Information injection-pump assembly

BOSCH

9 400 616 214

9400616214

ZEXEL

101803-1730

1018031730

MITSUBISHI

ME068099

me068099

Rating:

Service parts 101803-1730 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 616 214

9400616214

ZEXEL

101803-1730

1018031730

MITSUBISHI

ME068099

me068099

Zexel num

Bosch num

Firm num

Name

101803-1730

9 400 616 214

ME068099 MITSUBISHI

INJECTION-PUMP ASSEMBLY

8DC9 K

8DC9 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

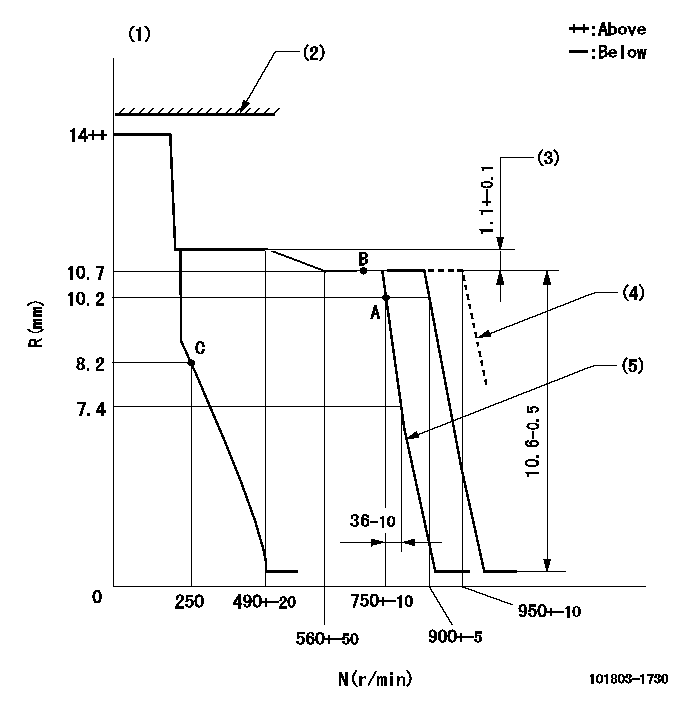

Injection quantity adjustment

Adjusting point

A

Rack position

10.2

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

102

98.5

105.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.7

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

115

111.5

118.5

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.2

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

13

10.4

15.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

550--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

800

Advance angle

deg.

1.6

1.1

2.1

Timer adjustment_04

Pump speed

r/min

900

Advance angle

deg.

2.3

1.8

2.8

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

6.5

6.5

6.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT not operating.

(3)Rack difference between N = N1 and N = N2

(4)At shipping

(5)Idle sub spring setting: L1.

----------

K=11 N1=450r/min N2=700r/min L1=7.2+-0.1mm

----------

----------

K=11 N1=450r/min N2=700r/min L1=7.2+-0.1mm

----------

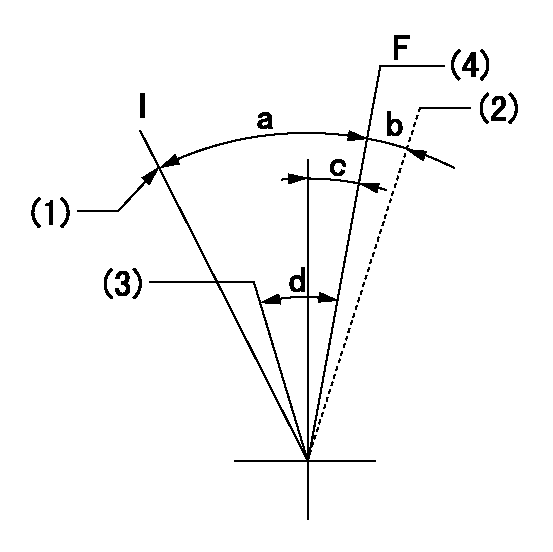

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)At shipping

(3)Pump speed = aa

(4)Pump speed = bb

----------

aa=750r/min bb=900r/min

----------

a=23deg+-5deg b=(2deg) c=4deg+-5deg d=5deg+-5deg

----------

aa=750r/min bb=900r/min

----------

a=23deg+-5deg b=(2deg) c=4deg+-5deg d=5deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At shipping

----------

----------

a=26deg+-5deg b=53deg+-5deg

----------

----------

a=26deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

An industry-wide issue has arisen with a specific type of deposit that forms in modern fuel injection systems and has a negative effect on operation.The C175 fuel system operates under higher pressures and temperatures than previous injection systems. Clearances between precision moving parts can be minute, typically less than 5 microns.A soapy type of deposit has been found in some C175 fuel injection systems. The formation of the deposits is being investigated by Caterpillar, along with the fuel industry and the petroleum industry.The cause of the deposits is complex, involving these kinds of variables:

Temperature

Pressure

Fuel chemistry

Water and contaminants in the fuelThe following symptoms are associated with the soapy deposits in the fuel injectors:

A loss of power

Excessive variations in exhaust temperature

Rough running

Hard starting, especially after allowing an engine to cool down before restarting

Stuck injectorsSevere deposits cause the injector to stick in one position, resulting in a cylinder that does not fire.To verify the presence of the deposits, the injector from a cold cylinder must be returned to Caterpillar.Solution

If the above symptoms are diagnosed or if the deposits are confirmed, use 343-6210 Cleaner (FUEL) to remove the deposits.The 343-6210 Cleaner (FUEL) is the only fuel system cleaner that has been tested and approved by Cat for use in Cat diesel engines.For sites that are more susceptible to injector deposits, maintain a supply of 343-6210 Cleaner (FUEL) in order to address the problem quickly.For more information, refer to the "Cat Diesel Fuel System Cleaner" topic in Operation and Maintenance Manual, SEBU6250, "Caterpillar Machine Fluids Recommendations" or in Operation and Maintenance Manual, SEBU6251, "Cat Commercial Diesel Engine Fluids Recommendations".Note: Depending on the amounts of deposits, the fuel filter may plug after initial use of the cleaner due to removal of the deposits. The frequency of the plugging will decrease as the fuel system returns to a condition that is clean and stable.Perform the following recommendations in order to reduce the potential for the formation of injector deposits:

Prior to filling the engine fuel tank with fuel from a storage tank, filter the fuel through an absolute filter of 4 µm.

Use filters of 4 µm filtration on the breathers of fuel storage tanks. In dusty environments, use a filter of 4 µm on the breather of the engine fuel tank.

Regularly monitor bulk fuel in order to ensure that concentrations of calcium, sodium, zinc, and magnesium are less than 1 ppm.

Caterpillar does not generally recommend the use of aftermarket fuel additives. If an aftermarket fuel additive is considered to be necessary, use the additive with caution. Follow the guidelines in the "Aftermarket Fuel Additives" topic in Operation and Maintenance Manual, SEBU6250, "Caterpillar Machine Fluids Recommendations" or in Operation and Maintenance Manual, SEBU6251, "Cat Commercial Diesel Engine Fluids Recommendations".

Make sure that the

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

An industry-wide issue has arisen with a specific type of deposit that forms in modern fuel injection systems and has a negative effect on operation.The C175 fuel system operates under higher pressures and temperatures than previous injection systems. Clearances between precision moving parts can be minute, typically less than 5 microns.A soapy type of deposit has been found in some C175 fuel injection systems. The formation of the deposits is being investigated by Caterpillar, along with the fuel industry and the petroleum industry.The cause of the deposits is complex, involving these kinds of variables:

Temperature

Pressure

Fuel chemistry

Water and contaminants in the fuelThe following symptoms are associated with the soapy deposits in the fuel injectors:

A loss of power

Excessive variations in exhaust temperature

Rough running

Hard starting, especially after allowing an engine to cool down before restarting

Stuck injectorsSevere deposits cause the injector to stick in one position, resulting in a cylinder that does not fire.To verify the presence of the deposits, the injector from a cold cylinder must be returned to Caterpillar.Solution

If the above symptoms are diagnosed or if the deposits are confirmed, use 343-6210 Cleaner (FUEL) to remove the deposits.The 343-6210 Cleaner (FUEL) is the only fuel system cleaner that has been tested and approved by Cat for use in Cat diesel engines.For sites that are more susceptible to injector deposits, maintain a supply of 343-6210 Cleaner (FUEL) in order to address the problem quickly.For more information, refer to the "Cat Diesel Fuel System Cleaner" topic in Operation and Maintenance Manual, SEBU6250, "Caterpillar Machine Fluids Recommendations" or in Operation and Maintenance Manual, SEBU6251, "Cat Commercial Diesel Engine Fluids Recommendations".Note: Depending on the amounts of deposits, the fuel filter may plug after initial use of the cleaner due to removal of the deposits. The frequency of the plugging will decrease as the fuel system returns to a condition that is clean and stable.Perform the following recommendations in order to reduce the potential for the formation of injector deposits:

Prior to filling the engine fuel tank with fuel from a storage tank, filter the fuel through an absolute filter of 4 µm.

Use filters of 4 µm filtration on the breathers of fuel storage tanks. In dusty environments, use a filter of 4 µm on the breather of the engine fuel tank.

Regularly monitor bulk fuel in order to ensure that concentrations of calcium, sodium, zinc, and magnesium are less than 1 ppm.

Caterpillar does not generally recommend the use of aftermarket fuel additives. If an aftermarket fuel additive is considered to be necessary, use the additive with caution. Follow the guidelines in the "Aftermarket Fuel Additives" topic in Operation and Maintenance Manual, SEBU6250, "Caterpillar Machine Fluids Recommendations" or in Operation and Maintenance Manual, SEBU6251, "Cat Commercial Diesel Engine Fluids Recommendations".

Make sure that the

Have questions with 101803-1730?

Group cross 101803-1730 ZEXEL

Mitsubishi

101803-1730

9 400 616 214

ME068099

INJECTION-PUMP ASSEMBLY

8DC9

8DC9