Information injection-pump assembly

BOSCH

9 400 616 064

9400616064

ZEXEL

101692-9310

1016929310

NISSAN-DIESEL

16712Z5509

16712z5509

Rating:

Service parts 101692-9310 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-Z5519

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 616 064

9400616064

ZEXEL

101692-9310

1016929310

NISSAN-DIESEL

16712Z5509

16712z5509

Zexel num

Bosch num

Firm num

Name

101692-9310

9 400 616 064

16712Z5509 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FE6T05 K 14BE INJECTION PUMP ASSY PE6A PE

FE6T05 K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

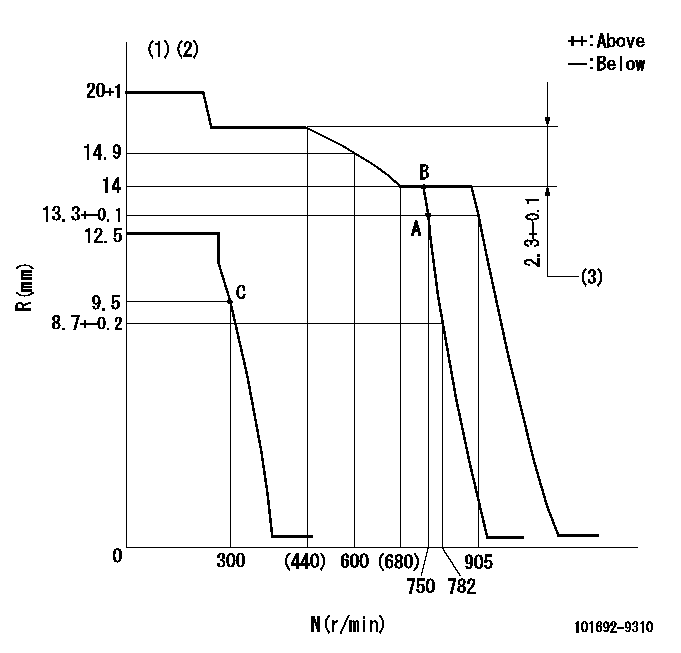

Injection quantity adjustment

Adjusting point

A

Rack position

13.3

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

81.6

79.6

83.6

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

9.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8

6.2

9.8

Max. variation between cylinders

%

0

-12

12

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Rack difference between N = N1 and N = N2

----------

K=15 N1=750r/min N2=390r/min

----------

----------

K=15 N1=750r/min N2=390r/min

----------

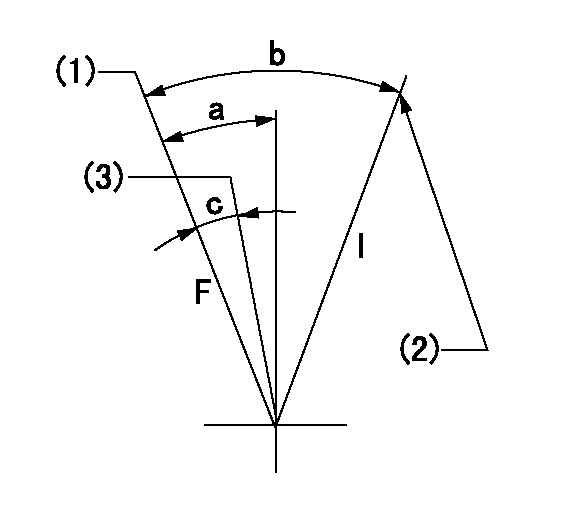

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa. ( At delivery )

(2)Stopper bolt setting

(3)Set the pump speed at bb.

----------

aa=905r/min bb=750r/min

----------

a=11deg+-5deg b=41deg+-5deg c=9deg+-5deg

----------

aa=905r/min bb=750r/min

----------

a=11deg+-5deg b=41deg+-5deg c=9deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

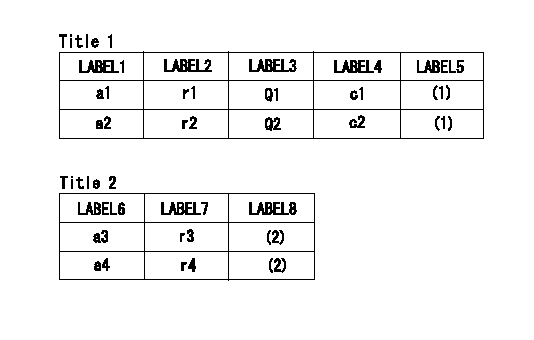

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)-

----------

----------

a1=A a2=C r1=750r/min r2=750r/min Q1=96.5+-2mm3/st Q2=81.6+-2mm3/st c1=+-3% c2=+-3% a3=18 a4=15 r3=950r/min r4=750r/min

----------

----------

a1=A a2=C r1=750r/min r2=750r/min Q1=96.5+-2mm3/st Q2=81.6+-2mm3/st c1=+-3% c2=+-3% a3=18 a4=15 r3=950r/min r4=750r/min

Timing setting

(1)Pump vertical direction

(2)Position of coupling's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Keypad

Keypad (6) is used to control the information that is shown on upper display (4) and lower display (5). The seven keys have two sets of functions, normal functions and service functions. For a description of the service functions of the keys; see the topic Service Mode. The normal functions of the keys are: Left Key- This key only functions when the GSC is in service mode. See the topic Service Mode. Phase Select Key- Selects which phase of the generator output is shown on the GSC. Pressing this key allows the operator to check the voltage, current, and frequency of each phase one at a time. Engine Meter Key- Stops the scrolling of engine conditions on lower display (5) and continuously shows the value for one particular engine condition. The pointer flashes to indicate scrolling is stopped. Pressing the key again, resumes the scrolling of engine conditions. Lamp Test Key- Performs a lamp test on the GSC and the optional alarm module. On the GSC the eight fault indicators are ON continuously, every segment of upper display (4) and lower display (5) are ON. On the optional alarm module all of the indicators are ON and the horn sounds. Alarm Codes Key- If the fault alarm indicator (3) is FLASHING, pressing this key causes the upper display (4) to show the corresponding alarm fault code. Pressing this key again, resumes the showing of generator output information on the upper display (4). If the fault alarm indicator (3) is OFF, this key has no function. For more information on alarm fault codes, see the topic Fault Description. Exit Key- This key only functions when the GSC is in service mode. See the topic Service Mode. Service Mode Key- Pressing this key causes the GSC to enter service mode. See the topic Service Mode.Engine Protection Controls

Engine and generator operating conditions and parameters are monitored and displayed on the Generator Set Control (GSC) Panel. The GSC detects faults that are alarm and shutdown conditions.The engine will continue to run when an alarm condition fault is displayed. The engine will automatically shut down if one of the following faults is detected and displayed.* Low oil pressure,* High coolant temperature,* Engine overspeed,* Low coolant level (if provided),* Engine overcrank.The activation of the Emergency Stop Push Button (ESPB) is also provided on the control panel.Fault Indicators

The eight fault indicators, located on the front of the GSC, are used to show and describe a fault that is present. * The yellow fault alarm indicator flashes when the GSC detects a fault that is an alarm condition. The engine continues to run and start. The fault alarm indicator is accompanied by an alarm fault code that is shown on the upper display when the Alarm Codes Key is pressed. Refer to Service Manual SENR5827 for fault code descriptions. * A red fault shutdown indicator flashes when the GSC detects a fault that is a shutdown condition. The engine is shutdown if it is running

Keypad (6) is used to control the information that is shown on upper display (4) and lower display (5). The seven keys have two sets of functions, normal functions and service functions. For a description of the service functions of the keys; see the topic Service Mode. The normal functions of the keys are: Left Key- This key only functions when the GSC is in service mode. See the topic Service Mode. Phase Select Key- Selects which phase of the generator output is shown on the GSC. Pressing this key allows the operator to check the voltage, current, and frequency of each phase one at a time. Engine Meter Key- Stops the scrolling of engine conditions on lower display (5) and continuously shows the value for one particular engine condition. The pointer flashes to indicate scrolling is stopped. Pressing the key again, resumes the scrolling of engine conditions. Lamp Test Key- Performs a lamp test on the GSC and the optional alarm module. On the GSC the eight fault indicators are ON continuously, every segment of upper display (4) and lower display (5) are ON. On the optional alarm module all of the indicators are ON and the horn sounds. Alarm Codes Key- If the fault alarm indicator (3) is FLASHING, pressing this key causes the upper display (4) to show the corresponding alarm fault code. Pressing this key again, resumes the showing of generator output information on the upper display (4). If the fault alarm indicator (3) is OFF, this key has no function. For more information on alarm fault codes, see the topic Fault Description. Exit Key- This key only functions when the GSC is in service mode. See the topic Service Mode. Service Mode Key- Pressing this key causes the GSC to enter service mode. See the topic Service Mode.Engine Protection Controls

Engine and generator operating conditions and parameters are monitored and displayed on the Generator Set Control (GSC) Panel. The GSC detects faults that are alarm and shutdown conditions.The engine will continue to run when an alarm condition fault is displayed. The engine will automatically shut down if one of the following faults is detected and displayed.* Low oil pressure,* High coolant temperature,* Engine overspeed,* Low coolant level (if provided),* Engine overcrank.The activation of the Emergency Stop Push Button (ESPB) is also provided on the control panel.Fault Indicators

The eight fault indicators, located on the front of the GSC, are used to show and describe a fault that is present. * The yellow fault alarm indicator flashes when the GSC detects a fault that is an alarm condition. The engine continues to run and start. The fault alarm indicator is accompanied by an alarm fault code that is shown on the upper display when the Alarm Codes Key is pressed. Refer to Service Manual SENR5827 for fault code descriptions. * A red fault shutdown indicator flashes when the GSC detects a fault that is a shutdown condition. The engine is shutdown if it is running

Have questions with 101692-9310?

Group cross 101692-9310 ZEXEL

Nissan-Diesel

101692-9310

9 400 616 064

16712Z5509

INJECTION-PUMP ASSEMBLY

FE6T05

FE6T05