Information injection-pump assembly

BOSCH

9 400 610 306

9400610306

ZEXEL

101696-9020

1016969020

Rating:

Service parts 101696-9020 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-Z5570

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 610 306

9400610306

ZEXEL

101696-9020

1016969020

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.5

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

83.7

82.1

85.3

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

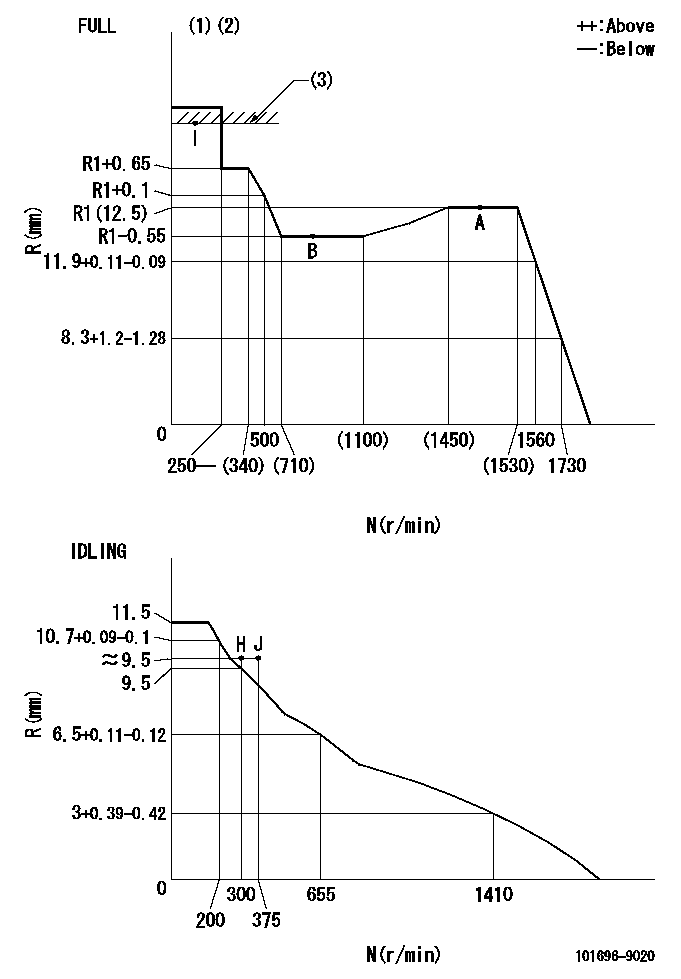

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

9.5

7.7

11.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.5)

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

83.7

82.7

84.7

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.55

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

68.7

66.7

70.7

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

85

85

105

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1050--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=C35

----------

----------

T1=C35

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=100mm

----------

a=26.5deg+-5deg b=(37deg)+-3deg

----------

aa=100mm

----------

a=26.5deg+-5deg b=(37deg)+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=20deg+-5deg b=40deg+-5deg

----------

----------

a=20deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

If the vehicle has a disconnect switch, the starting circuit can operate only after the disconnect switch is put in the ON position.The starting circuit is in operation only when the start switch is activated.The low amperage circuit and the charging circuit are both connected to the same side of the ammeter. The starting circuit connects to the opposite side of the ammeter.

Never operate the alternator without the battery in the circuit. Making or breaking an alternator connection with heavy load on the circuit can cause damage to the regulator.

Charging System Components

Alternator

Alternator Components (Typical Example)

(1) Brush holder. (2) Rear frame. (3) Rotor. (4) Stator. (5) Drive end frame. (6) Fan assembly. (7) Slip rings. (8) Rectifier.The alternator has three phase, full-wave, rectified output. It is a brush type alternator.The alternator is an electrical and mechanical component driven by a belt from engine rotation. It is used to charge the storage battery during engine operation. The alternator is cooled by a fan that is a part of the alternator. The fan pulls air through holes in the back of the alternator. The air exits the front of the alternator, cooling it in the process.The alternator converts mechanical and magnetic energy to alternating current (AC) and voltage. This process is done by rotating a direct current (DC) electromagnetic field (rotor) inside a three phase stator. The alternating current and voltage (generated by the stator) are changed to direct current by a three phase, full wave rectifier system using six silicone rectifier diodes. The alternator also has a diode trio which is an assembly made up of three exciter diodes. The diode trio rectifies field current needed to start the charging process. Direct current flows to the alternator output terminal.A solid state regulator is installed in the back of the alternator. Two brushes conduct current, through two slip rings, to the field coil on the rotor.There is also a capacitor mounted in the back of the alternator. The capacitor protects the rectifier from high voltages. It also suppresses radio noise.Regulator

The voltage regulator is a solid state (transistor, stationary parts) electronic switch which controls the alternator output. The regulator limits the alternator voltage to a preset value by controlling the field current. It feels the voltage in the system and switches "ON" and "OFF" many times a second to control the field current (DC current to the field windings) for the alternator to make the needed voltage output. Refer to Service Manual, SENR3862, for detailed service information for the Delco Remy 27 SI Series Alternator. For engines which have the alternator connected to an engine component, the ground strap must connect that component to the frame or to the battery ground.Starting System Components

Starter Solenoid

A solenoid is a magnetic switch that does two basic operations:1. Closes the high current starter motor circuit with a low current start switch circuit.2. Engages the starter motor pinion with the ring gear.

Typical SolenoidThe solenoid switch is made of an electromagnet (one or two sets of windings) around

Never operate the alternator without the battery in the circuit. Making or breaking an alternator connection with heavy load on the circuit can cause damage to the regulator.

Charging System Components

Alternator

Alternator Components (Typical Example)

(1) Brush holder. (2) Rear frame. (3) Rotor. (4) Stator. (5) Drive end frame. (6) Fan assembly. (7) Slip rings. (8) Rectifier.The alternator has three phase, full-wave, rectified output. It is a brush type alternator.The alternator is an electrical and mechanical component driven by a belt from engine rotation. It is used to charge the storage battery during engine operation. The alternator is cooled by a fan that is a part of the alternator. The fan pulls air through holes in the back of the alternator. The air exits the front of the alternator, cooling it in the process.The alternator converts mechanical and magnetic energy to alternating current (AC) and voltage. This process is done by rotating a direct current (DC) electromagnetic field (rotor) inside a three phase stator. The alternating current and voltage (generated by the stator) are changed to direct current by a three phase, full wave rectifier system using six silicone rectifier diodes. The alternator also has a diode trio which is an assembly made up of three exciter diodes. The diode trio rectifies field current needed to start the charging process. Direct current flows to the alternator output terminal.A solid state regulator is installed in the back of the alternator. Two brushes conduct current, through two slip rings, to the field coil on the rotor.There is also a capacitor mounted in the back of the alternator. The capacitor protects the rectifier from high voltages. It also suppresses radio noise.Regulator

The voltage regulator is a solid state (transistor, stationary parts) electronic switch which controls the alternator output. The regulator limits the alternator voltage to a preset value by controlling the field current. It feels the voltage in the system and switches "ON" and "OFF" many times a second to control the field current (DC current to the field windings) for the alternator to make the needed voltage output. Refer to Service Manual, SENR3862, for detailed service information for the Delco Remy 27 SI Series Alternator. For engines which have the alternator connected to an engine component, the ground strap must connect that component to the frame or to the battery ground.Starting System Components

Starter Solenoid

A solenoid is a magnetic switch that does two basic operations:1. Closes the high current starter motor circuit with a low current start switch circuit.2. Engages the starter motor pinion with the ring gear.

Typical SolenoidThe solenoid switch is made of an electromagnet (one or two sets of windings) around