Information injection-pump assembly

ZEXEL

101692-3610

1016923610

Rating:

Cross reference number

ZEXEL

101692-3610

1016923610

Zexel num

Bosch num

Firm num

Name

101692-3610

KOMATSU

INJECTION-PUMP ASSEMBLY

6D95L *

6D95L *

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

31.7

30.7

32.7

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

10.5+-0.

5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

10.5

9.5

11.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

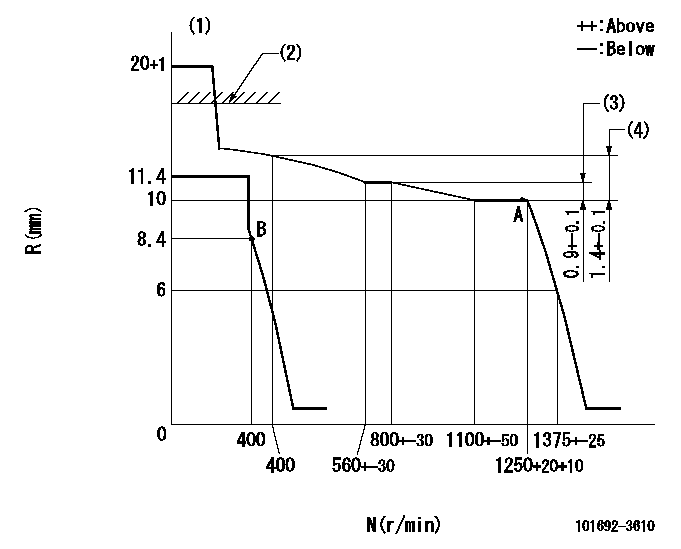

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK CAP: R1

(3)Rack difference between N = N1 and N = N2

(4)Rack difference between N = N3 and N = N4

----------

K=19 R1=(17.5)mm N1=1250r/min N2=750r/min N3=1250r/min N4=400r/min

----------

----------

K=19 R1=(17.5)mm N1=1250r/min N2=750r/min N3=1250r/min N4=400r/min

----------

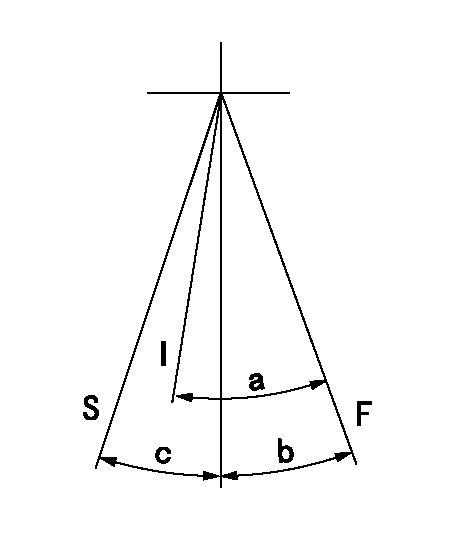

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=27deg+-5deg b=26deg+-5deg c=32deg+-3deg

----------

----------

a=27deg+-5deg b=26deg+-5deg c=32deg+-3deg

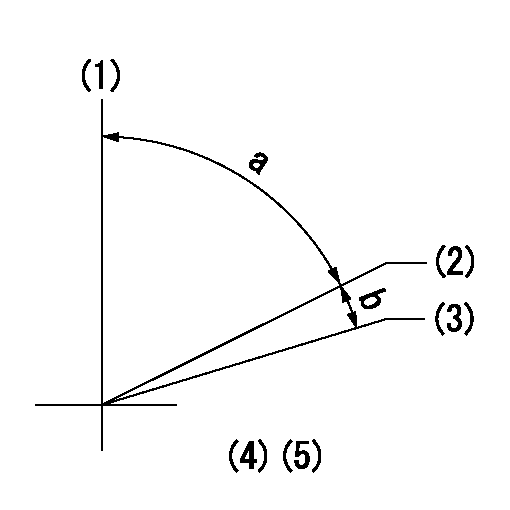

Timing setting

(1)Pump vertical direction

(2)Position of key groove at No 1 cylinder's beginning of injection

(3)Stamp aligning marks on the pump housing flange.

(4)-

(5)-

----------

----------

a=59deg36min+-3deg b=0deg24min+-30min

----------

----------

a=59deg36min+-3deg b=0deg24min+-30min

Information:

Engine Lifting

When it is necessary to remove a component on an angle, remember that the capacity of an eyebolt is less as the angle between the supporting members and the object becomes less than 90 °. Eyebolts and brackets should never be bent and should only be loaded in tension.

Use a hoist to remove heavy components. Lift the engine by using an adjustable lifting beam. All supporting members (chains and cables) should be parallel to each other, and as near perpendicular as possible to the top of the object being lifted. Some removals require the use of lifting fixtures to obtain proper balance and to provide safe handling.To remove the engine, use the two lifting eyes on the engine. Lifting eyes are designed for the arrangement as sold. Alterations to lifting eyes and/or arrangement weight make the lifting devices inadequate and deficient. If you make alterations, you are responsible for providing adequate lifting devices.Engine Storage

If an engine remains out of service and its use is not immediately planned, special precautions should be taken. If the engine will not be or has not been started for several weeks, the lubricating oil will drain from the cylinder walls and piston rings. Rust can form on the cylinder liner surface, which will increase engine wear and may result in shorter engine life.If freezing temperatures are expected, check the cooling system for adequate protection against freezing. A 50/50 solution of Caterpillar (permanent-type) Antifreeze and approved water will give protection to -37°C (-34°F).If it will be impossible to start and exercise the engine periodically, consult Caterpillar for instructions to prepare your engine for longer storage periods.

When it is necessary to remove a component on an angle, remember that the capacity of an eyebolt is less as the angle between the supporting members and the object becomes less than 90 °. Eyebolts and brackets should never be bent and should only be loaded in tension.

Use a hoist to remove heavy components. Lift the engine by using an adjustable lifting beam. All supporting members (chains and cables) should be parallel to each other, and as near perpendicular as possible to the top of the object being lifted. Some removals require the use of lifting fixtures to obtain proper balance and to provide safe handling.To remove the engine, use the two lifting eyes on the engine. Lifting eyes are designed for the arrangement as sold. Alterations to lifting eyes and/or arrangement weight make the lifting devices inadequate and deficient. If you make alterations, you are responsible for providing adequate lifting devices.Engine Storage

If an engine remains out of service and its use is not immediately planned, special precautions should be taken. If the engine will not be or has not been started for several weeks, the lubricating oil will drain from the cylinder walls and piston rings. Rust can form on the cylinder liner surface, which will increase engine wear and may result in shorter engine life.If freezing temperatures are expected, check the cooling system for adequate protection against freezing. A 50/50 solution of Caterpillar (permanent-type) Antifreeze and approved water will give protection to -37°C (-34°F).If it will be impossible to start and exercise the engine periodically, consult Caterpillar for instructions to prepare your engine for longer storage periods.

Have questions with 101692-3610?

Group cross 101692-3610 ZEXEL

Komatsu

101692-3610

INJECTION-PUMP ASSEMBLY

6D95L

6D95L