Information injection-pump assembly

ZEXEL

101692-3710

1016923710

KOMATSU

6207711190

6207711190

Rating:

Cross reference number

ZEXEL

101692-3710

1016923710

KOMATSU

6207711190

6207711190

Zexel num

Bosch num

Firm num

Name

101692-3710

6207711190 KOMATSU

INJECTION-PUMP ASSEMBLY

S6D95L * K

S6D95L * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

52.8

51.8

53.8

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

9.3+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

12.5

11.5

13.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

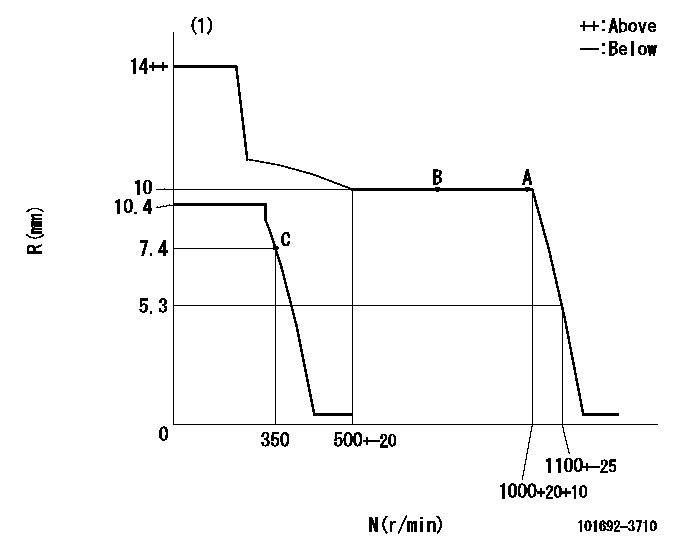

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

----------

K=8

----------

----------

K=8

----------

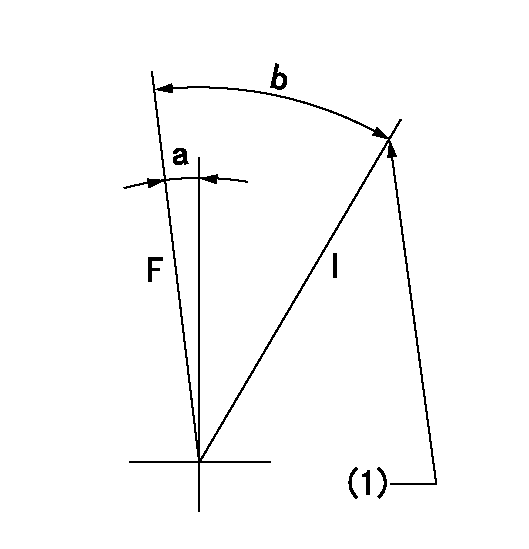

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=3deg+-5deg b=27deg+-5deg

----------

----------

a=3deg+-5deg b=27deg+-5deg

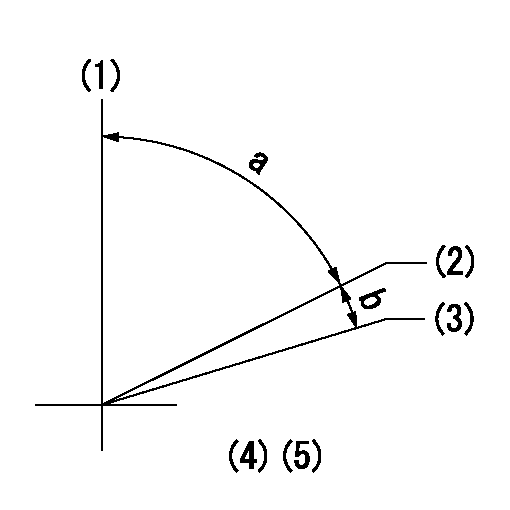

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of key groove at No 1 cylinder's beginning of injection

(3)Stamp aligning marks on the pump housing flange.

(4)-

(5)-

----------

----------

a=59deg36min+-3deg b=0deg24min+-30min

----------

----------

a=59deg36min+-3deg b=0deg24min+-30min

Information:

Alternator and Fan Drive Belts

Inspect/Adjust/Replace

Your engine will be equipped with a water pump belt and a pair of belts for the fan drive and alternator. Inspect the condition and adjustment of alternator and fan drive belts. Inspect all drive belts and replace if they show any signs of wear.Check and adjust the belt tension to minimize belt slippage. If belts are too loose, they vibrate enough to cause unnecessary wear on the belts and pulleys. If belts are too tight, unnecessary stresses are placed upon the pulley bearings and belts which might shorten the life of both.To Adjust Drive Belt

The alternator is used for tension adjustment. Correctly adjusted belts will deflect approximately 9 to 15 mm (3/8 to 5/8 inch). If new belt(s) are installed, check belt adjustment again after 30 minutes of operation.To adjust the belt tension, loosen the alternator bolts and slide the alternator in the desired direction to increase or decrease the belt tension. 1. To adjust the alternator drive belt, loosen mounting bolt (1) and the adjusting bracket bolt (2).2. Move the alternator in or out as required to obtain the correct adjustment. Tighten the bolts (1) and (2). Do not overtighten.3. If new belts are installed, check belt adjustment again after 30 minutes of engine operation.To Adjust Water Pump Belt

1. To adjust the water pump drive belt, loosen mounting bolt and bracket bolt.2. Move water pump idler pulley in or out as required to obtain the correct adjustment.3. To make the correct adjustment, use the square hole in the mounting bracket or bolt to apply tension.4. Tighten bolts. Do not overtighten. The water pump belt is not used to drive any other accessories. Excessive tightening can damage the water pump bearings or shaft.5. If a new belt is installed, check the belt adjustment again after 30 minutes of engine operation at rated speed.Fan Drive Bearing

Lubricate

Lubricate one fitting with Caterpillar 2S3230 SPG grease. Refer to the Lubrication Specifications section in this Manual for the proper lubricating grease to be used.Inspect the fan drive pulley assembly. It should be difficult to detect movement of the shaft in the bearing. If the shaft is loose in the bearings, an inspection of the internal components should be made.The bearing end play should be 0.03 to 0.23 mm (.001 to .009 inch). The radial play should be no greater than 0.13 mm (.005 inch). Fan Clutch-For emergency operation or electrical override, use one M6 x 1 cap screw inserted in fan spider clearance holes to allow continuous operation of fan. Have fan clutch repaired at next stop.

Do NOT operate engine with this condition for long periods of time because an engine over cooling problem (low operating temperatures) will cause sludge formation and excessive carbon build-up on critical engine components.

If the assembly should require disassembly, refer to the Service Manual for the procedure.Battery

Check the following at least every 6 months, and more often if conditions require.Tighten Terminals

* Clean the top of the batteries with a clean cloth. Loosen and

Inspect/Adjust/Replace

Your engine will be equipped with a water pump belt and a pair of belts for the fan drive and alternator. Inspect the condition and adjustment of alternator and fan drive belts. Inspect all drive belts and replace if they show any signs of wear.Check and adjust the belt tension to minimize belt slippage. If belts are too loose, they vibrate enough to cause unnecessary wear on the belts and pulleys. If belts are too tight, unnecessary stresses are placed upon the pulley bearings and belts which might shorten the life of both.To Adjust Drive Belt

The alternator is used for tension adjustment. Correctly adjusted belts will deflect approximately 9 to 15 mm (3/8 to 5/8 inch). If new belt(s) are installed, check belt adjustment again after 30 minutes of operation.To adjust the belt tension, loosen the alternator bolts and slide the alternator in the desired direction to increase or decrease the belt tension. 1. To adjust the alternator drive belt, loosen mounting bolt (1) and the adjusting bracket bolt (2).2. Move the alternator in or out as required to obtain the correct adjustment. Tighten the bolts (1) and (2). Do not overtighten.3. If new belts are installed, check belt adjustment again after 30 minutes of engine operation.To Adjust Water Pump Belt

1. To adjust the water pump drive belt, loosen mounting bolt and bracket bolt.2. Move water pump idler pulley in or out as required to obtain the correct adjustment.3. To make the correct adjustment, use the square hole in the mounting bracket or bolt to apply tension.4. Tighten bolts. Do not overtighten. The water pump belt is not used to drive any other accessories. Excessive tightening can damage the water pump bearings or shaft.5. If a new belt is installed, check the belt adjustment again after 30 minutes of engine operation at rated speed.Fan Drive Bearing

Lubricate

Lubricate one fitting with Caterpillar 2S3230 SPG grease. Refer to the Lubrication Specifications section in this Manual for the proper lubricating grease to be used.Inspect the fan drive pulley assembly. It should be difficult to detect movement of the shaft in the bearing. If the shaft is loose in the bearings, an inspection of the internal components should be made.The bearing end play should be 0.03 to 0.23 mm (.001 to .009 inch). The radial play should be no greater than 0.13 mm (.005 inch). Fan Clutch-For emergency operation or electrical override, use one M6 x 1 cap screw inserted in fan spider clearance holes to allow continuous operation of fan. Have fan clutch repaired at next stop.

Do NOT operate engine with this condition for long periods of time because an engine over cooling problem (low operating temperatures) will cause sludge formation and excessive carbon build-up on critical engine components.

If the assembly should require disassembly, refer to the Service Manual for the procedure.Battery

Check the following at least every 6 months, and more often if conditions require.Tighten Terminals

* Clean the top of the batteries with a clean cloth. Loosen and

Have questions with 101692-3710?

Group cross 101692-3710 ZEXEL

Komatsu

101692-3710

6207711190

INJECTION-PUMP ASSEMBLY

S6D95L

S6D95L