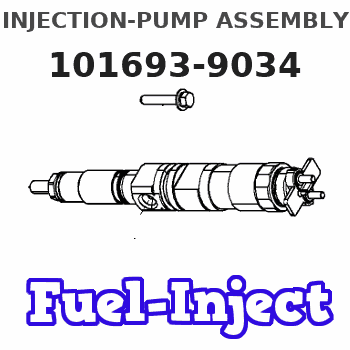

Information injection-pump assembly

ZEXEL

101693-9034

1016939034

NISSAN-DIESEL

16713Z5803

16713z5803

Rating:

Service parts 101693-9034 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-Z5569

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

Zexel num

Bosch num

Firm num

Name

101693-9034

16713Z5803 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FE6B * K

FE6B * K

Information:

Introduction

This document provides information about fuel degradation, which can cause a flow restriction of fuel through the fuel system and premature plugging of the filters. These guidelines should be used to guide service personnel in the use of fuels within diesel engines and covers recognized tests in identifying degredated fuels and best practices in storing fuels.This document can be used as a guide, but it does not provide all the information on all practices and procedures for degraded fuels. This document does not provide all the information for best practices for storing and handling fuels. Refer to Caterpillar Commercial Diesel Engine Fluids Recommendations, SEBU6251 for more information.The Thermal Stability and Oxidation Stability of Fuel

Diesel fuels can deteriorate rapidly for a variety of reasons. When the fuel is stressed and stored for long intervals, degradation and oxidation can occur. Degradation and oxidation are complex chemical changes. These changes lead to deposits or sediment from certain hydrocarbons and traces of naturally occurring nitrogen and sulfur containing compounds in the fuel. Fuel composition and environmental factors influences the process.Diesel fuel is being used as a coolant for high pressure fuel injection systems with high temperature fuel wetted walls. This can stress the fuel in the fuel system. The thermal stress and an increase in recirculation fuel temperature is often responsible for fuel degradation and the formation of gums, resins and sediment, which can cause fuel flow restriction through fuel filters and fuel injection systems.Certain products are often left with the fuel in the fuel system for long periods. This exposes the fuel to oxygen. Complex reactions between the oxygen and the fuel components can generate fuel particulates. The particulates in the fuel system can turn into the sludge that is found in fuel tanks, fuel lines and the fuel filters. This will deteriorate the performance of the fuel system. Degradation also leads to a plugged fuel filter, a restriction to the fuel line and deposit formation in the fuel injection nozzle.Biodiesel and blends of biodiesel have poor thermal stability and oxidation stability compared to petroleum distillate diesel fuels. The use of these biodiesels and blends of biodiesel can accelerate the problems that are addressed in this Special Instruction. Using biodiesel blends above the maximum level approved for the engine is not recommended.Thermal and oxidative degradation of diesel fuel can result in a darkening of fuel color. Fuel color is not necessarily an indication of excessive degradation that will lead to the problems outlined in thisSpecial Instruction, but can be an indicator or degradation If concerns arise about the stability of darkened fuel, the thermal oxidation and oxidative stability tests should be run to confirm actual degradation.Thermal Oxidation Stability

Caterpillar recommends the use of the Accelerated Fuel Oil Stability Test (ASTM D6468). This is a test method that determines the instability of a fuel subjected to a thermal degradation process. This test exposes the fuel to actual operating conditions when the fuel cools the injectors during the engine operation.The test is performed by

This document provides information about fuel degradation, which can cause a flow restriction of fuel through the fuel system and premature plugging of the filters. These guidelines should be used to guide service personnel in the use of fuels within diesel engines and covers recognized tests in identifying degredated fuels and best practices in storing fuels.This document can be used as a guide, but it does not provide all the information on all practices and procedures for degraded fuels. This document does not provide all the information for best practices for storing and handling fuels. Refer to Caterpillar Commercial Diesel Engine Fluids Recommendations, SEBU6251 for more information.The Thermal Stability and Oxidation Stability of Fuel

Diesel fuels can deteriorate rapidly for a variety of reasons. When the fuel is stressed and stored for long intervals, degradation and oxidation can occur. Degradation and oxidation are complex chemical changes. These changes lead to deposits or sediment from certain hydrocarbons and traces of naturally occurring nitrogen and sulfur containing compounds in the fuel. Fuel composition and environmental factors influences the process.Diesel fuel is being used as a coolant for high pressure fuel injection systems with high temperature fuel wetted walls. This can stress the fuel in the fuel system. The thermal stress and an increase in recirculation fuel temperature is often responsible for fuel degradation and the formation of gums, resins and sediment, which can cause fuel flow restriction through fuel filters and fuel injection systems.Certain products are often left with the fuel in the fuel system for long periods. This exposes the fuel to oxygen. Complex reactions between the oxygen and the fuel components can generate fuel particulates. The particulates in the fuel system can turn into the sludge that is found in fuel tanks, fuel lines and the fuel filters. This will deteriorate the performance of the fuel system. Degradation also leads to a plugged fuel filter, a restriction to the fuel line and deposit formation in the fuel injection nozzle.Biodiesel and blends of biodiesel have poor thermal stability and oxidation stability compared to petroleum distillate diesel fuels. The use of these biodiesels and blends of biodiesel can accelerate the problems that are addressed in this Special Instruction. Using biodiesel blends above the maximum level approved for the engine is not recommended.Thermal and oxidative degradation of diesel fuel can result in a darkening of fuel color. Fuel color is not necessarily an indication of excessive degradation that will lead to the problems outlined in thisSpecial Instruction, but can be an indicator or degradation If concerns arise about the stability of darkened fuel, the thermal oxidation and oxidative stability tests should be run to confirm actual degradation.Thermal Oxidation Stability

Caterpillar recommends the use of the Accelerated Fuel Oil Stability Test (ASTM D6468). This is a test method that determines the instability of a fuel subjected to a thermal degradation process. This test exposes the fuel to actual operating conditions when the fuel cools the injectors during the engine operation.The test is performed by

Have questions with 101693-9034?

Group cross 101693-9034 ZEXEL

Nissan-Diesel

Nissan-Diesel

101693-9034

16713Z5803

INJECTION-PUMP ASSEMBLY

FE6B

FE6B