Information injection-pump assembly

ZEXEL

101693-9110

1016939110

NISSAN-DIESEL

1670095074

1670095074

Rating:

Cross reference number

ZEXEL

101693-9110

1016939110

NISSAN-DIESEL

1670095074

1670095074

Zexel num

Bosch num

Firm num

Name

101693-9110

1670095074 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

ND6 * K

ND6 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.75

2.7

2.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

53.8

52.8

54.8

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.7

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

66.1

64.1

68.1

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.6+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

9

7.8

10.2

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_04

Adjusting point

D

Rack position

12.6+-0.

5

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

84

84

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

550--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

800

Advance angle

deg.

1.5

1

2

Timer adjustment_04

Pump speed

r/min

1200

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

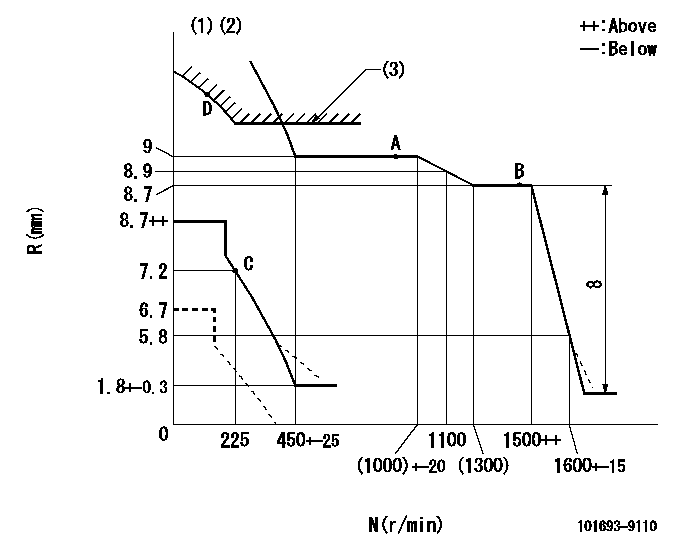

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Damper spring setting: DL

(2)Set the load lever's stop position so that R = aa (N = 0).

(3)Excess fuel setting for starting: SXL

----------

DL=5.8-0.2mm aa=6.7mm SXL=10.9+0.2mm

----------

----------

DL=5.8-0.2mm aa=6.7mm SXL=10.9+0.2mm

----------

0000000901

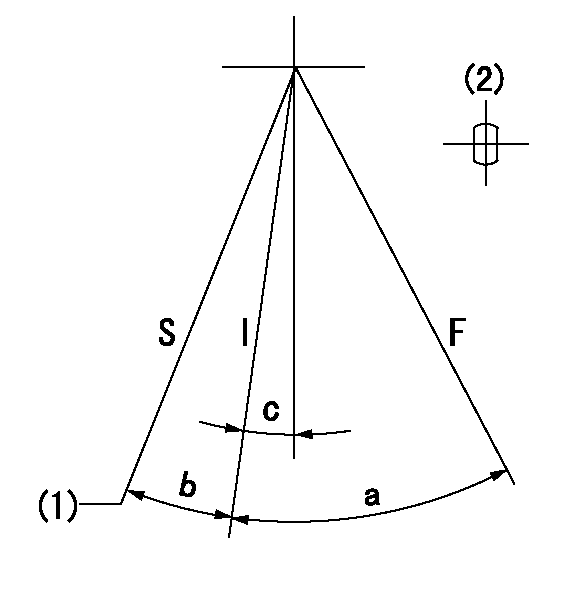

F:Full load

I:Idle

S:Stop

(1)Rack position aa (pump speed bb r/min )

(2)Lever shaft standard

----------

aa=6.7mm bb=0r/min

----------

a=27deg+-3deg b=(14deg)+-3deg c=9.5deg+-5deg

----------

aa=6.7mm bb=0r/min

----------

a=27deg+-3deg b=(14deg)+-3deg c=9.5deg+-5deg

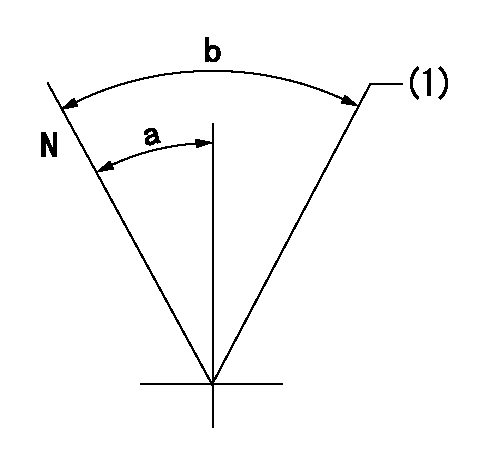

Stop lever angle

N:Pump normal

(1)Rack position = aa

----------

aa=7.2-0.2mm

----------

a=24deg+-5deg b=(48deg)+-5deg

----------

aa=7.2-0.2mm

----------

a=24deg+-5deg b=(48deg)+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Start By:a. remove fuel injection linesb. remove rack actuator package 1. Remove the plug, and move the rack until tool (A) can be installed to hold the rack in the center position. The rack must be in the center position to remove the fuel injection pumps.

To prevent possible personal injury carefully follow the steps below.

2. Put tooling (B), except for the 8S4613 Wrench, in position on the fuel pump housing as shown. Lower the handle to center the adjusting screw with the fuel line seat. With the handle down in the locked position, the adjusting screw must just be in contact with fuel line seat (1). If force is needed to lower the handle or there is a gap, remove the tooling, and make an adjustment to the screw.3. Loosen bushing (2) 1/4 of a turn.4. Put tooling (B) in position on the pump housing with the handle down in the locked position as shown.5. Remove bushing (2) from the pump housing.6. Carefully and slowly lift the handle to release the spring force. Remove the tooling. 7. Install tool (C) on fuel pump (4) as shown.8. Remove seal (3) and fuel pump (4) from the fuel pump housing. 9. Remove spacers (5) from the pump housing. There must be a pump installed on either side of the pump to be removed to install tooling (B). If there is no pump, take a pump already removed, and remove the spring so there will be no spring force, and install it in the pump housing. See Install Fuel Pump. Spacers (5) are the same thickness for each fuel injection pump so they can be mixed. The fuel injection pump plungers and barrels are sets and cannot be mixed.Install Fuel Injection Pumps

1. Install spacers (5) in the fuel pump housing.2. Move the rack until tool (A) can be installed to hold the rack in the center position. The rack must be in the center position to install the fuel injection pumps.3. Install a fuel pump without its spring so that tool (B) can be installed. See Step 5 for correct fuel pump installation. 4. Install tool (C) on the bonnet of the fuel pump as shown.5. Install the fuel pump in the pump housing with the saw cut (slot) (9) in the gear in alignment with small pin (6) in the lifter assembly and groove (8) in the barrel in alignment with large pin (7) in the pump housing. 6. Install the seal and bushing (2) on the fuel pump.7. Put tooling (B) in position on the fuel pump housing as shown.8. Lower the handle slowly and carefully. If the fuel pump is not installed correctly, the handle will not go all the way down. Do not try to use force on it. Remove And Install the tooling and the fuel pump again.9. Make sure the seal is in the correct position, and start to tighten bushing (2). Remove the tooling, and tighten the bushing to a torque of 215

To prevent possible personal injury carefully follow the steps below.

2. Put tooling (B), except for the 8S4613 Wrench, in position on the fuel pump housing as shown. Lower the handle to center the adjusting screw with the fuel line seat. With the handle down in the locked position, the adjusting screw must just be in contact with fuel line seat (1). If force is needed to lower the handle or there is a gap, remove the tooling, and make an adjustment to the screw.3. Loosen bushing (2) 1/4 of a turn.4. Put tooling (B) in position on the pump housing with the handle down in the locked position as shown.5. Remove bushing (2) from the pump housing.6. Carefully and slowly lift the handle to release the spring force. Remove the tooling. 7. Install tool (C) on fuel pump (4) as shown.8. Remove seal (3) and fuel pump (4) from the fuel pump housing. 9. Remove spacers (5) from the pump housing. There must be a pump installed on either side of the pump to be removed to install tooling (B). If there is no pump, take a pump already removed, and remove the spring so there will be no spring force, and install it in the pump housing. See Install Fuel Pump. Spacers (5) are the same thickness for each fuel injection pump so they can be mixed. The fuel injection pump plungers and barrels are sets and cannot be mixed.Install Fuel Injection Pumps

1. Install spacers (5) in the fuel pump housing.2. Move the rack until tool (A) can be installed to hold the rack in the center position. The rack must be in the center position to install the fuel injection pumps.3. Install a fuel pump without its spring so that tool (B) can be installed. See Step 5 for correct fuel pump installation. 4. Install tool (C) on the bonnet of the fuel pump as shown.5. Install the fuel pump in the pump housing with the saw cut (slot) (9) in the gear in alignment with small pin (6) in the lifter assembly and groove (8) in the barrel in alignment with large pin (7) in the pump housing. 6. Install the seal and bushing (2) on the fuel pump.7. Put tooling (B) in position on the fuel pump housing as shown.8. Lower the handle slowly and carefully. If the fuel pump is not installed correctly, the handle will not go all the way down. Do not try to use force on it. Remove And Install the tooling and the fuel pump again.9. Make sure the seal is in the correct position, and start to tighten bushing (2). Remove the tooling, and tighten the bushing to a torque of 215

Have questions with 101693-9110?

Group cross 101693-9110 ZEXEL

Nissan-Diesel

Nissan-Diesel

101693-9110

1670095074

INJECTION-PUMP ASSEMBLY

ND6

ND6