Information injection-pump assembly

BOSCH

9 400 616 136

9400616136

ZEXEL

101696-9090

1016969090

NISSAN-DIESEL

1671395210

1671395210

Rating:

Service parts 101696-9090 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1660095015

12.

Open Pre:MPa(Kqf/cm2)

19.6(200)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 616 136

9400616136

ZEXEL

101696-9090

1016969090

NISSAN-DIESEL

1671395210

1671395210

Zexel num

Bosch num

Firm num

Name

101696-9090

9 400 616 136

1671395210 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

NE6T * K 14BF INJECTION PUMP ASSY PE6AD PE

NE6T * K 14BF INJECTION PUMP ASSY PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.7

3.65

3.75

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.6

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

95.5

93.9

97.1

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

8

6.2

9.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.6)

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

95.5

94.5

96.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.1

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

85

81.8

88.2

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1+0.1

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

66.5

63.3

69.7

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

85

85

105

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

920--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

870

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

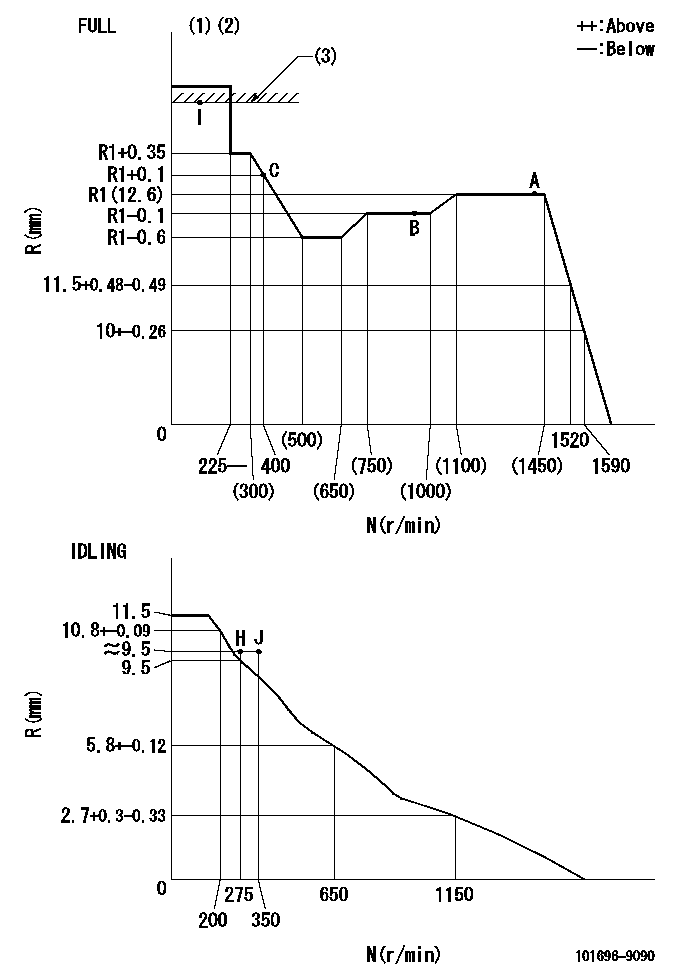

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=M64

----------

----------

T1=M64

----------

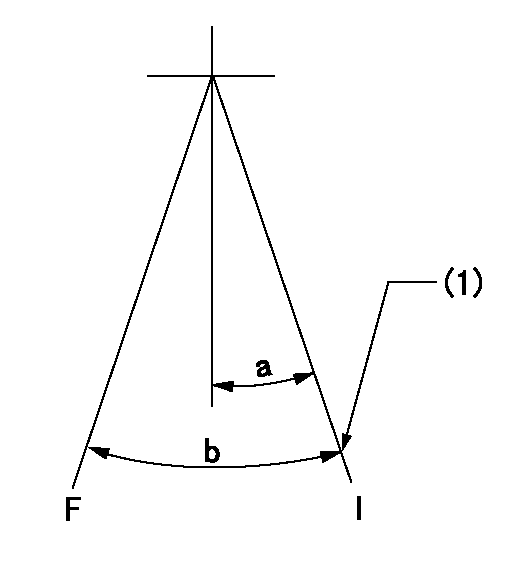

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=26.5deg+-5deg b=(43deg)+-3deg

----------

----------

a=26.5deg+-5deg b=(43deg)+-3deg

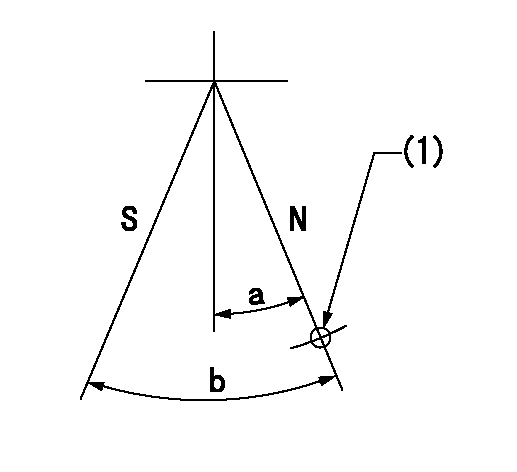

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

----------

aa=36mm

----------

a=20deg+-5deg b=40deg+-5deg

----------

aa=36mm

----------

a=20deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Temporary corrections to the charts in this book will be printed in the publication ENGINE NEWS. Announcement for revised reprints of this book will be made in PREVIEW.These instructions are intended to acquaint you with the content of the rack setting charts. A description is given of the information to be found under each column heading. Read these instructions carefully so you can better understand the information presented.After reading and understanding these instructions, use the following suggestions to aid in the actual use of the rack setting charts.1. Determine and write down the engine model and engine serial number.2. Locate the correct rack setting chart.3. Locate the correct segment of the chart being used. Particular attention must be focused on the model and serial number.4. Read all notes pertaining to the engine being repaired. The notes are just as important as any other information that is presented on the rack setting chart.Column Headings

Column headings and arrangement of material can vary from chart to chart according to data requirements for the engines. A brief description of each column heading, note and symbol follows. See Fig. 1.Model

The MODEL column lists the description of the engine, and the serial number range to which the data applies. Be sure to use the data from the correct serial number range for the engine being repaired.Engine Full Load RPM

The column lists the engine speed (under load) at which the rack is positioned to permit maximum allowable amount of fuel to the engine per unit of time. Turbocharger speed, inlet manifold pressure and horsepower output are at their maximum for the listed rack setting. A tolerance of 10 RPM is allowed.Engine High Idle RPM

This column lists the high idle speed of the bare engine when driving a dynamometer. Use the figures in the chart when adjusting high idle in the truck. A tolerance of 30 RPM is allowed in most applications.Brake Horsepower

This column lists the power available at the flywheel, without fan, and within the limitations indicated in the charts. A tolerance of 3% of this value is normal from a new or reconditioned engine.

Fig. 1Rack Setting

The rack setting is the distance the rack must travel from the centered (sometimes referred to as zero) position, to supply sufficient fuel, to produce the expected power output of the engine. Rack setting is controlled by a stop bar or torque spring that is located within the governor. The stop bar and/or torque spring limits the maximum travel of the fuel rack. Rack setting procedure is explained and illustrated in the TESTING AND ADJUSTING Section of the applicable service manual.All rack settings are plus (+) settings unless otherwise indicated with a minus (-) sign. See Fig. 2.Torque Spring And Spacer

This column lists the part number and thickness of the torque spring, and only those spacers or shims installed between the torque spring and stop. Any shims located behind the stop are not listed. The dimensions are in inches and are for means of identification.

Fig.

Column headings and arrangement of material can vary from chart to chart according to data requirements for the engines. A brief description of each column heading, note and symbol follows. See Fig. 1.Model

The MODEL column lists the description of the engine, and the serial number range to which the data applies. Be sure to use the data from the correct serial number range for the engine being repaired.Engine Full Load RPM

The column lists the engine speed (under load) at which the rack is positioned to permit maximum allowable amount of fuel to the engine per unit of time. Turbocharger speed, inlet manifold pressure and horsepower output are at their maximum for the listed rack setting. A tolerance of 10 RPM is allowed.Engine High Idle RPM

This column lists the high idle speed of the bare engine when driving a dynamometer. Use the figures in the chart when adjusting high idle in the truck. A tolerance of 30 RPM is allowed in most applications.Brake Horsepower

This column lists the power available at the flywheel, without fan, and within the limitations indicated in the charts. A tolerance of 3% of this value is normal from a new or reconditioned engine.

Fig. 1Rack Setting

The rack setting is the distance the rack must travel from the centered (sometimes referred to as zero) position, to supply sufficient fuel, to produce the expected power output of the engine. Rack setting is controlled by a stop bar or torque spring that is located within the governor. The stop bar and/or torque spring limits the maximum travel of the fuel rack. Rack setting procedure is explained and illustrated in the TESTING AND ADJUSTING Section of the applicable service manual.All rack settings are plus (+) settings unless otherwise indicated with a minus (-) sign. See Fig. 2.Torque Spring And Spacer

This column lists the part number and thickness of the torque spring, and only those spacers or shims installed between the torque spring and stop. Any shims located behind the stop are not listed. The dimensions are in inches and are for means of identification.

Fig.

Have questions with 101696-9090?

Group cross 101696-9090 ZEXEL

Nissan-Diesel

Nissan-Diesel

101696-9090

9 400 616 136

1671395210

INJECTION-PUMP ASSEMBLY

NE6T

NE6T