Information injection-pump assembly

ZEXEL

101801-9020

1018019020

Rating:

Service parts 101801-9020 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Cross reference number

ZEXEL

101801-9020

1018019020

Zexel num

Bosch num

Firm num

Name

101801-9020

DPICO

INJECTION-PUMP ASSEMBLY

8DC9 * Q

8DC9 * Q

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4420

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

8

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

108.5

105

112

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.3+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

18

15.4

20.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

1.6

1.1

2.1

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

4

3.5

4.5

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

6.5

6.5

6.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

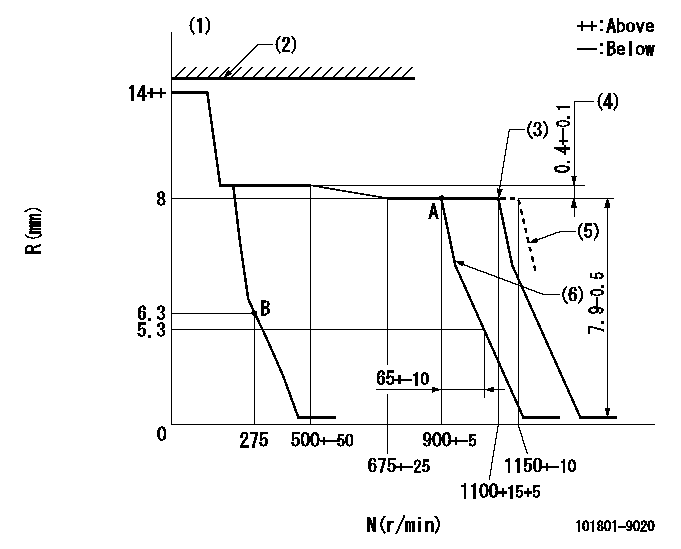

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT not operating.

(3)Torque spring does not operate.

(4)Rack difference between N = N1 and N = N2

(5)At delivery

(6)Idle sub spring setting: L1.

----------

K=15 N1=900r/min N2=450r/min L1=6.3+-0.1mm

----------

----------

K=15 N1=900r/min N2=450r/min L1=6.3+-0.1mm

----------

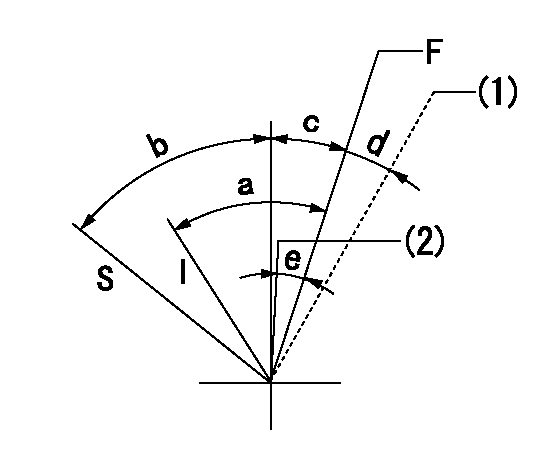

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)At delivery

(2)When pump speed set at aa

----------

aa=900r/min

----------

a=24deg+-5deg b=32deg+-3deg c=12deg+-5deg d=(2deg) e=6deg+-5deg

----------

aa=900r/min

----------

a=24deg+-5deg b=32deg+-3deg c=12deg+-5deg d=(2deg) e=6deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=46deg+-5deg

----------

----------

a=19deg+-5deg b=46deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

In the New Systems, Refilled Systems, and converted systemsEvery year: add to it hours: ever year or every 2000 hours, whichever comes first.When referring to the Service Life in table 1, use the interval that occurs first. These coolant change intervals are only achievable with annual S O S Services Level 2 coolant sampling analysis.Refer to the engine Operation and Maintenance Manual for the correct interval for replacement of the cooling system water temperature regulator.Note: For engines that require a maximum of 20% glycol, make sure that the amount of additive in the final mix is appropriate. Example of mixing a 20% glycol solution is given in Table 3.

Table 3

Example of Mixing Up a 20% Glycol Coolant (1)

Total Volume of the Cooling System Add the Following:

ELC Concentrate ELI Concentrate Water

10 Gallons 2 Gallons 0.5 Gallons 7.5 Gallons

(1) Volumes can also be in liters as long as all the volume units are consistentExtended life coolants require the one time maintenance addition of an extender at coolant service mid-life. For commercial coolants, do NOT use an extender with a coolant unless the extender has been approved by the coolant manufacturer for use with the coolant. The coolant manufacturer is responsible to ensure compatibility and acceptable performance. Failure to follow these recommendations can result in shortened cooling system component life.Conventional coolants require the maintenance addition of SCA throughout the expected life. For commercial coolants, do NOT use an SCA unless approved by the coolant supplier for use with the coolant. The coolant manufacturer is responsible to ensure compatibility and acceptable performance."ASTM D6210" require coolants that are properly dosed with SCA and that are in a properly maintained cooling system in normal service to be suitable for use for a maximum of 2 years. The suitability for use requirement is the direct responsibility of the coolant manufacturer and SCA manufacturer. Consult with the coolant and/or SCA manufacturer concerning the suitability of the products for use in a given application.Cat DEAC is fully formulated and does not require a treatment with an SCA at the initial fill.A commercial heavy-duty coolant/antifreeze that meets the "ASTM D6210"specification does not require a treatment with an SCA at the initial fill.Commercial Heavy Duty coolants that meet only "ASTM D4985" specification are not recommended for Caterpillar applications. These coolants may not provide the performance characteristics needed for heavy duty applications. Cat coolants and the coolants detailed in Table 1 and in this Chapter are formulated to offer the required performance in Cat engines. Refer to Table 1 for Cat coolants recommendations.Cat ELC, Cat ELI, Cat DEAC, Cat Extender, and Cat SCA are available in several container sizes. The availability of part numbers will vary by the region. Consult your Cat dealer.In stationary and marine engine applications that do not require protection from boiling or freezing, except as noted in Table 2, Cat ELI in water or SCA and water are acceptable.

Table 3

Example of Mixing Up a 20% Glycol Coolant (1)

Total Volume of the Cooling System Add the Following:

ELC Concentrate ELI Concentrate Water

10 Gallons 2 Gallons 0.5 Gallons 7.5 Gallons

(1) Volumes can also be in liters as long as all the volume units are consistentExtended life coolants require the one time maintenance addition of an extender at coolant service mid-life. For commercial coolants, do NOT use an extender with a coolant unless the extender has been approved by the coolant manufacturer for use with the coolant. The coolant manufacturer is responsible to ensure compatibility and acceptable performance. Failure to follow these recommendations can result in shortened cooling system component life.Conventional coolants require the maintenance addition of SCA throughout the expected life. For commercial coolants, do NOT use an SCA unless approved by the coolant supplier for use with the coolant. The coolant manufacturer is responsible to ensure compatibility and acceptable performance."ASTM D6210" require coolants that are properly dosed with SCA and that are in a properly maintained cooling system in normal service to be suitable for use for a maximum of 2 years. The suitability for use requirement is the direct responsibility of the coolant manufacturer and SCA manufacturer. Consult with the coolant and/or SCA manufacturer concerning the suitability of the products for use in a given application.Cat DEAC is fully formulated and does not require a treatment with an SCA at the initial fill.A commercial heavy-duty coolant/antifreeze that meets the "ASTM D6210"specification does not require a treatment with an SCA at the initial fill.Commercial Heavy Duty coolants that meet only "ASTM D4985" specification are not recommended for Caterpillar applications. These coolants may not provide the performance characteristics needed for heavy duty applications. Cat coolants and the coolants detailed in Table 1 and in this Chapter are formulated to offer the required performance in Cat engines. Refer to Table 1 for Cat coolants recommendations.Cat ELC, Cat ELI, Cat DEAC, Cat Extender, and Cat SCA are available in several container sizes. The availability of part numbers will vary by the region. Consult your Cat dealer.In stationary and marine engine applications that do not require protection from boiling or freezing, except as noted in Table 2, Cat ELI in water or SCA and water are acceptable.

Have questions with 101801-9020?

Group cross 101801-9020 ZEXEL

Hyundai

Dpico

101801-9020

INJECTION-PUMP ASSEMBLY

8DC9

8DC9