Information injection-pump assembly

BOSCH

9 400 610 802

9400610802

ZEXEL

101696-9431

1016969431

NISSAN-DIESEL

16713Z6466

16713z6466

Rating:

Service parts 101696-9431 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-Z5578

12.

Open Pre:MPa(Kqf/cm2)

16.7{170}/21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 610 802

9400610802

ZEXEL

101696-9431

1016969431

NISSAN-DIESEL

16713Z6466

16713z6466

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-1520

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

13.2

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

103

101

105

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

8.6

6.8

10.4

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.2)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

103

102

104

Basic

*

Fixing the lever

*

Boost pressure

kPa

26.7

26.7

Boost pressure

mmHg

200

200

Injection quantity adjustment_04

Adjusting point

B

Rack position

(R1+0.2)

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

111.5

108.3

114.7

Fixing the lever

*

Boost pressure

kPa

26.7

26.7

Boost pressure

mmHg

200

200

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2(R1+0.

1)

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

85.5

82.3

88.7

Fixing the lever

*

Boost pressure

kPa

26.7

26.7

Boost pressure

mmHg

200

200

Injection quantity adjustment_06

Adjusting point

D

Rack position

R2-1.3

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

61.5

58.3

64.7

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

89

89

109

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

250

250

250

Rack position

R2-1.3

Boost pressure

kPa

4

2.7

5.3

Boost pressure

mmHg

30

20

40

Boost compensator adjustment_02

Pump speed

r/min

250

250

250

Rack position

R2(R1+0.

1)

Boost pressure

kPa

13.3

13.3

13.3

Boost pressure

mmHg

100

100

100

Timer adjustment

Pump speed

r/min

1170--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

450

Advance angle

deg.

1

0.5

1.5

Timer adjustment_03

Pump speed

r/min

(530)

Advance angle

deg.

0

0

0

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

1120

Advance angle

deg.

0.5

Timer adjustment_05

Pump speed

r/min

1400

Advance angle

deg.

4.5

4

5

Remarks

Finish

Finish

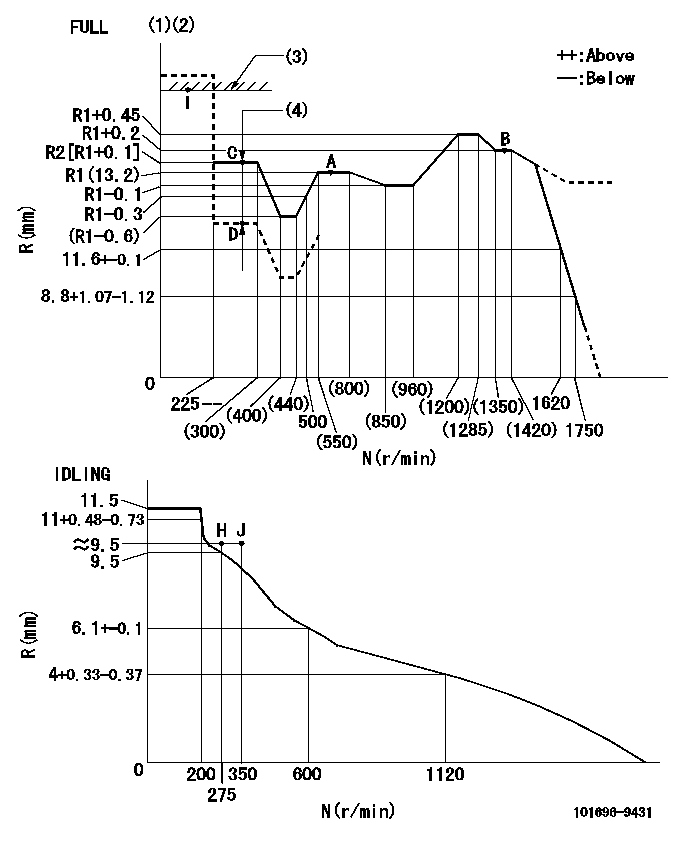

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

----------

T1=K21 BCL=1.3+-0.1mm

----------

----------

T1=K21 BCL=1.3+-0.1mm

----------

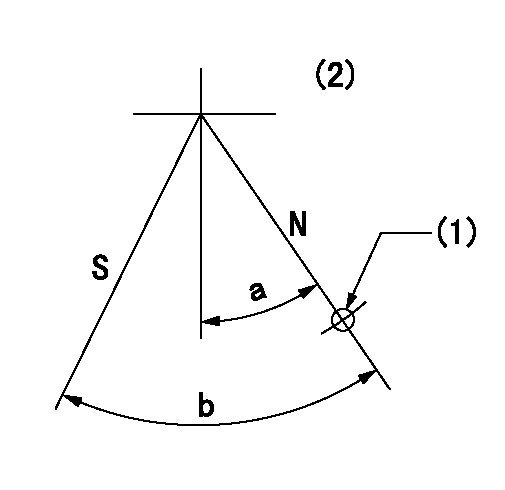

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=36mm

----------

a=25deg+-5deg b=39deg+-3deg

----------

aa=36mm

----------

a=25deg+-5deg b=39deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)No return spring

----------

aa=28mm

----------

a=20deg+-5deg b=40deg+-5deg

----------

aa=28mm

----------

a=20deg+-5deg b=40deg+-5deg

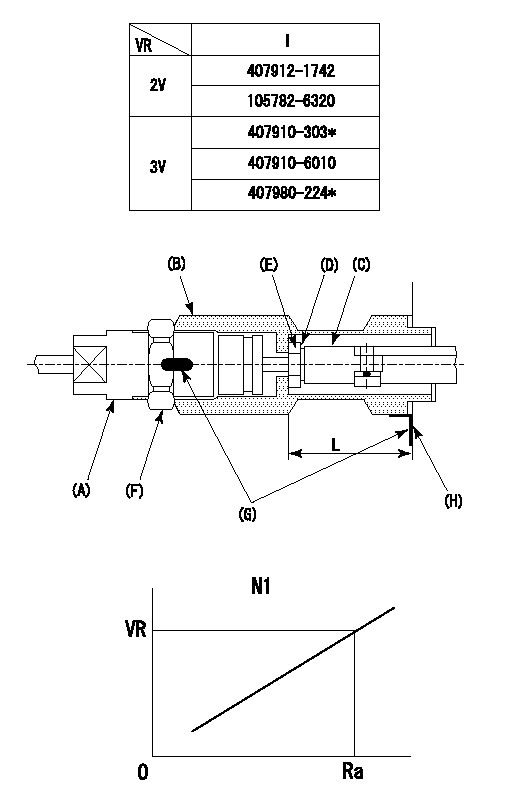

0000001501 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack limit adjustment

(1)Fix the rack at the rack limit position Ra.

(2)Install the shim (D) to the rod (C) and tighten nut (E).

(3)Select a shim (D) so that the distance between the end surface of the pump and the nut (E) is L.

(4)Release the rack fixing and mount the joint (B) and fix.

(5)At this time, confirm that the shim (D) does not interfere with the joint (B).

2. Rack sensor adjustment (-0420)

(1)Screw in the bobbin (A) until it contacts the joint (B).

(2)Fix the speed control lever at the full side.

(3)Set the speed to N1 r/min.

(4)Adjust the depth that the bobbin (A) is screwed in so that the control unit's rack sensor output voltage is VR+-0.02 V, then tighten the nut (F).

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

L=33-0.2mm N1=700r/min Ra=R1(13.2)mm

----------

----------

L=33-0.2mm N1=700r/min Ra=R1(13.2)mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

AFFECTED PRODUCT

Model Identification Number

C9 LFE00178-00180, 182, 193-194, 196, 2025, 2372-2375, 2585-2588, 2594-2595, 2710, 2714-2716, 2718-2722, 2725-2727, 2729, 2731-2741, 2743-2747, 2765-2784, 2831, 2833-2836, 2838-2839, 2841-2843, 2847-2852, 2855, 2857-2858, 2862, 2879, 2881-2886, 2888, 2890-2892, 2894-2896, 2898-2907, 2909, 2914, 2916-2918, 2920-2921, 2923-2924, 2926, 2928, 2931, 2934, 2937, 2986, 2988-2993, 2995-3043, 3045-3065, 3101-3106, 3110-3111, 3113, 3116, 3118, 3120, 3122, 3125, 3127-3129, 3132-3133, 3138, 3149-3168, 3204-3242, 3250, 3258-3343, 3345-3386, 3582-3584, 3590-3604, 3681-3730, 3732-3735, 3738-3739, 3741-3742, 3744-3749, 3791, 3793-3794, 3812-3831, 3866-3880, 3882-3897, 3899-3919, 3950-4020, 4026-4083, 4085-4118, 4121-4122, 4124-4151, 4153-4240, 4242, 4253-4278, 4281-4316, 4383-4384, 4387-4390, 4392-4395, 4398-4492, 4495-4497

PARTS NEEDED

Qty

Part Number Description

1 5734235 INJECTOR GP

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 1% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

****Parts Stock ****

Remove all 387-9435 Fuel Injectors from dealer parts stock. Refer to the Parts Disposition.

****Affected Product****

Replace the failed 387-9435 Fuel Injector with a 573-4235 Fuel Injector. Refer to the Disassembly and Assembly, RENR7460, "Unit Injector - Remove", and "Unit Injector - Install", for rework instructions.

SERVICE CLAIM ALLOWANCES

****Parts Stock****

Submit one claim for all parts removed from dealer parts stock.

****Affected Product****

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-6000 hrs,

0-192 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 3.0-hour job

PARTS DISPOSITION

****Parts Stock****

Hold all 387-9435 Fuel Injectors for a Parts Return Request (PRR). A Parts Return Request (PRR) will be issued to you through the Send-It-Back process after the claim is submitted. Make sure to list the service letter program number on the packing slip and include the closed work order paperwork. Handle all other parts in accordance with your Warranty Bulletin on warranty parts handling.

If a Parts Return Request (PRR) is not issued to you after 30 days through the Send-It-Back process, handle the parts in accordance with your warranty bulletin on warranty parts handling.

****Affected Product****

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.