Information injection-pump assembly

BOSCH

9 400 616 221

9400616221

ZEXEL

101891-6550

1018916550

MITSUBISHI

3126185091

3126185091

Rating:

Include in #1:

101602-1212

as _

Cross reference number

BOSCH

9 400 616 221

9400616221

ZEXEL

101891-6550

1018916550

MITSUBISHI

3126185091

3126185091

Zexel num

Bosch num

Firm num

Name

101891-6550

9 400 616 221

3126185091 MITSUBISHI

INJECTION-PUMP ASSEMBLY

8DC60 * K

8DC60 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

2.1

2.05

2.15

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

12.5

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

128.8

124.9

132.7

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

12

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

123

118

128

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

11.3

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

108.2

103.7

112.7

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

7.2+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

17.5

14.5

20.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

250+120

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

2

1.5

2.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

5.2

4.7

5.7

Timer adjustment_04

Pump speed

r/min

1200

Advance angle

deg.

8

7.5

8.5

Remarks

Finish

Finish

Test data Ex:

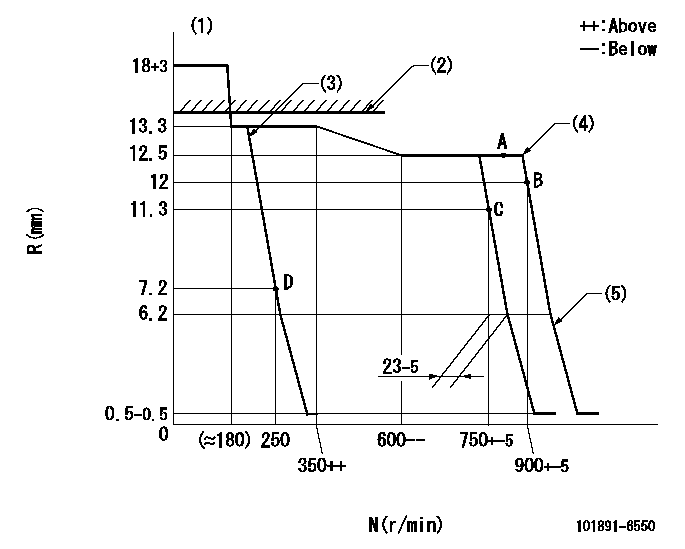

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)Control lever's minimum speed setting

(4)Control lever's full speed setting

(5)Idle sub spring setting: L1.

----------

K=5 RAL=13.3+0.5mm L1=6.2-0.2mm

----------

----------

K=5 RAL=13.3+0.5mm L1=6.2-0.2mm

----------

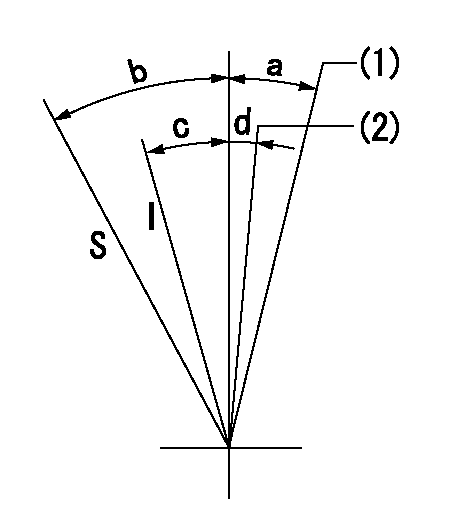

Speed control lever angle

I:Idle

S:Stop

(1)Set the pump speed at aa

(2)Set the pump speed at bb.

----------

aa=900r/min bb=750r/min

----------

a=(13deg) b=32deg+-3deg c=(22deg) d=(5deg)

----------

aa=900r/min bb=750r/min

----------

a=(13deg) b=32deg+-3deg c=(22deg) d=(5deg)

Information:

This Special Instruction details the Diesel Particulate Filter (DPF) maintenance on C2.4, C3.3B, and C3.8 machine engines.Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.Reference

Reference: Special Instructions , REHS7788, "Cleaning the Diesel Particulate Filter (DPF) on C2.4, C3.3B, and C3.8 Engines."Reference: Troubleshooting , "Diesel Particulate Filter Active Regeneration Occurrence is Excessive".Reference: Troubleshooting , "Oil Contains Fuel".Reference: Disassembly and Assembly , "Diesel Particulate Filter- Remove and Install".Safety

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Failure to follow all safety guidelines prescribed in this document and by governing authorities and regulatory agencies may result in severe injury or death of personnel or machine damage.

When removing a major component or attachment, ensure that it is properly blocked or secured before removing mounting hardware. An assembly that is disconnected without proper blocking may shift or fall, resulting in serious injury or death of personnel or machine damage.

Personal injury or death can result from improper maintenance procedures. To avoid injury or death, follow the procedures exactly as stated below.

Personal injury can result from improper handling of chemicals.Make sure you use all the necessary protective equipment required to do the job.Make sure that you read and understand all directions and hazards described on the labels and material safety data sheet of any chemical that is used.Observe all safety precautions recommended by the chemical manufacturer for handling, storage, and disposal of chemicals.

Maintenance Procedure

There are three options for servicing the Diesel Particulate Filter (DPF).

Diesel Particulate Filter (DPF) can be cleaned by the Cat® dealer.

Replaced with a certified clean Diesel Particulate Filter (DPF) from Cat® Reman.

New Diesel Particulate Filter (DPF) installed.Note: The lowest cost option is the Diesel Particulate Filter (DPF) is cleaned by the Cat® dealer.

Refer to Special Instructions , REHS7788 for cleaning procedures.This document has the acceptable reuse guidelines such as max number of cracked or missing end caps and minimum remaining ash pin depth as measured by a pin gauge.Note: The C3.8 tier 4 final (EU stage 3B) currently does not have a certified clean Diesel Particulate Filter (DPF) available from Cat® Reman.

DPF cleaning is recommended to do at 3000 hrs as part of preventive maintenance, which ensures planned downtime. If the dealer and customer choose to not do this pro-actively at 3000 hrs, then Caterpillar is not responsible for any subsequent damage to the engine or emission components as a result.

If preventive maintenance is not done pro-actively, one of the following will occur which may indicate the Diesel Particulate Filter (DPF) is full or near full:

523602-0 High Frequency Regeneration code occurs.

Fuel Dilution is flagged in the SOS oil sample.

523602-0 High Frequency Regeneration indicated that active regenerations (in-cylinder dosing) occurred within 30 minutes of the prior and this occurred three times in a

Reference: Special Instructions , REHS7788, "Cleaning the Diesel Particulate Filter (DPF) on C2.4, C3.3B, and C3.8 Engines."Reference: Troubleshooting , "Diesel Particulate Filter Active Regeneration Occurrence is Excessive".Reference: Troubleshooting , "Oil Contains Fuel".Reference: Disassembly and Assembly , "Diesel Particulate Filter- Remove and Install".Safety

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Failure to follow all safety guidelines prescribed in this document and by governing authorities and regulatory agencies may result in severe injury or death of personnel or machine damage.

When removing a major component or attachment, ensure that it is properly blocked or secured before removing mounting hardware. An assembly that is disconnected without proper blocking may shift or fall, resulting in serious injury or death of personnel or machine damage.

Personal injury or death can result from improper maintenance procedures. To avoid injury or death, follow the procedures exactly as stated below.

Personal injury can result from improper handling of chemicals.Make sure you use all the necessary protective equipment required to do the job.Make sure that you read and understand all directions and hazards described on the labels and material safety data sheet of any chemical that is used.Observe all safety precautions recommended by the chemical manufacturer for handling, storage, and disposal of chemicals.

Maintenance Procedure

There are three options for servicing the Diesel Particulate Filter (DPF).

Diesel Particulate Filter (DPF) can be cleaned by the Cat® dealer.

Replaced with a certified clean Diesel Particulate Filter (DPF) from Cat® Reman.

New Diesel Particulate Filter (DPF) installed.Note: The lowest cost option is the Diesel Particulate Filter (DPF) is cleaned by the Cat® dealer.

Refer to Special Instructions , REHS7788 for cleaning procedures.This document has the acceptable reuse guidelines such as max number of cracked or missing end caps and minimum remaining ash pin depth as measured by a pin gauge.Note: The C3.8 tier 4 final (EU stage 3B) currently does not have a certified clean Diesel Particulate Filter (DPF) available from Cat® Reman.

DPF cleaning is recommended to do at 3000 hrs as part of preventive maintenance, which ensures planned downtime. If the dealer and customer choose to not do this pro-actively at 3000 hrs, then Caterpillar is not responsible for any subsequent damage to the engine or emission components as a result.

If preventive maintenance is not done pro-actively, one of the following will occur which may indicate the Diesel Particulate Filter (DPF) is full or near full:

523602-0 High Frequency Regeneration code occurs.

Fuel Dilution is flagged in the SOS oil sample.

523602-0 High Frequency Regeneration indicated that active regenerations (in-cylinder dosing) occurred within 30 minutes of the prior and this occurred three times in a

Have questions with 101891-6550?

Group cross 101891-6550 ZEXEL

Mitsubishi

101891-6550

9 400 616 221

3126185091

INJECTION-PUMP ASSEMBLY

8DC60

8DC60