Information injection-pump assembly

ZEXEL

101695-3540

1016953540

KOMATSU

6206711261

6206711261

Rating:

Cross reference number

ZEXEL

101695-3540

1016953540

KOMATSU

6206711261

6206711261

Zexel num

Bosch num

Firm num

Name

101695-3540

6206711261 KOMATSU

INJECTION-PUMP ASSEMBLY

6D95L * K

6D95L * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.3

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

36.5

35.5

37.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

10.5+-0.

5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

10.5

9.5

11.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

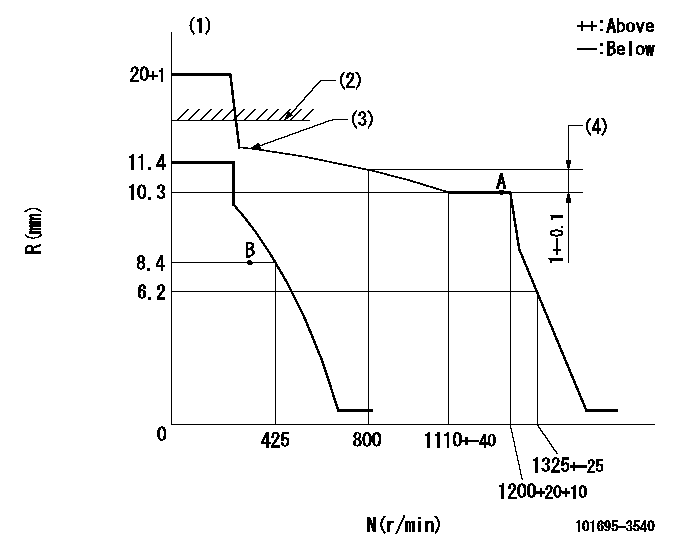

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)The torque control spring must does not have a set force.

(4)Rack difference between N = N1 and N = N2

----------

K=15 RAL=15+0.2mm N1=1200r/min N2=800r/min

----------

----------

K=15 RAL=15+0.2mm N1=1200r/min N2=800r/min

----------

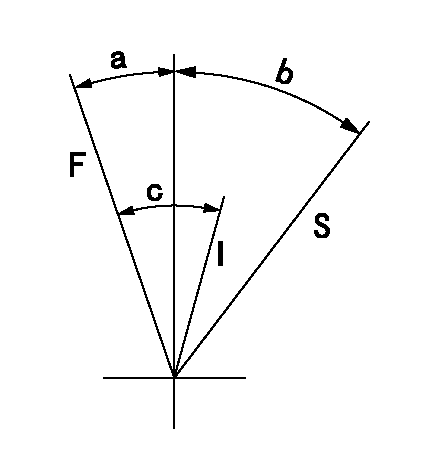

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=20deg+-5deg b=32deg+-3deg c=26deg+-5deg

----------

----------

a=20deg+-5deg b=32deg+-3deg c=26deg+-5deg

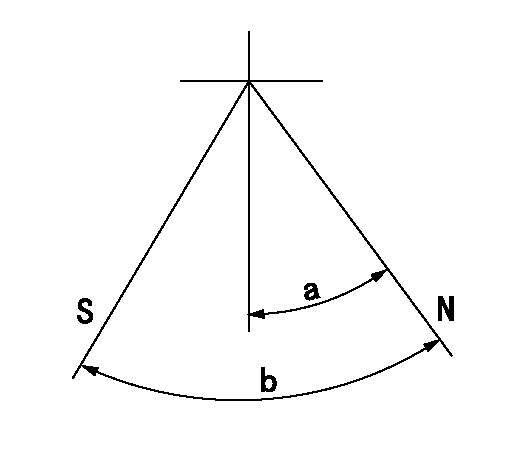

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=28deg+-5deg b=53deg+-5deg

----------

----------

a=28deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Start Bya. remove flywheel

Do not damage the flange on the crankshaft when the crankshaft rear seal is removed. Use of any other tool, other than Tool (A), to remove the crankshaft rear seal, can result in damage to the crankshaft.

1. Carefully make three evenly spaced holes in the crankshaft rear seal with a hammer and sharp punch. Use Tool (A) to remove crankshaft rear seal (1). Do not damage the flange of the crankshaft during seal removal. The following steps are for the installation of the crankshaft rear seal.2. Be sure the flange of the crankshaft is thoroughly clean prior to seal installation. 3. Fasten the 1U7595 Locator Assembly [part of Tool (B)] to the rear of the crankshaft as shown.4. Leaving the seal shipping sleeve in position on the new crankshaft rear seal, position the new seal over the locator assembly. The 1U7597 Sleeve Ring [part of Tool (B)] is not used in this in the seal installation.5. Install the 1U7594 Installer [part of Tool (B)] on the locator assembly. Tighten the nut assembly of Tool (B) to push the crankshaft rear seal into position on the flange of the crankshaft. Remove Tool (B) and the shipping sleeve. The distance between the front face of the crankshaft rear seal and the rear face of the cylinder block must be 15.4 0.5 mm (.61 .02 in) after seal installation. See the topic "Crankshaft Seals" in the 3114 & 3116 Diesel Truck Engines Specifications module, Form No. SENR6436 for further details.End By:a. install flywheel

Do not damage the flange on the crankshaft when the crankshaft rear seal is removed. Use of any other tool, other than Tool (A), to remove the crankshaft rear seal, can result in damage to the crankshaft.

1. Carefully make three evenly spaced holes in the crankshaft rear seal with a hammer and sharp punch. Use Tool (A) to remove crankshaft rear seal (1). Do not damage the flange of the crankshaft during seal removal. The following steps are for the installation of the crankshaft rear seal.2. Be sure the flange of the crankshaft is thoroughly clean prior to seal installation. 3. Fasten the 1U7595 Locator Assembly [part of Tool (B)] to the rear of the crankshaft as shown.4. Leaving the seal shipping sleeve in position on the new crankshaft rear seal, position the new seal over the locator assembly. The 1U7597 Sleeve Ring [part of Tool (B)] is not used in this in the seal installation.5. Install the 1U7594 Installer [part of Tool (B)] on the locator assembly. Tighten the nut assembly of Tool (B) to push the crankshaft rear seal into position on the flange of the crankshaft. Remove Tool (B) and the shipping sleeve. The distance between the front face of the crankshaft rear seal and the rear face of the cylinder block must be 15.4 0.5 mm (.61 .02 in) after seal installation. See the topic "Crankshaft Seals" in the 3114 & 3116 Diesel Truck Engines Specifications module, Form No. SENR6436 for further details.End By:a. install flywheel

Have questions with 101695-3540?

Group cross 101695-3540 ZEXEL

Komatsu

101695-3540

6206711261

INJECTION-PUMP ASSEMBLY

6D95L

6D95L