Information injection-pump assembly

BOSCH

9 400 616 131

9400616131

ZEXEL

101695-3811

1016953811

KOMATSU

6207711520

6207711520

Rating:

Service parts 101695-3811 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6207-11-3600

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 616 131

9400616131

ZEXEL

101695-3811

1016953811

KOMATSU

6207711520

6207711520

Zexel num

Bosch num

Firm num

Name

101695-3811

9 400 616 131

6207711520 KOMATSU

INJECTION-PUMP ASSEMBLY

S6D95L K 14BE INJECTION PUMP ASSY PE6A PE

S6D95L K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

12

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

65

64

66

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

36

36

Boost pressure

mmHg

270

270

Injection quantity adjustment_02

Adjusting point

-

Rack position

10.4+-0.

5

Pump speed

r/min

385

385

385

Average injection quantity

mm3/st.

12.5

11.5

13.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Boost compensator adjustment

Pump speed

r/min

550

550

550

Rack position

11.1

Boost pressure

kPa

6.7

4

9.4

Boost pressure

mmHg

50

30

70

Boost compensator adjustment_02

Pump speed

r/min

550

550

550

Rack position

12.3

Boost pressure

kPa

22.7

16

29.4

Boost pressure

mmHg

170

120

220

Test data Ex:

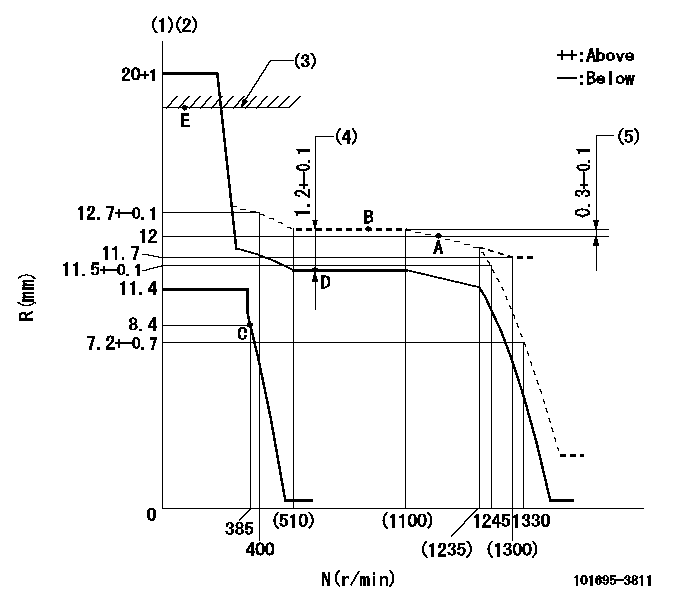

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT: RAL

(4)Boost compensator stroke

(5)Rack difference between N = N1 and N = N2

----------

K=9 RAL=15+0.2mm N1=1200r/min N2=800r/min

----------

----------

K=9 RAL=15+0.2mm N1=1200r/min N2=800r/min

----------

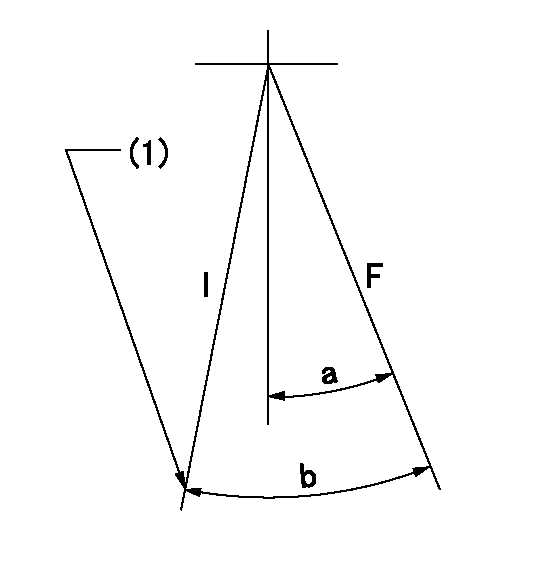

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=12deg+-5deg b=27deg+-5deg

----------

----------

a=12deg+-5deg b=27deg+-5deg

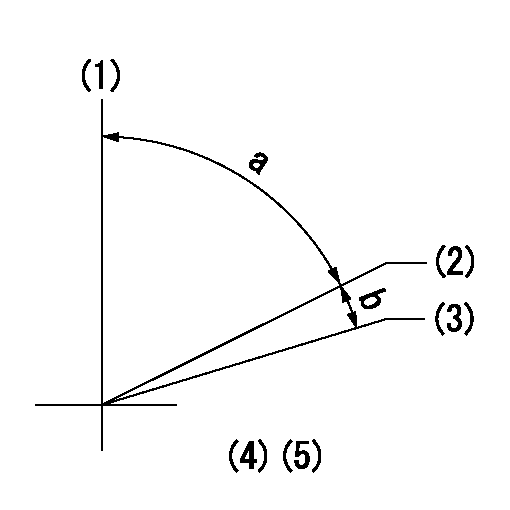

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of key groove at No 1 cylinder's beginning of injection

(3)Stamp aligning marks on the pump housing flange.

(4)-

----------

----------

a=59deg36min+-3deg b=0deg24min+-30min

----------

----------

a=59deg36min+-3deg b=0deg24min+-30min

Information:

Guidelines For Reusable Parts; Valves And Valve Springs, SEBF8002 and SEBF8034 have the procedure and specifications necessary for checking used valves and valve springs.(1) 4W2471 Spring for valves (outer) (new): Length under test force ... 53.24 mm (2.096 in)Test force ... 245 24 N (55 5 lb)Use again minimum load at length under test force ... 211 N (48 lb)Length of spring at valve open position ... 39.0 mm (1.54 in)Use again minimum load at valve open position ... 755 N (170 lb)Free length after test ... 59.5 mm (2.34 in)Outside diameter ... 37.31 mm (1.469 in)Spring must not be bent more than ... 2.10 mm (.083 in)(1) 4W2472 Spring for valves (inner) (new): Length under test force ... 50.24 mm (1.978 in)Test force ... 178 18 N (40 4 lb)Use again minimum load at length under test force ... 155 N (35 lb)Length of spring at valve open position ... 36.0 mm (1.42 in)Use again minimum load at valve open position ... 321 N (72 lb)Free length after test ... 65.7 mm (2.60 in)Outside diameter ... 25.13 mm (.989 in)Spring must not be bent more than ... 2.30 mm (.091 in)(2) Height to top of valve guide ... 27.2 .8 mm (1.07 .03 in)(3) Diameter of valve stem (new) ... 9.441 .01 mm (.3717 .0004 in)Use again minimum diameter of valve stems:Exhaust ... 9.408 mm (.3704 in)Inlet ... 9.408 mm (.3704 in)Bore in valve guide with guide installed in the head (new) ... 9.487 0.025 mm (.3735 .0010 in)Use again dimension for valve guide bore ... 9.538 mm (.3755 in)(4) Diameter of valve head: Exhaust valve ... 41.81 0.13 mm (1.646 .005 in)Inlet valve ... 44.98 0.13 mm (1.771 .005 in)(5) Angle of inlet valve face ... 29 1/4 1/4 degreesAngle of exhaust valve face ... 44 1/4 1/4 degrees (6) Depth of bore in head for valve seat insert ... 13.01 0.35 mm (.512 .014 in)(7) Diameter of valve seat insert for inlet valve ... 46.025 0.013 mm (1.8120 .0005 in) Bore in head for valve seat insert for inlet valve ... 45.949 0.025 mm (1.8090 .0010 in)Diameter of valve seat insert for exhaust valve ... 42.850 0.013 mm (1.6870 .0005 in)Bore in head for valve seat insert for exhaust valve ... 42.774 0.025 mm (1.6840 .0010 in)(8) Angle of face of inlet valve seat insert ... 30 1/4 1/2 degreesAngle of face of exhaust valve seat insert ... 44 3/4 1/2 degrees(9) Dimension from end of closed valve to machined face of head. Maximum permissible dimension:Below (recessed from) machined face ... 1.22 mm (.048 in)Above (extended from) machined face ... 0.20

Have questions with 101695-3811?

Group cross 101695-3811 ZEXEL

Komatsu

Komatsu

101695-3811

9 400 616 131

6207711520

INJECTION-PUMP ASSEMBLY

S6D95L

S6D95L