg b=75deg+-5deg

----------

----------

a=54deg+-5deg b=75deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325+10r/min Ra=7.2mm

----------

----------

N1=325+10r/min Ra=7.2mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Illustration 5 g06198951

70-Pin connector

(5) Pin 4

(6) Pin 24

Illustration 6 g06198953

40-Pin connector

(7) Pin 4

(8) Pin 24

Using the appropriate terminal extraction tool, remove the red and black wires from positions 4 and 24 of the connector. Refer to Illustration 5 and 6.

Route the extracted wires out of the engine harness and insert the wires into 3E-3370 Connector Receptacle As supplied with 517-0586 Engine Harness As. Red wire in position 1 and Black wire in position 2.Note: Minor cutting of the boot may be required.

Install the Red wire from 517-0586 Engine Harness As into position 4 of the Machine Interface Connector and install the Black wire into position 24 of the connector.

Illustration 7 g06237613

70 Pin Harness

(A) Pin 4 From Machine Interface Harness Connector

(B) Pin 24 From Machine Interface Harness Connector

(C) Pyrometer Harness Interface Connector

(D) Machine Interface Connector

Illustration 8 g06237606

40 Pin Harness

(A) Pin 4 From Machine Interface Harness Connector

(B) Pin 24 From Machine Interface Harness Connector

(E) Flying Power Leads from 514-3813 Harness As to 2 Pin Connector

(F) Machine Interface Connector

If the Pyrometer Interface Harness connector is a 70 pin, Route 517-0586 Engine Harness As to the Pyrometer Harness Interface connector and install Red wire into position 70 and the Black wire into position 69. If the Pyrometer Interface Harness connector is a 40 pin, install the Red wire into pin 1 of a 2-pin receptacle and the Black wire into pin 2. This connector will then connect to G-C3 of 514-3813 Engine Harness As.

With the engine powered, use a digital multimeter to verify that 24V power is present at the Pyrometer Harness Interface connector.Installation of 510-4068 Electronic Control Gp (Pyrometer)

Attach 489-3081 Harness As to 510-4068 Electronic Control Gp (Pyrometer) and the Pyrometer Interface Connector. Using 489-3081 Engine Harness As as a gauge, temporarily install the module on an appropriate place as per the choice of installer.Installation of 505-1731 Engine Harness As

If the engine under test is a 16 cylinder instead of a 20 cylinder, 505-1731 Engine Harness As can be installed between 489-3081 Engine Harness As and 510-4068 Electronic Control Gp.Installation of 489-3081 Engine Harness As

Perform the following procedure to install 489-3081 Engine Harness As:

Install 504-3341 Engine Harness As on the service port connector of 489-3081 Engine Harness As.

Route 504-3341 Engine Harness As to a safe location before performing tests.Note: Attach 140-9442 "Y" Adapter Cable As in order to see all the machine ECMs. Connect 504-3341 Monitor Harness As to "Y", connect other leg to Machine Service port and the third leg to Communication Adapter.Overview and Configuration On Caterpillar Electronic Technician (Cat ET)

This section will describe the overview and configuration setting on Cat ET.Cat ET Screen - Standard View

Perform the following instructions once the system is installed:

Connect to communications adapter and launch Cat ET.

Illustration 9 g06198935

After connecting, under "Available ECM(s)" select "Digital Pyrometer #1".

Illustration 10 g06199349

(9) Status button

Select the "Status" (9) button in the toolbar and then the parameters of "Digital Pyrometer #1" will appear.

Selecting "Engine Cylinder Temperature - 1"

Have questions with 101893-1050?

Group cross 101893-1050 ZEXEL

Mitsubishi

101893-1050

9 400 616 231

ME066782

INJECTION-PUMP ASSEMBLY

8DC6

8DC6