Information injection-pump assembly

BOSCH

9 400 610 819

9400610819

ZEXEL

101696-9770

1016969770

NISSAN-DIESEL

16713Z6719

16713z6719

Rating:

Service parts 101696-9770 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-Z5672

12.

Open Pre:MPa(Kqf/cm2)

16.7{170}/19.6{200}

14.

NOZZLE

Cross reference number

BOSCH

9 400 610 819

9400610819

ZEXEL

101696-9770

1016969770

NISSAN-DIESEL

16713Z6719

16713z6719

Zexel num

Bosch num

Firm num

Name

9 400 610 819

16713Z6719 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FE6TA * K 14BF PE6AD PE

FE6TA * K 14BF PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8260

Bosch type code

9 430 610 133

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

18

Opening pressure

kgf/cm2

184

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131425-0420

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.05

3.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

13

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

103.5

101.9

105.1

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.2+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

20

18.2

21.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

103.5

102.5

104.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

28

28

Boost pressure

mmHg

210

210

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+1.55

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

107.5

103.5

111.5

Fixing the lever

*

Boost pressure

kPa

28

28

Boost pressure

mmHg

210

210

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2(R1-0.

15)

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

103

99

107

Fixing the lever

*

Boost pressure

kPa

28

28

Boost pressure

mmHg

210

210

Injection quantity adjustment_06

Adjusting point

D

Rack position

R2-1.25

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

75

71

79

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

120

120

130

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

400

400

400

Rack position

R2-1.25

Boost pressure

kPa

4

2.7

5.3

Boost pressure

mmHg

30

20

40

Boost compensator adjustment_02

Pump speed

r/min

400

400

400

Rack position

R2(R1-0.

15)

Boost pressure

kPa

14.7

14.7

14.7

Boost pressure

mmHg

110

110

110

Timer adjustment

Pump speed

r/min

-

Advance angle

deg.

1

0.5

1.5

Remarks

Measure speed (beginning of operation).

Measure speed (beginning of operation).

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

4.5

4

5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

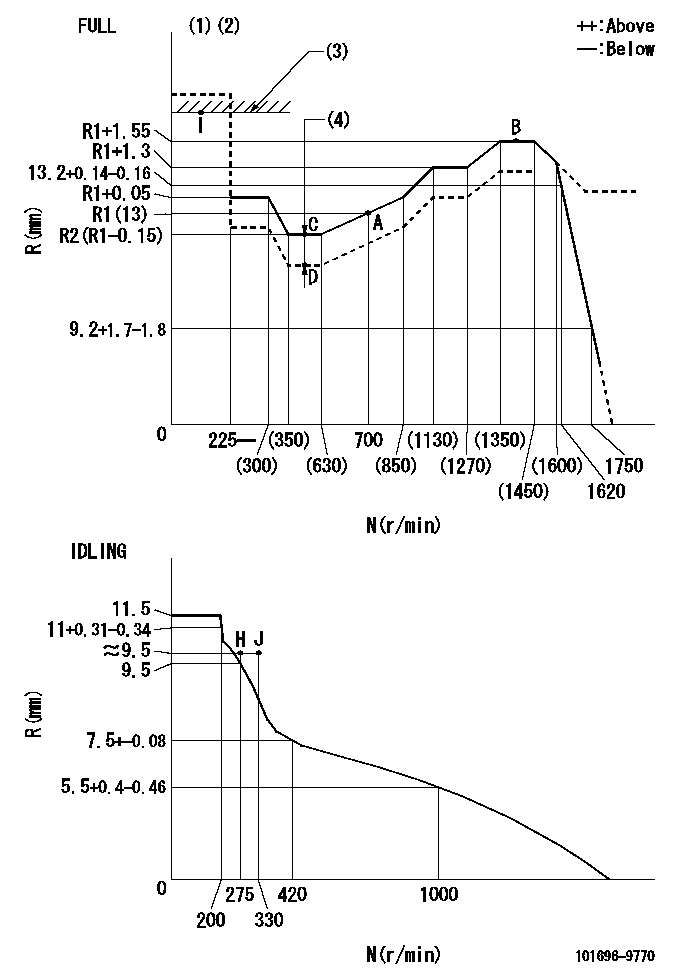

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

----------

T1=M49 BCL=1.25+-0.1mm

----------

----------

T1=M49 BCL=1.25+-0.1mm

----------

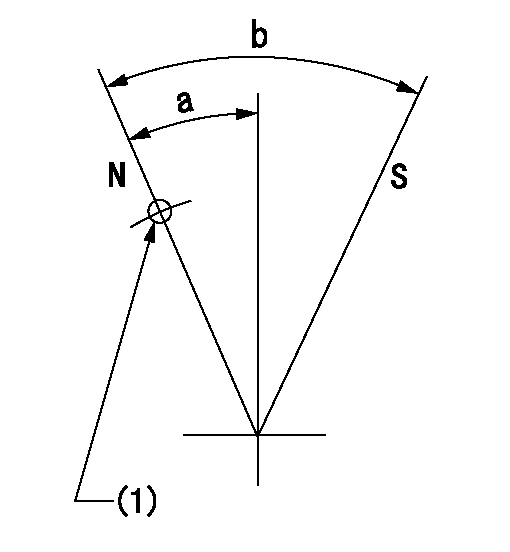

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=36mm

----------

a=25deg+-5deg b=40.5deg+-3deg

----------

aa=36mm

----------

a=25deg+-5deg b=40.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=42mm

----------

a=25deg+-5deg b=40deg+-5deg

----------

aa=42mm

----------

a=25deg+-5deg b=40deg+-5deg

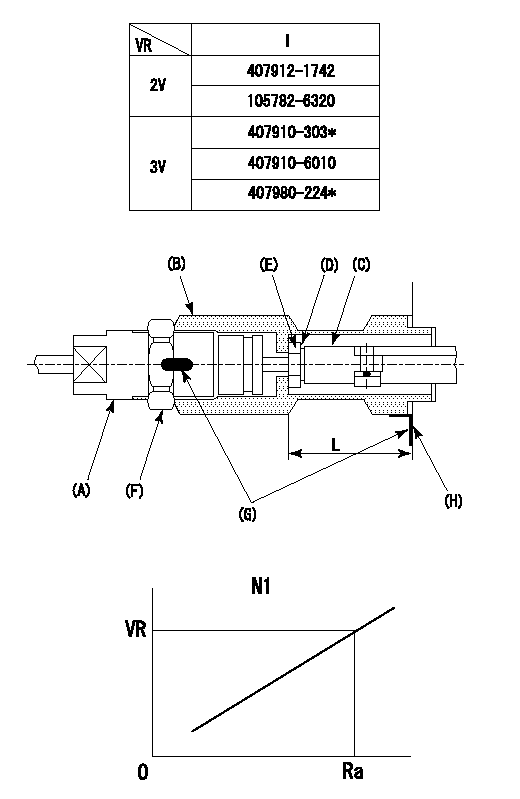

0000001501 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack limit adjustment

(1)Fix the rack at the rack limit position Ra.

(2)Install the shim (D) to the rod (C) and tighten nut (E).

(3)Select a shim (D) so that the distance between the end surface of the pump and the nut (E) is L.

(4)Release the rack fixing and mount the joint (B) and fix.

(5)At this time, confirm that the shim (D) does not interfere with the joint (B).

2. Rack sensor adjustment (-0420)

(1)Screw in the bobbin (A) until it contacts the joint (B).

(2)Fix the speed control lever at the full side.

(3)Set the speed to N1 r/min.

(4)Adjust the depth that the bobbin (A) is screwed in so that the control unit's rack sensor output voltage is VR+-0.01 (V), then tighten the nut (F).

(5)Adjust the bobbin (A) so that the rack sensor's output voltage is VR.

(6)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

L=33-0.2mm N1=700r/min Ra=R1(13)mm

----------

----------

L=33-0.2mm N1=700r/min Ra=R1(13)mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Problem 5

The engine shutdown occurs after the engine runs for more than 3 minutes.

Check the overspeed setting on the electronic speed switch (ESS).

Observe the indicator lamp on the ESS.

Reset the air shutoff lever, if equipped.

Crank the engine. Stop the engine with the emergency stop switch, if trouble occurs.Result

The indicator lamp on the ESS is turned on.Overspeed is indicated as the cause of the engine shutdown. Press the "RESET" button of the ESS. Find the cause of the overspeed. Refer to Testing and Adjusting, "Overspeed Verification Test" and Testing and Adjusting, "Overspeed Calibration". If the overspeed is adjusted properly and the problem persists, check the shielded cable. Only the shield should be connected to terminal 2 on the ESS. STOP.

The indicator lamp is turned off.Go to Step 2.

Check the protection switches.

Remove the jumper that is between terminals (TS-9) and (TS-10) of the junction box.

Crank the engine. Stop the engine with the emergency stop switch, if trouble occurs.Result

The engine starts and the engine runs.The problem is in the oil pressure switches or the water temperature contactor switch. Go to Step 8 of "Problem 1".

The engine starts but engine shutdown occurs immediately.Go to Step 1 of "Problem 3".

The engine starts and the engine runs but engine shutdown occurs after the engine runs for more than 3 minutes.Go to Step 3.

The engine cranks but the engine does not start.Go to Step 1 of "Problem 1".

Check the start/stop switch.

Disconnect the wire in the junction box that connects terminal (SR1-85) of the slave relay (SR1) to terminal (TD-7) of the time delay relay (TD).

Disconnect the wire from terminal (TD-7) and insulate the exposed wire.

Crank the engine. Stop the engine with the emergency stop switch, if trouble occurs.Result

The engine starts and the engine runs.The start/stop switch has a short circuit or a wiring problem is causing a voltage at terminal (TD-7). Reconnect the wire to the terminal.

Check the start/stop switch.

Disconnect the wire that runs from the STOP position of terminal (SSS-6) to terminal (TD-6). Terminal (SSS-6) is on the start/stop switch.

Disconnect the wire at terminal (TD-7).

Crank the engine. Stop the engine with the emergency stop switch, if trouble occurs.Result

The engine starts and the engine runs.The start/stop switch is faulty. Replace the switch. STOP.

Engine shutdown still occurs.Reconnect the wire to terminal (TD-7). Go to Step 5

Check the slave relay (SR1).

Disconnect the wire that connects terminal (TS-10) of the junction box to terminal (TD-6) of the time delay relay.

Disconnect the wire at terminal (TD-6).

Crank the engine. Stop the engine with the emergency stop switch, if trouble occurs.Result

The engine starts and the engine runs.The start/stop switch is faulty. Replace the start/stop switch. STOP.

Engine shutdown still occurs.The contacts of SR1 periodically close. The problem may also be with the governor or the fuel supply to the engine. Refer to the Engine Service Manual. If a 2301A Electric Governor is used, the SR1 contacts may be opening. Refer to 2301A Electric Governor Service Manual, SENR3585. Test SR1. Refer to Testing and Adjusting, "Slave Relay Test".Problem 6

Engine shutdown does not occur

The engine shutdown occurs after the engine runs for more than 3 minutes.

Check the overspeed setting on the electronic speed switch (ESS).

Observe the indicator lamp on the ESS.

Reset the air shutoff lever, if equipped.

Crank the engine. Stop the engine with the emergency stop switch, if trouble occurs.Result

The indicator lamp on the ESS is turned on.Overspeed is indicated as the cause of the engine shutdown. Press the "RESET" button of the ESS. Find the cause of the overspeed. Refer to Testing and Adjusting, "Overspeed Verification Test" and Testing and Adjusting, "Overspeed Calibration". If the overspeed is adjusted properly and the problem persists, check the shielded cable. Only the shield should be connected to terminal 2 on the ESS. STOP.

The indicator lamp is turned off.Go to Step 2.

Check the protection switches.

Remove the jumper that is between terminals (TS-9) and (TS-10) of the junction box.

Crank the engine. Stop the engine with the emergency stop switch, if trouble occurs.Result

The engine starts and the engine runs.The problem is in the oil pressure switches or the water temperature contactor switch. Go to Step 8 of "Problem 1".

The engine starts but engine shutdown occurs immediately.Go to Step 1 of "Problem 3".

The engine starts and the engine runs but engine shutdown occurs after the engine runs for more than 3 minutes.Go to Step 3.

The engine cranks but the engine does not start.Go to Step 1 of "Problem 1".

Check the start/stop switch.

Disconnect the wire in the junction box that connects terminal (SR1-85) of the slave relay (SR1) to terminal (TD-7) of the time delay relay (TD).

Disconnect the wire from terminal (TD-7) and insulate the exposed wire.

Crank the engine. Stop the engine with the emergency stop switch, if trouble occurs.Result

The engine starts and the engine runs.The start/stop switch has a short circuit or a wiring problem is causing a voltage at terminal (TD-7). Reconnect the wire to the terminal.

Check the start/stop switch.

Disconnect the wire that runs from the STOP position of terminal (SSS-6) to terminal (TD-6). Terminal (SSS-6) is on the start/stop switch.

Disconnect the wire at terminal (TD-7).

Crank the engine. Stop the engine with the emergency stop switch, if trouble occurs.Result

The engine starts and the engine runs.The start/stop switch is faulty. Replace the switch. STOP.

Engine shutdown still occurs.Reconnect the wire to terminal (TD-7). Go to Step 5

Check the slave relay (SR1).

Disconnect the wire that connects terminal (TS-10) of the junction box to terminal (TD-6) of the time delay relay.

Disconnect the wire at terminal (TD-6).

Crank the engine. Stop the engine with the emergency stop switch, if trouble occurs.Result

The engine starts and the engine runs.The start/stop switch is faulty. Replace the start/stop switch. STOP.

Engine shutdown still occurs.The contacts of SR1 periodically close. The problem may also be with the governor or the fuel supply to the engine. Refer to the Engine Service Manual. If a 2301A Electric Governor is used, the SR1 contacts may be opening. Refer to 2301A Electric Governor Service Manual, SENR3585. Test SR1. Refer to Testing and Adjusting, "Slave Relay Test".Problem 6

Engine shutdown does not occur