Information injection-pump assembly

BOSCH

9 400 616 220

9400616220

ZEXEL

101891-6510

1018916510

MITSUBISHI

3126185021

3126185021

Rating:

Service parts 101891-6510 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

31161-18000

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 616 220

9400616220

ZEXEL

101891-6510

1018916510

MITSUBISHI

3126185021

3126185021

Zexel num

Bosch num

Firm num

Name

101891-6510

9 400 616 220

3126185021 MITSUBISHI

INJECTION-PUMP ASSEMBLY

8DC20 K 14BG INJECTION PUMP ASSY PE8A PE

8DC20 K 14BG INJECTION PUMP ASSY PE8A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

2.2

2.15

2.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

14

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

138

133.9

142.1

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

12.3

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

121.8

117

126.6

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

5.5+-0.5

Pump speed

r/min

200

200

200

Average injection quantity

mm3/st.

12.4

9.8

15

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

250+120

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

1.4

0.8

2

Timer adjustment_03

Pump speed

r/min

800

Advance angle

deg.

4.2

3.6

4.8

Timer adjustment_04

Pump speed

r/min

1200

Advance angle

deg.

8

7.3

8.5

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

10

10

10

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

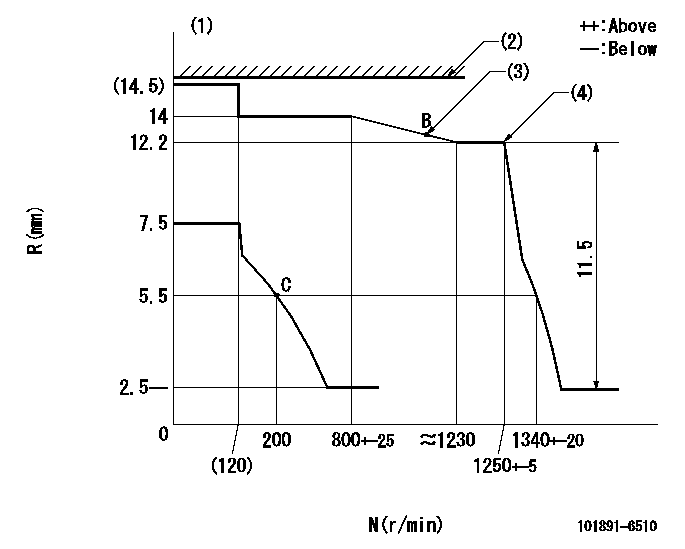

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)Set the torque control spring so that the injection quantity passes through point B.

(4)Torque spring does not operate.

----------

K=8 RAL=14.5+0.5mm

----------

----------

K=8 RAL=14.5+0.5mm

----------

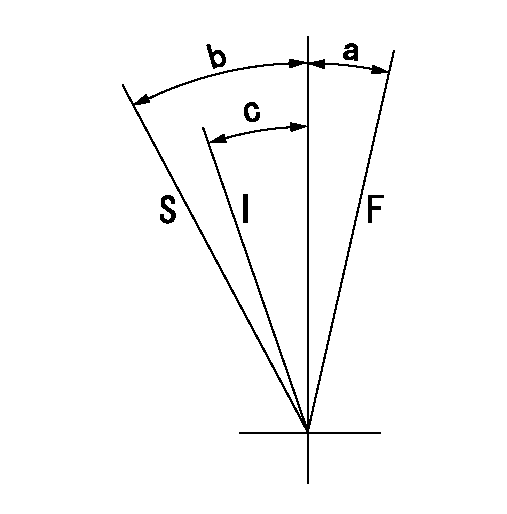

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=(14deg) b=32deg+-3deg c=(19deg)

----------

----------

a=(14deg) b=32deg+-3deg c=(19deg)

Information:

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Table 1

Required Parts

Qty Part Number Part Name

1 420-0939 Sleeve(1)

1 420-0940 Sleeve(2)

1 420-0941 Sleeve(3)

1 420-0942 Sleeve(4)

(1) Red

(2) Silver

(3) Gold

(4) GreenSleeve Rework procedure

Illustration 1 g06360367

Typical example of an injector - without sleeve

(A) Adjustment screw

(B) Locknut

Remove and retain adjustment screw (A). Remove and discard locknut (B).

Illustration 2 g06360368

Typical example of an injector - with sleeve

(1) Sleeve

(A) Adjustment screw

Insert appropriate sleeve (1) onto adjustment screw (A).

Have questions with 101891-6510?

Group cross 101891-6510 ZEXEL

Mitsubishi

101891-6510

9 400 616 220

3126185021

INJECTION-PUMP ASSEMBLY

8DC20

8DC20