Information injection-pump assembly

ZEXEL

101695-3810

1016953810

Rating:

Cross reference number

ZEXEL

101695-3810

1016953810

Zexel num

Bosch num

Firm num

Name

101695-3810

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

R1(11.9)

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

62

61

63

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

34.7

34.7

Boost pressure

mmHg

260

260

Injection quantity adjustment_02

Adjusting point

-

Rack position

9.7+-0.5

Pump speed

r/min

385

385

385

Average injection quantity

mm3/st.

8

7

9

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

E

Rack position

15+0.2

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

63

53

73

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1-1

Boost pressure

kPa

8.7

6

11.4

Boost pressure

mmHg

65

45

85

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R1(11.9)

Boost pressure

kPa

21.3

14.6

28

Boost pressure

mmHg

160

110

210

Test data Ex:

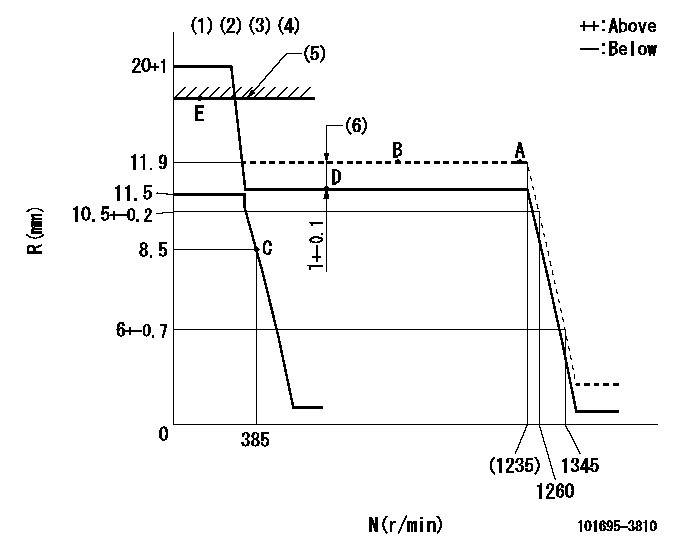

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)The torque control spring does not operate.

(4)Idle spring not operating.

(5)RACK LIMIT: RAL

(6)Boost compensator stroke

----------

K=7 RAL=15+0.2mm

----------

----------

K=7 RAL=15+0.2mm

----------

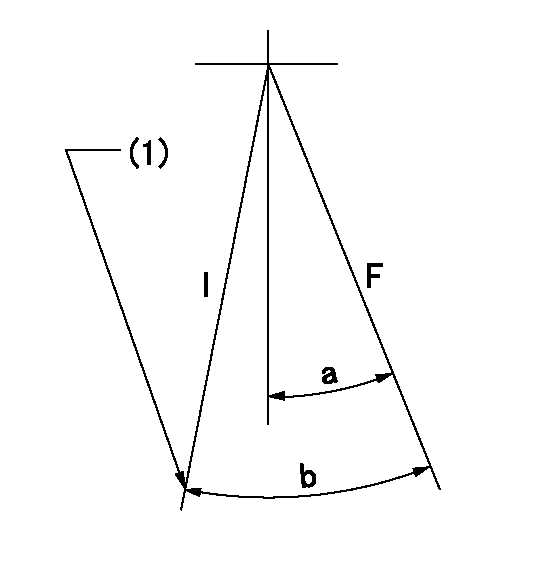

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=11deg+-5deg b=27deg+-5deg

----------

----------

a=11deg+-5deg b=27deg+-5deg

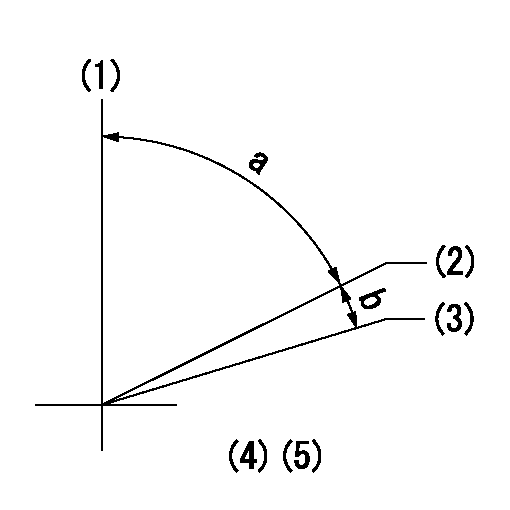

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of key groove at No 1 cylinder's beginning of injection

(3)Stamp aligning marks on the pump housing flange.

(4)-

(5)-

----------

----------

a=59deg36min+-3deg b=0deg24min+-30min

----------

----------

a=59deg36min+-3deg b=0deg24min+-30min

Information:

(1) Gear. If new gear is required, replace camshaft assembly. The heat treatment of the gear is damaged if heated.(2) Diameter of the surfaces (journals) for the camshaft bearings (new) ... 69.850 0.013 mm (2.7500 .0005 in) Bore in front bearing for the camshaft (after assembly) ... 69.969 0.048 mm (2.7547 .0019 in)Bore in the other six bearings for the camshaft (after assembly) ... 69.982 0.061 mm (2.7552 .0024 in)(3) Thickness of thrust plate (new) ... 4.65 0.03 mm (.183 .001 in) End play of the camshaft ... 0.10 to 0.26 mm (.004 to .010 in)(4) Camshaft. (5) Height of camshaft lobes.To find lobe height, use the procedure that follows:A. Measure camshaft lobe height (5).B. Measure base circle (7).C. Subtract base circle (STEP B) from lobe height (STEP A). The difference is actual lobe lift (6).D. Specified camshaft lobe lift (6) is: Camshaft Assemblya. Exhaust lobe ... 10.5 mm (.413 in)b. Inlet lobe ... 10.5 mm (.413 in)Maximum permissible difference between actual lobe lift (STEP C) and specified lobe lift (STEP D) is 0.13 mm (.005 in)Inlet Valve Timing

1. Check the No. 1 inlet valve lash with the engine stopped. The valve lash must be 0.30 to 0.46 mm (.012 to .018 in). If the valve lash is not in this range, adjust the lash to 0.38 mm (.015 in).2. Mark Top Center Position of the crankshaft on the vibration damper or pulley.3. Use a dial indicator to measure the inlet valve movement.4. Rotate the crankshaft in the direction of normal engine rotation. Stop when the inlet valve is 1.91 mm (.075 in) off its seat in the opening sequence.At this point the crankshaft Top Center Position Mark must be ... 5 2 degrees After Top CenterChecking Valve-Camshaft Timing (field procedure)

The following procedure will simplify the checking of the camshaft timing procedures.1. Set the No. 3 inlet bridge adjustment. Refer to SENR6547 (Testing And Adjusting).2. Set the No. 3 inlet valve lash. Refer to SENR6547 (Testing And Adjusting).3. Install the bolt in the flywheel with No. 1 piston at top center.4. Install the dial indicator (magnetic base) to No. 3 inlet bridge.5. Remove the bolt from the flywheel.6. Set the indicator at zero and rotate the engine in the normal direction of operation (counterclockwise as viewed from the flywheel end) until dial travel stops.The correct setting should be ... 14.21 0.25 mm (.560 .010 in)

1. Check the No. 1 inlet valve lash with the engine stopped. The valve lash must be 0.30 to 0.46 mm (.012 to .018 in). If the valve lash is not in this range, adjust the lash to 0.38 mm (.015 in).2. Mark Top Center Position of the crankshaft on the vibration damper or pulley.3. Use a dial indicator to measure the inlet valve movement.4. Rotate the crankshaft in the direction of normal engine rotation. Stop when the inlet valve is 1.91 mm (.075 in) off its seat in the opening sequence.At this point the crankshaft Top Center Position Mark must be ... 5 2 degrees After Top CenterChecking Valve-Camshaft Timing (field procedure)

The following procedure will simplify the checking of the camshaft timing procedures.1. Set the No. 3 inlet bridge adjustment. Refer to SENR6547 (Testing And Adjusting).2. Set the No. 3 inlet valve lash. Refer to SENR6547 (Testing And Adjusting).3. Install the bolt in the flywheel with No. 1 piston at top center.4. Install the dial indicator (magnetic base) to No. 3 inlet bridge.5. Remove the bolt from the flywheel.6. Set the indicator at zero and rotate the engine in the normal direction of operation (counterclockwise as viewed from the flywheel end) until dial travel stops.The correct setting should be ... 14.21 0.25 mm (.560 .010 in)

Have questions with 101695-3810?

Group cross 101695-3810 ZEXEL

Komatsu

101695-3810

INJECTION-PUMP ASSEMBLY