Information injection-pump assembly

BOSCH

9 400 610 185

9400610185

ZEXEL

101803-1700

1018031700

MITSUBISHI

ME069083

me069083

Rating:

Service parts 101803-1700 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

31261-30020

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 610 185

9400610185

ZEXEL

101803-1700

1018031700

MITSUBISHI

ME069083

me069083

Zexel num

Bosch num

Firm num

Name

101803-1700

9 400 610 185

ME069083 MITSUBISHI

INJECTION-PUMP ASSEMBLY

8DC9 K 14BH INJECTION PUMP ASSY PE8AD PE

8DC9 K 14BH INJECTION PUMP ASSY PE8AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

8

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

108.5

105

112

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.3+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

18

15.4

20.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

550--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

800

Advance angle

deg.

1.6

1.1

2.1

Timer adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

4

3.5

4.5

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

6.5

6.5

6.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

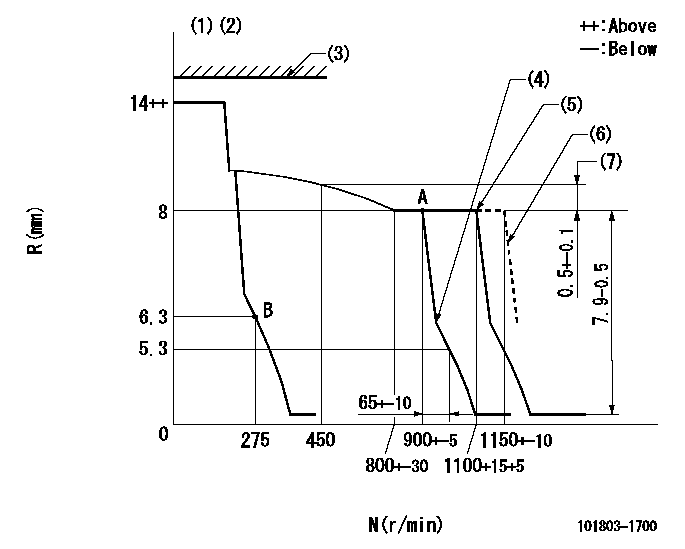

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)The torque control spring must does not have a set force.

(3)RACK LIMIT not operating.

(4)Idle sub spring setting: L1.

(5)Torque spring does not operate.

(6)At shipping

(7)Rack difference between N = N1 and N = N2

----------

K=15 L1=6.3+-0.1mm N1=900r/min N2=450r/min

----------

----------

K=15 L1=6.3+-0.1mm N1=900r/min N2=450r/min

----------

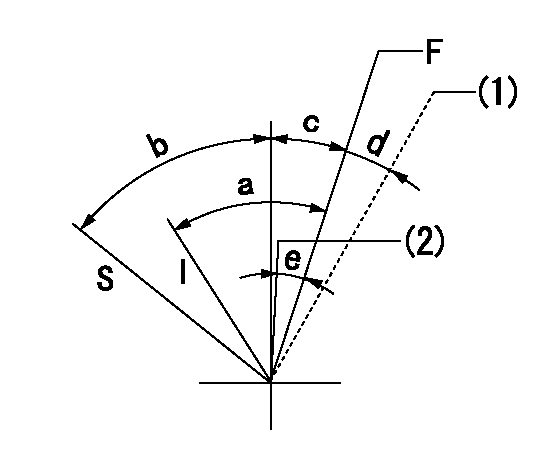

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)At shipping

(2)Pump speed = aa

----------

aa=900r/min

----------

a=24deg+-5deg b=32deg+-3deg c=12deg+-5deg d=(2deg) e=6deg+-5deg

----------

aa=900r/min

----------

a=24deg+-5deg b=32deg+-3deg c=12deg+-5deg d=(2deg) e=6deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=46deg+-5deg

----------

----------

a=19deg+-5deg b=46deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Illustration 62 g02807941

Remove the plug

Remove plug (2) .

Illustration 63 g02807956

Set speed by turning adjusting screw

Adjust speed. If Ng exceeds TMI specifications, tighten the adjusting screw. If Ng is less than the specified value, loosen the adjusting screw.

Illustration 64 g02807957

Adjust the maximum-speed stopper bolt

Adjust the maximum-speed stopper bolt until the speed at the start of high-speed control is Nf.

Check that the no-load maximum speed is Ng (described in Step 1). Continue adjustment until the specified value is obtained.

Illustration 65 g02807958

Increase pump speed to make sure that the control rack position reaches Ra.

Illustration 66 g02807959

Full-load Adjustment

Illustration 67 g02807997

Install the cover and adjust full-load stopper bolt

Install cover (3) on governor using bolts and lockwashers (2). Use caution when installing the cover to make sure that the O-ring seal is in the seal groove.

Illustration 68 g02807999

Position the control lever at maximum-speed position.

Adjust full-load stopper bolt (1) to the f"ull-load fuel injection quantity" position. See TMI for the specifications (Point A).

Install cap.Control Lever Angle Measurement

Illustration 69 g02808016

Measuring control lever angle at the "full-speed" and "idling" positions.

Measuring the control lever angle at the "idling" and "full" positions.

If the angle is not as specified by TMI, replace the shifters shim. If the control lever is positioned toward the "full" position, replace the shifters shim with a thicker one. When control lever is toward the "idling" position, replace the shim with a thinner one.Check Starting Delivery

Illustration 70 g02808018

Remove measurement adapter

Remove measurement adapter (1) .

Illustration 71 g02808038

Cap must be installed to check delivery rate

Install cap (2) .

Run pump at speed specified in TMI.

Check delivery rate with specifications listed in TMI.

Stop pump rotation.

Illustration 72 g02808058

Adjusting screw for setting fuel flow

If delivery rate does not meet TMI specifications, remove cap (2), loosen lock nut, and adjust screw (3). Adjusting screw outward decreases fuel flow and inward increases fuel flow.

Install cap (2) and recheck delivery rate. Repeat Steps 2 through 6 until delivery rate is at specified value.Lockwiring Caps of Adjustment Screws

All adjustment stops (screws) that directly affect engine performance should be lockwired after adjustment. Do not readjust any stop without using the test stand can adversely affect the engine and engine performance.

Have questions with 101803-1700?

Group cross 101803-1700 ZEXEL

Mitsubishi

101803-1700

9 400 610 185

ME069083

INJECTION-PUMP ASSEMBLY

8DC9

8DC9