Information injection-pump assembly

BOSCH

9 400 616 177

9400616177

ZEXEL

101697-9120

1016979120

NISSAN-DIESEL

16714Z5616

16714z5616

Rating:

Include in #1:

106871-7260

as _

Cross reference number

BOSCH

9 400 616 177

9400616177

ZEXEL

101697-9120

1016979120

NISSAN-DIESEL

16714Z5616

16714z5616

Zexel num

Bosch num

Firm num

Name

101697-9120

9 400 616 177

16714Z5616 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FE6T K

FE6T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-1520

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

13.6

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

92.5

90.5

94.5

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.7+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

17

15.2

18.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.6)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

92.5

91.5

93.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

40

40

Boost pressure

mmHg

300

300

Injection quantity adjustment_04

Adjusting point

B

Rack position

(R1+0.3)

+0.05-0.

15

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

99.5

96.3

102.7

Fixing the lever

*

Boost pressure

kPa

40

40

Boost pressure

mmHg

300

300

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2(R1-0.

2)

Pump speed

r/min

420

420

420

Average injection quantity

mm3/st.

80

76.8

83.2

Fixing the lever

*

Boost pressure

kPa

40

40

Boost pressure

mmHg

300

300

Injection quantity adjustment_06

Adjusting point

D

Rack position

R2-1.8

Pump speed

r/min

420

420

420

Average injection quantity

mm3/st.

46

44

48

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

105

105

125

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

420

420

420

Rack position

R2-1.8

Boost pressure

kPa

12

10.7

13.3

Boost pressure

mmHg

90

80

100

Boost compensator adjustment_02

Pump speed

r/min

420

420

420

Rack position

R2(R1-0.

2)

Boost pressure

kPa

26.7

26.7

26.7

Boost pressure

mmHg

200

200

200

Timer adjustment

Pump speed

r/min

1170--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1120

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

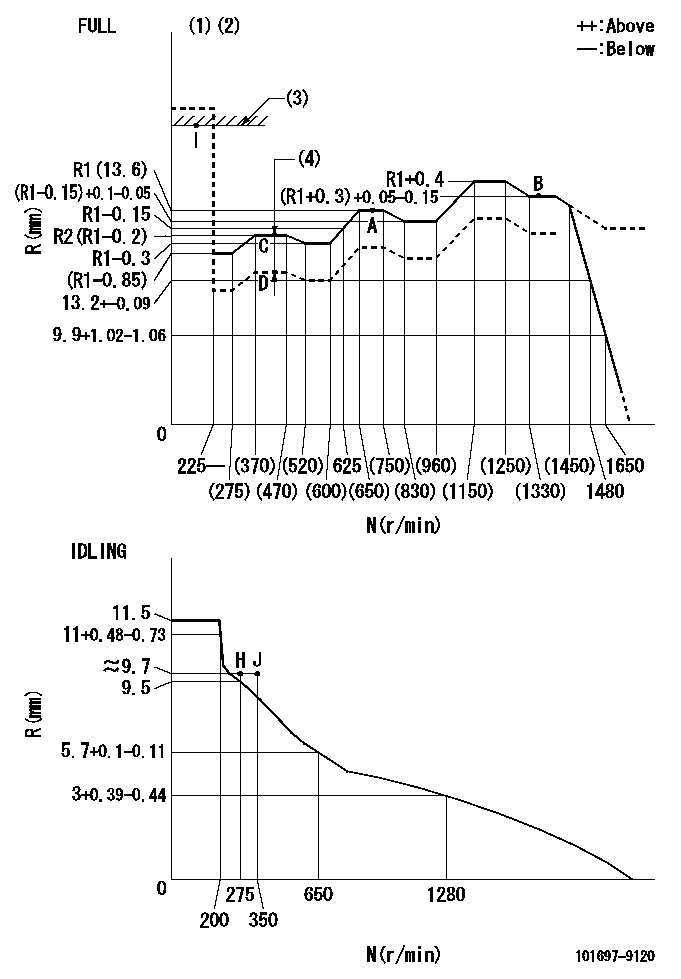

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

----------

T1=M68 BCL=1.8+-0.1mm

----------

----------

T1=M68 BCL=1.8+-0.1mm

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=36mm

----------

a=26deg+-5deg b=39deg+-3deg

----------

aa=36mm

----------

a=26deg+-5deg b=39deg+-3deg

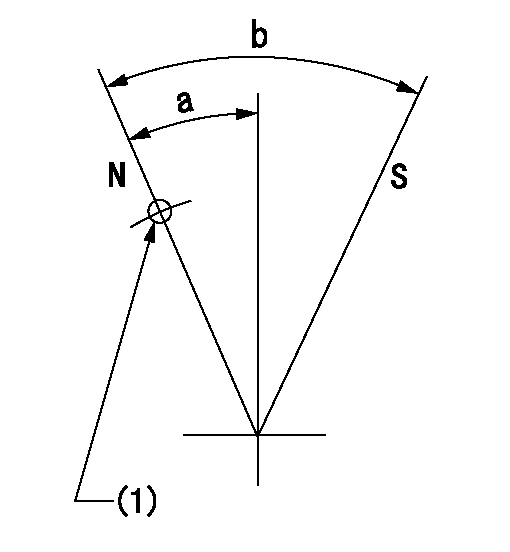

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=42mm

----------

a=27deg+-5deg b=40deg+-5deg

----------

aa=42mm

----------

a=27deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

Introduction

The following Special Instruction must be used to package a DPF for a core return.

Wear goggles, gloves, protective clothing, and a National Institute for Occupational Safety and Health (NIOSH) approved P95 or N95 half-face respirator when handling a used Diesel Particulate Filter or Catalytic Converter Muffler. Failure to do so could result in personal injury.

Note: Whenever the filter is replaced the engine ash model must be reset. Refer to the section below for information on how to reset the ash model.Reset the Engine Ash Model

The engine ash model must be reset whenever the filter is cleaned or replaced. Reseting the ash model places the DPF volume back to the "Clean State". The resetting will allow the regeneration of the DPF to function properly.

Use Cat ET to access the configuration parameters. Select "Service" from the top menu then select "Service Procedures" then select "DPF Ash Service" from the menu in the service tool.

Choose the correct replacement type of diesel particulate filter in the menu that appears. The types of replacements for the diesel particulate filter are the following:

"Field cleaned" A DPF that has been cleaned and reapplied.

"New" A new DPF replacement.

"Remanufactured" A remanufactured DPF replacement.

Once the reset is completed, a log of the reset is captured and visible as a new row of information in the "DPF Ash Service" screen. Resetting the engine ash model does not reset the soot level.

Perform a "Manual DPF Regeneration" with Cat® ET to reset the soot levelPackaging Instructions

Note: The replacement DPF will be packaged with a bag and zip-tie that are used to repackage the DPF that has been removed.

Place the DPF being returned in the enclosed bag and seal the bag with the enclosed zip-tie.

Place the enclosed warning label on the outside of the bag.

Place half of the foam insert on the bottom of the original shipping box with the cut out in the insert facing up.

Place the DPF into the box fitting the DPF into the cut out in the insert.

Place the second half of the foam insert on to of the DPF with the cut out in the insert facing down onto the DPF.

Seal the box with packing tape.Note: If the package weighs over 16 kg (35 lb), additional tape or banding might be required.

Label the package for return shipment.

The following Special Instruction must be used to package a DPF for a core return.

Wear goggles, gloves, protective clothing, and a National Institute for Occupational Safety and Health (NIOSH) approved P95 or N95 half-face respirator when handling a used Diesel Particulate Filter or Catalytic Converter Muffler. Failure to do so could result in personal injury.

Note: Whenever the filter is replaced the engine ash model must be reset. Refer to the section below for information on how to reset the ash model.Reset the Engine Ash Model

The engine ash model must be reset whenever the filter is cleaned or replaced. Reseting the ash model places the DPF volume back to the "Clean State". The resetting will allow the regeneration of the DPF to function properly.

Use Cat ET to access the configuration parameters. Select "Service" from the top menu then select "Service Procedures" then select "DPF Ash Service" from the menu in the service tool.

Choose the correct replacement type of diesel particulate filter in the menu that appears. The types of replacements for the diesel particulate filter are the following:

"Field cleaned" A DPF that has been cleaned and reapplied.

"New" A new DPF replacement.

"Remanufactured" A remanufactured DPF replacement.

Once the reset is completed, a log of the reset is captured and visible as a new row of information in the "DPF Ash Service" screen. Resetting the engine ash model does not reset the soot level.

Perform a "Manual DPF Regeneration" with Cat® ET to reset the soot levelPackaging Instructions

Note: The replacement DPF will be packaged with a bag and zip-tie that are used to repackage the DPF that has been removed.

Place the DPF being returned in the enclosed bag and seal the bag with the enclosed zip-tie.

Place the enclosed warning label on the outside of the bag.

Place half of the foam insert on the bottom of the original shipping box with the cut out in the insert facing up.

Place the DPF into the box fitting the DPF into the cut out in the insert.

Place the second half of the foam insert on to of the DPF with the cut out in the insert facing down onto the DPF.

Seal the box with packing tape.Note: If the package weighs over 16 kg (35 lb), additional tape or banding might be required.

Label the package for return shipment.

Have questions with 101697-9120?

Group cross 101697-9120 ZEXEL

Nissan-Diesel

101697-9120

9 400 616 177

16714Z5616

INJECTION-PUMP ASSEMBLY

FE6T

FE6T