Information injection-pump assembly

BOSCH

9 400 616 159

9400616159

ZEXEL

101696-9893

1016969893

NISSAN-DIESEL

16713Z6963

16713z6963

Rating:

Include in #1:

106691-2011

as _

Cross reference number

BOSCH

9 400 616 159

9400616159

ZEXEL

101696-9893

1016969893

NISSAN-DIESEL

16713Z6963

16713z6963

Zexel num

Bosch num

Firm num

Name

101696-9893

9 400 616 159

16713Z6963 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FE6TA K

FE6TA K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8260

Bosch type code

9 430 610 133

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

18

Opening pressure

kgf/cm2

184

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131425-0420

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.05

3.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.9

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

102

100.4

103.6

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.2+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

20

18.2

21.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.9)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

102

101

103

Basic

*

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+1.15

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

100

96

104

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2(R1+0.

15)

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

114.5

110.5

118.5

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_06

Adjusting point

D

Rack position

(R2-1.4)

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

73.5

71.5

75.5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

120

120

130

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

400

400

400

Rack position

(R2-1.4)

Boost pressure

kPa

6.7

5.4

8

Boost pressure

mmHg

50

40

60

Boost compensator adjustment_02

Pump speed

r/min

400

400

400

Rack position

R2(R1+0.

15)

Boost pressure

kPa

20

20

20

Boost pressure

mmHg

150

150

150

Timer adjustment

Pump speed

r/min

-

Advance angle

deg.

1

0.5

1.5

Remarks

Measure speed (beginning of operation).

Measure speed (beginning of operation).

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

4.5

4

5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

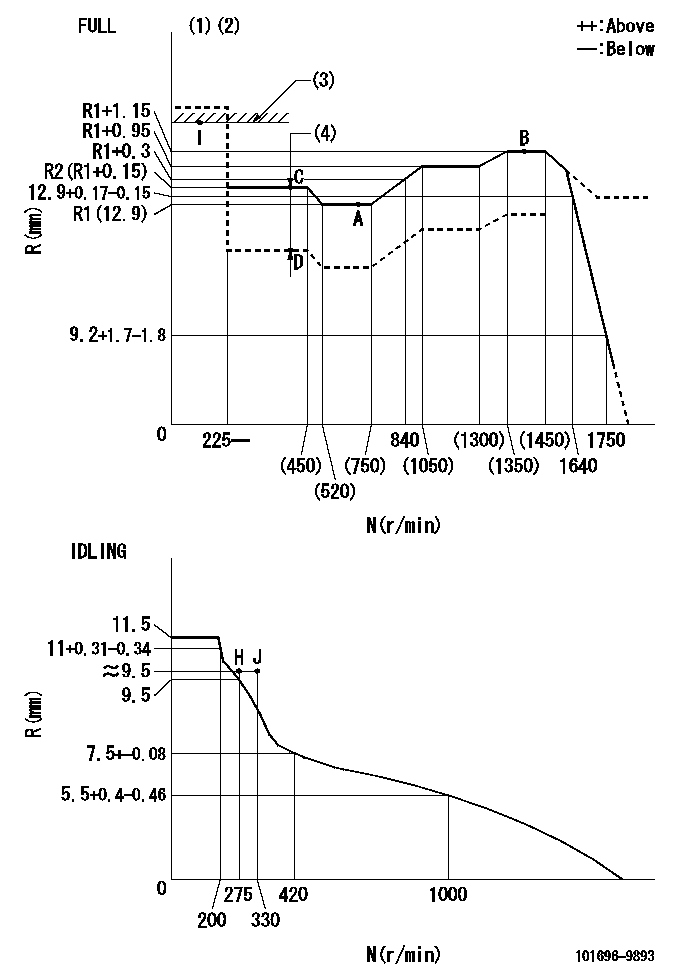

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

----------

T1=M71 BCL=(1.4)mm

----------

----------

T1=M71 BCL=(1.4)mm

----------

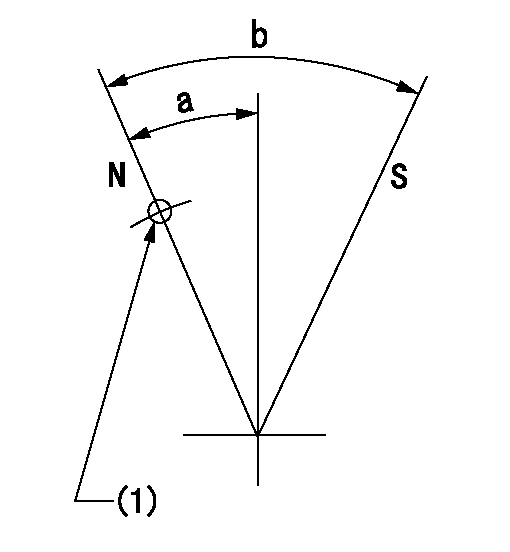

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=39mm

----------

a=20deg+-5deg b=40.5deg+-3deg

----------

aa=39mm

----------

a=20deg+-5deg b=40.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=42mm

----------

a=25deg+-5deg b=40deg+-5deg

----------

aa=42mm

----------

a=25deg+-5deg b=40deg+-5deg

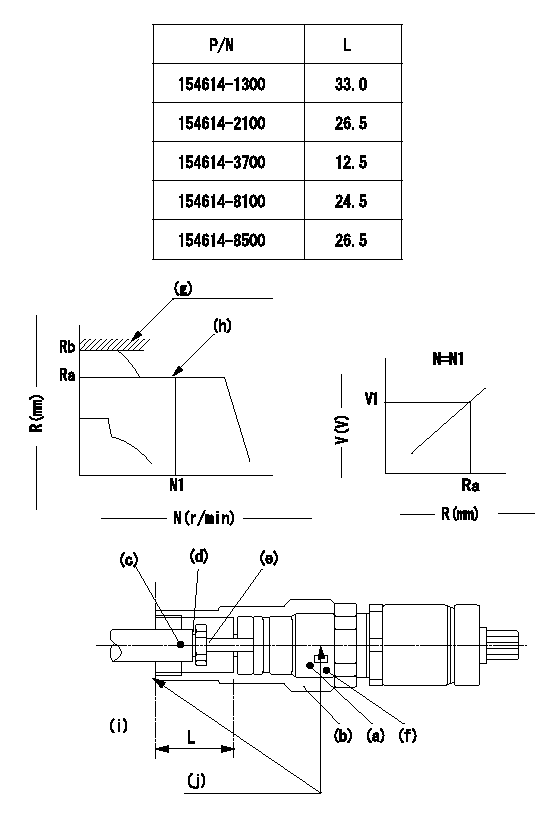

0000001501 RACK SENSOR

(g) rack limit

(h) rack sensor performance confirmation position

(i) pump end face

(j) Apply red paint.

Rack sensor adjustment (-5*20, threaded type, with A type rack limiter)

1. Rack limit adjustment

(1)When installing joint (b), select a shim (d) so that the rack limit rack position is Rb and the injection quantity is Qa.

(2)Install rod (E) to the rack (c).

(3)Select a joint (b) from the table above so that the distance from the pump end face to the rod (e) is L - 0.2 mm at rack position Rb.

2. Rack sensor adjustment

(1)Screw in the bobbin (A) until it contacts the joint (B).

(2)Fix the lever and set the pump speed at N1 and the rack position at Ra.

(3)Adjust the amount that the bobbin (a) is screwed in so that the amp's output voltage is V1. Then, fix using nut (f).

(4)Set the lever at the full speed side and confirm that the amp's output voltage is V1.

(5)Stick the caution plate on the top of the joint and apply red paint to the joint (b) and nut (f) join, and to the pump end face and joint (b) join.

Speed N1, Rack position = Ra, output voltage V1+-0.01 (V), rack sensor supply voltage 5+-0.01 (V)

----------

Qa=120+10mm3/st Ra=R1(12.9)mm N1=700r/min V1=3+-0.01V

----------

----------

Qa=120+10mm3/st Ra=R1(12.9)mm N1=700r/min V1=3+-0.01V

----------

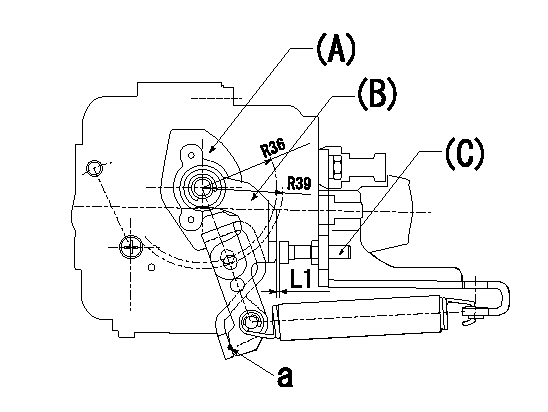

0000001601 LEVER

(a) Speed lever

(B) Accelerator lever

(C) Accelerator lever stopper bolt

1. Accelerator lever setting method

With the speed lever in the idling position, back off the accelerator lever stopper bolt L1 from where it contacts point a. (Back off 1+0.5 turns and set.)

----------

L1=1+0.5mm

----------

----------

L1=1+0.5mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Illustration 10 g00562677

Long strings of text will crowd the screen. Keep the custom text as short as possible. If the screen is unreadable shorten the text. Touching the "Done" button returns you to the "Language Conversion" screen. Setup of the Communications

The next two windows are for the setup of communications. The screens are for the two Modbus RTU ports. Port 1 is RS-485 and Port 2 is RS-232C.The "Engine Setup (plc-Baud)" window allows a baud rate to be selected for the two ports. The"Engine Setup (plc-Address)" window is used for setting the external address.Note: Refer to sheet 22 of the MMS System Schematics for cable connections and information.Note: Refer to Systems Operation, "Signal Listing". This is a detailed list of all the Modbus output registers.

Illustration 11 g00594475

Illustration 12 g00594478

Auxiliary Options

Illustration 13 g00594454

Note: If your MMS has been customized at time of sale, some of these options may not be available.The user can configure 4 of the system's input. The terminal blocks for 2 RTDS are located in the MECP. The terminal blocks for 2 4-20mA transducers are also located in the MECP. The spare input may be used for any RTD or 4-20mA analog input.Touch the "Auxiliary Options" picture in order to configure the auxiliary input. Touch the "Auxiliary Options" picture in order to configure the auxiliary outputs. You are now on the "MMS Customation" screen."Edit Gauges" Screen

Touch the "Edit Gauges" button. Four auxiliary analog inputs are available. Each input may be added to the MMS display.Two of the inputs are for RTDS. The RTDS are set within a range of 0 °C (32.0 °F) to 150 °C (302.0 °F). The two remaining inputs are 4-20 mA. The inputs must have ranges that can be configured. This provides appropriate scaling for the numerical display. The ranges also provide appropriate scaling for the graphic display.

Illustration 14 g00594484

Auxiliary Temperature Input Setup

Touch the gauge in order to activate the specific "Auxiliary Temperature Gauge". The green check mark indicates that the gauge is activated.

Illustration 15 g00562687

Setup of the Auxiliary Analog Input

Touch the gauge in order to activate the specific "Auxiliary Analog Gauge". The green check mark indicates that the gauge is selected. Touch the "Gauge Range" box. This will display a numeric keypad. Enter the maximum value for the analog input. Touch the "OK" key. The scaling of the analog input start at zero.Touch the "UUU__XXXXXXXXX" box. This will display a keyboard. Type first 3 characters and then type a space. Type the label for the auxiliary analog input. Touch the "Enter" key in order to proceed.Customize the Auxiliary Labels

Note: The external keyboard will be required for this function.A keyboard with a PS/2 connection may be used. Plug the keyboard into the "keyboard" connection on the back of the PC.You are on the "MMS Customization" screen. Touch the "Edit Auxiliary Labels" button.

Illustration 16 g00594490

Labels for the Auxiliary Alarms

Note: The external keyboard will be required for this function. A keyboard with a PS/2 connection may be used. Plug the keyboard into the "keyboard" connection on the back of the PC.Four

Have questions with 101696-9893?

Group cross 101696-9893 ZEXEL

Nissan-Diesel

China

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

101696-9893

9 400 616 159

16713Z6963

INJECTION-PUMP ASSEMBLY

FE6TA

FE6TA