Information injection-pump assembly

BOSCH

9 400 616 152

9400616152

ZEXEL

101696-9570

1016969570

NISSAN-DIESEL

16713Z6408

16713z6408

Rating:

Include in #1:

106651-2472

as _

Cross reference number

BOSCH

9 400 616 152

9400616152

ZEXEL

101696-9570

1016969570

NISSAN-DIESEL

16713Z6408

16713z6408

Zexel num

Bosch num

Firm num

Name

101696-9570

9 400 616 152

16713Z6408 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FE6T K

FE6T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

14

Pump speed

r/min

550

550

550

Average injection quantity

mm3/st.

84.8

82.8

86.8

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

9.7+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

9.5

7.7

11.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(14)

Pump speed

r/min

550

550

550

Average injection quantity

mm3/st.

84.8

83.8

85.8

Basic

*

Fixing the lever

*

Boost pressure

kPa

25.3

25.3

Boost pressure

mmHg

190

190

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.1

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

91.9

88.7

95.1

Fixing the lever

*

Boost pressure

kPa

25.3

25.3

Boost pressure

mmHg

190

190

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.3

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

96.5

93.3

99.7

Fixing the lever

*

Boost pressure

kPa

25.3

25.3

Boost pressure

mmHg

190

190

Injection quantity adjustment_06

Adjusting point

D

Rack position

R2(12.3)

Pump speed

r/min

550

550

550

Average injection quantity

mm3/st.

59.7

58.7

60.7

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

83.5

83.5

103.5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

550

550

550

Rack position

R2(12.3)

Boost pressure

kPa

4

2.7

5.3

Boost pressure

mmHg

30

20

40

Boost compensator adjustment_02

Pump speed

r/min

550

550

550

Rack position

R1(14)

Boost pressure

kPa

12

12

12

Boost pressure

mmHg

90

90

90

Timer adjustment

Pump speed

r/min

1170--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1120

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

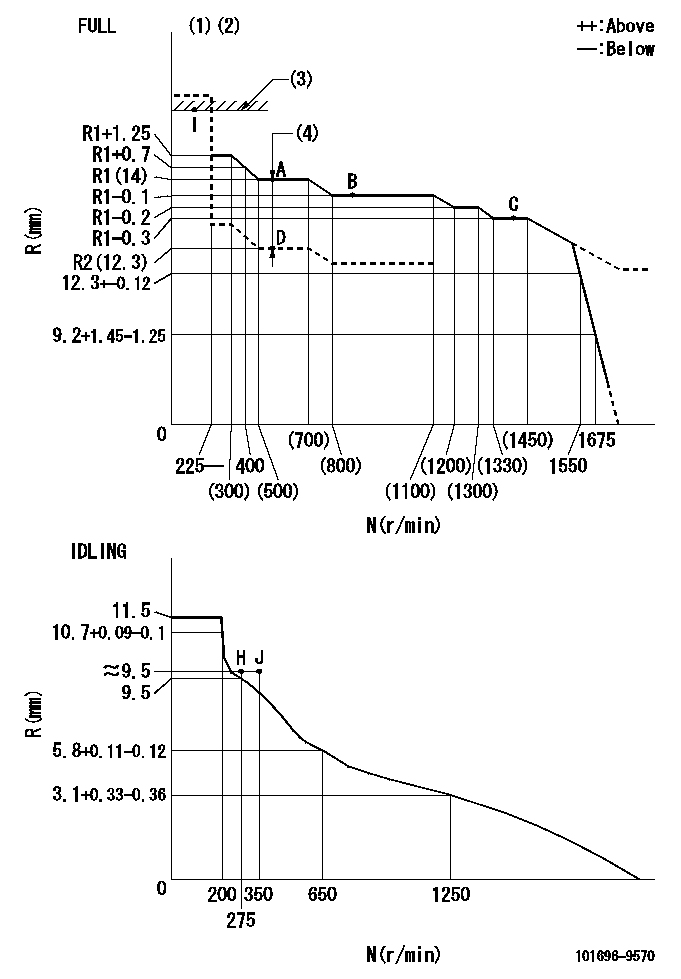

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

----------

T1=C44 BCL=(1.7)+-0.1mm

----------

----------

T1=C44 BCL=(1.7)+-0.1mm

----------

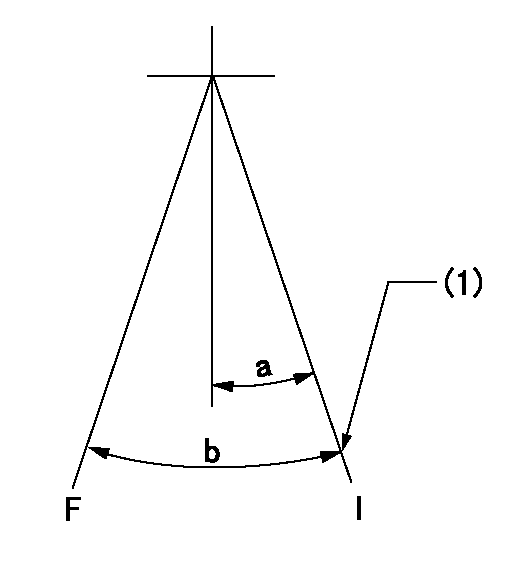

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=26.5deg+-5deg b=(42deg)+-3deg

----------

----------

a=26.5deg+-5deg b=(42deg)+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=20deg+-5deg b=40deg+-5deg

----------

----------

a=20deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Illustration 8 g00281837

Circuit breaker

(1) Reset button

(2) Disc in open position

(3) Contacts

(4) Disc in closed position

(5) Battery circuit terminals A circuit breaker is a switch that opens the circuit if the current in the electrical system is higher than the rating of the circuit breaker.A metal disc that is controlled with heat and a contact (3) will complete the circuit through the circuit breaker. If the current in the electrical system is too high, the metal disc becomes too hot. The heat causes a distortion of the metal disc which opens the contacts (2). Open contacts break the circuit. A circuit breaker that is open can be reset after the circuit breaker cools. Push the reset button (1) in order to close the contacts (4) and reset the circuit breaker.

Find and correct the problem that causes the circuit breaker to open.Correcting the problem before running the engine will help prevent damage to the circuit components caused by too much current.

Air Shutoff Solenoid (ASOS)

Illustration 9 g00281839

Air shutoff (Typical example)

(1) Air transfer pipe

(2) Valve assembly

(3) Shutoff shaft

(4) Governor control shaft

(5) Air shutoff solenoid

(6) O-ring seal

(7) Diode assembly

Illustration 10 g00293067

(5) Air shutoff solenoid that is mounted in the air intake pipe.

The air shutoff solenoid (5) is located in the air inlet system on the top of the engine. When the air shutoff solenoid ("ASOS") is energized, the inlet air to the engine is mechanically shut off. The ASOS can be energized in the following two ways:

The ASOS is energized by the overspeed switch (OS).

The ASOS is energized by the emergency stop switch (ES).Fuel Solenoid (FS)

Illustration 11 g00281970

Fuel solenoid (Typical example)

(1) Diode assembly

(2) Spring

(3) Governor drive

(4) Fuel solenoid

(5) Shaft

Illustration 12 g00293070

(4) Fuel solenoid (FS) that is mounted on the governor.

The fuel solenoid (FS) (4) is located on the governor or on the fuel injection pump of the engine. When the FS is energized, the spring (2) and the shaft (5) will cause the fuel rack to move directly or the fuel rack will move through the governor drive to the FUEL ON position. The FS must remain energized or the fuel flow will be stopped to the engine. 2301A Electric Governor Control

Illustration 13 g00293071

(1) 2301A Electric Governor Speed Control

Illustration 14 g00293069

Electric governor actuator (EGA) (2) and fuel solenoid (FS) (3). The components are mounted on the top of the engine.

The 2301A Electric Governor Control system consists of the following components:

2301A Control

Actuator (EGA)

Magnetic pickup (MPU)The 2301A Electric Governor Control system provides precision engine speed control. The 2301A Control constantly monitors the engine rpm. The control makes the necessary corrections to the engine fuel setting through an actuator that is connected to the fuel system.The engine rpm is measured by the magnetic pickup ("MU"). The magnetic pickup makes an AC voltage that is sent to the 2301A Control. The 2301A Control then sends a DC voltage signal to the actuator in order to adjust the fuel flow.The actuator changes the electrical signal from the 2301A Control to a mechanical output. The mechanical output of the actuator causes the linkage from the actuator

Have questions with 101696-9570?

Group cross 101696-9570 ZEXEL

Nissan-Diesel

Nissan-Diesel

101696-9570

9 400 616 152

16713Z6408

INJECTION-PUMP ASSEMBLY

FE6T

FE6T