Information injection-pump assembly

BOSCH

9 400 616 209

9400616209

ZEXEL

101803-1670

1018031670

MITSUBISHI

ME069795

me069795

Rating:

Include in #1:

101603-6960

as _

Cross reference number

BOSCH

9 400 616 209

9400616209

ZEXEL

101803-1670

1018031670

MITSUBISHI

ME069795

me069795

Zexel num

Bosch num

Firm num

Name

9 400 616 209

ME069795 MITSUBISHI

INJECTION-PUMP ASSEMBLY

8DC81 * K 14BH INJECTION PUMP ASSY PE8AD PE

8DC81 * K 14BH INJECTION PUMP ASSY PE8AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

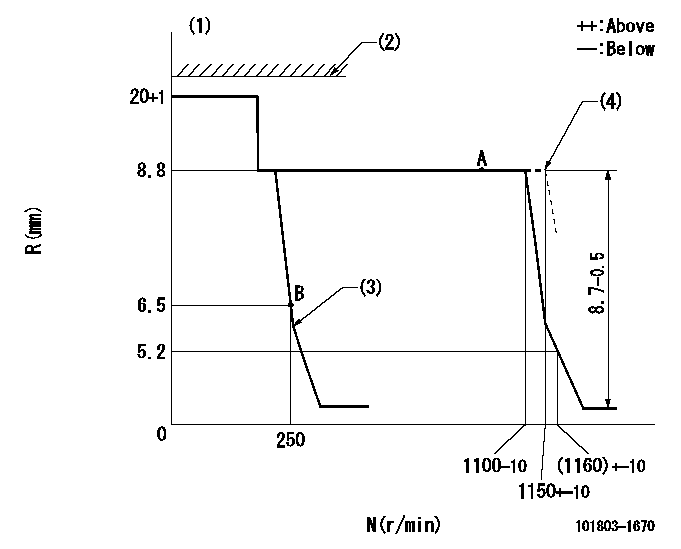

Injection quantity adjustment

Adjusting point

A

Rack position

8.8

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

115.4

111.9

118.9

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.5+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

15

12.4

17.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

550--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

750

Advance angle

deg.

1.6

1.1

2.1

Timer adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

4.2

3.7

4.7

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

6.5

6.5

6.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)RACK LIMIT not operating.

(3)Idle sub spring setting: L1.

(4)At shipping

----------

K=12 L1=6.5-0.2mm

----------

----------

K=12 L1=6.5-0.2mm

----------

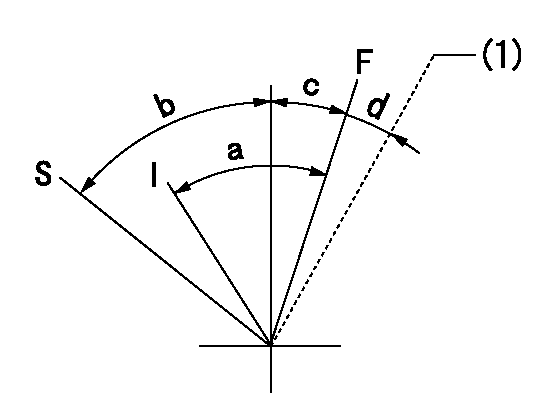

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)At shipping

----------

----------

a=29deg+-5deg b=32deg+-3deg c=15deg+-5deg d=(2deg)

----------

----------

a=29deg+-5deg b=32deg+-3deg c=15deg+-5deg d=(2deg)

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=46deg+-5deg

----------

----------

a=19deg+-5deg b=46deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Elevated sodium in the oil samples.Solution

If the source of the sodium cannot be isolated via other normal testing of individual components (water pumps, oil coolers, and so on), then complete the following procedure:

Shut down the engine and allow system to cool.

Flip the ground level shutdown switch on the truck front bumper and leave the switch engaged. This action disables the fuel injection.

Verify that the engine will crank but the engine does NOT start.

Pull the last exhaust manifold from each bank of the engine.

Pressurize the truck cooling system, refer to Testing and Adjusting, KENR5397 for additional information.

Hold pressure on the cooling system for no more than 10 minutes for the first test. If the leak is bad, holding the pressure too long could risk hydraulic lock.

Illustration 1 g06059950

While cranking the engine, shine a light up into the exhaust manifolds and look for cylinders that are puffing steam and white smoke.

Verify any leaks by pulling the exhaust thermocouple port from the exhaust runner on that cylinder. Check for signs of moisture/steaming in that exhaust runner.

Repair any leaking injector sleeve by replacing the head.

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Elevated sodium in the oil samples.Solution

If the source of the sodium cannot be isolated via other normal testing of individual components (water pumps, oil coolers, and so on), then complete the following procedure:

Shut down the engine and allow system to cool.

Flip the ground level shutdown switch on the truck front bumper and leave the switch engaged. This action disables the fuel injection.

Verify that the engine will crank but the engine does NOT start.

Pull the last exhaust manifold from each bank of the engine.

Pressurize the truck cooling system, refer to Testing and Adjusting, KENR5397 for additional information.

Hold pressure on the cooling system for no more than 10 minutes for the first test. If the leak is bad, holding the pressure too long could risk hydraulic lock.

Illustration 1 g06059950

While cranking the engine, shine a light up into the exhaust manifolds and look for cylinders that are puffing steam and white smoke.

Verify any leaks by pulling the exhaust thermocouple port from the exhaust runner on that cylinder. Check for signs of moisture/steaming in that exhaust runner.

Repair any leaking injector sleeve by replacing the head.