Information injection-pump assembly

ZEXEL

101692-3370

1016923370

Rating:

Cross reference number

ZEXEL

101692-3370

1016923370

Zexel num

Bosch num

Firm num

Name

101692-3370

KOMATSU

INJECTION-PUMP ASSEMBLY

S6D95L *

S6D95L *

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.6

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

54.8

53.8

55.8

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

10.5+-0.

5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

12.5

11.5

13.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

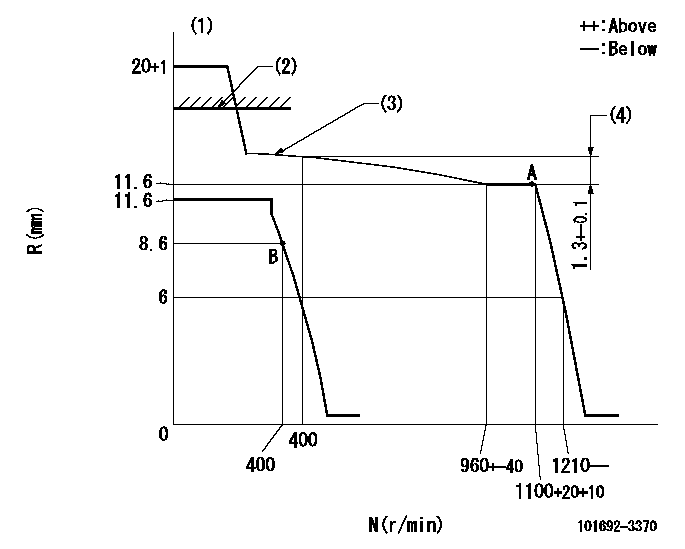

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK CAP: R1

(3)The torque control spring must does not have a set force.

(4)Rack difference between N = N1 and N = N2

----------

K=11 R1=(17.5)mm N1=1100r/min N2=400r/min

----------

----------

K=11 R1=(17.5)mm N1=1100r/min N2=400r/min

----------

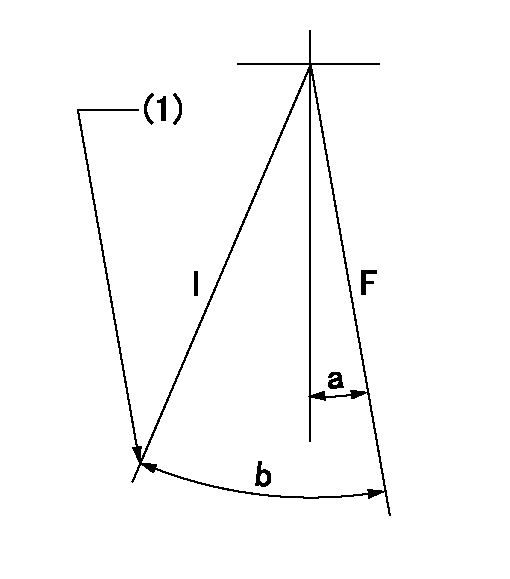

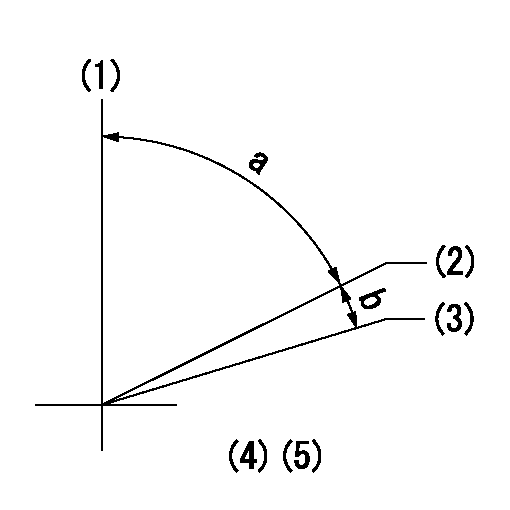

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=13deg+-5deg b=40deg+-5deg

----------

----------

a=13deg+-5deg b=40deg+-5deg

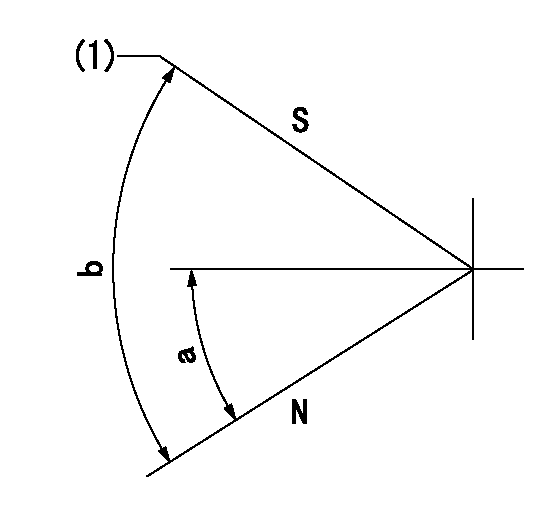

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At shipping

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of key groove at No 1 cylinder's beginning of injection

(3)Stamp aligning marks on the pump housing flange.

(4)-

(5)-

----------

----------

a=59deg36min+-3deg b=0deg24min+-30min

----------

----------

a=59deg36min+-3deg b=0deg24min+-30min

Information:

Caterpillar Reference Material

Oil

SEBD0640 Oil and Your EngineSEBU6310 EMA Engine Oil Data BookPEDP7105 Scheduled Oil SamplingPEDP7122 Question & Answer BookletPEHP0002 Cat Molybdenum Grease (MPGM)PEHP0003 Cat Lithium Grease (MPGL)PEHP0017 Cat Special Purpose Grease (SPG)PEHP1020 Cat Diesel Engine Oil (CF-4) Data Sheet (North America)PEHP1026 Cat Diesel Engine Oil (CF-4) Data Sheet (International)PEHP6001 How to Take a Good Oil SamplePEWP9733 Cat Fluids SelectorFuel

SEBD0717 Diesel Fuels and Your EngineSEHS7067 Fuels for Caterpillar Diesel EnginesLEKQ3363 Caterpillar Engine Data Sheet 60.1 (Fuels Recommended For Use In Caterpillar Truck Engines)Coolant

SEBD0518 Know Your Cooling SystemSEBD0970 Coolant and Your EngineService Manuals

SEBR0514 Low Emission SystemSEBR0560 3406C (Mechanical) Service Manual (3ZJ16182 and Up, 5KJ07800 and Up)SENR5505 3406C (Electronic) Service Manual (4CK00846 and Up)Special Instructions

The following Special Instructions pertain to the operation, maintenance, diagnostic tooling and programming of the PEEC system. Some of these publications will be included in the tool kits, the others will be available thru your Caterpillar dealer.SEHS7808 Using the 6V3060 Low Emission System TesterSEHS8622 Using the FT1984 Air-To-Air Aftercooler Leak Test GroupSEHS8627 and SEHS9083 Using the 1U5540 Tool GroupSEHS8741 Using the 8C5919 Service Program ModuleSEHS8742 Using the 8T8697 Electronic Control Analyzer Programmer (ECAP)SEHS8743 Using the 8C4629 Digital Diagnostic Tool (DDT) with Programmable Electronic Engine Control ModuleSEHS8746 Using the 1U5540 Tool GroupSEHS8807 Programmable Electronic Engine Control Screen Map(s)SEHS9031 Storage Procedure for Caterpillar ProductsSEHS9349 Using the 8C5919 Service Program ModuleMiscellaneous

LEBT8121 Truck Engine Application and Installation Guide (4-88)LEDT4211 PAR DirectoryLEDT5092 Driving Techniques For Maximum Fuel EconomyLEGT5087 Truck Engine Application and Installation GuideLEHQ6101 General Instructions and Application GuideLEKT8467 Specing for Peak PerformanceLEXT7056 Performance Analysis Report (PAR) Testing for 3406 Electronic Truck EnginesPEDP0026 Power Analysis ReportSEBD0794 3400 Engine-Major Component Performance GuideSEBF8029 Index to Guidelines for Reusable Parts and Salvage OperationsSEBF8062 Guideline for Reusable Parts (Cleaning and Inspection of Air Filters)SELF5052 Emission Related Components WarrantyAdditional Reference Material

ASTM D217-68 - Worked PenetrationASTM D2896 - TBN MeasurementsASTM D2982BASTM D3828AASTM D445ASTM D893ASTM 4985-89 - GM-6038M SpecificationASTM Specs can normally be obtained from your local technological society, library or college.SAE J313 - Diesel FuelsSAE J754 - NomenclatureSAE J183 - ClassificationSAE Specs can be found in your SAE handbook or can be obtained from your local library, college or technological society.* SAE handbooks can be obtained directly from:SAE International

400 Commonwealth Drive

Warrendale, PA USA 15096-0001

All of the above publications are available through your Caterpillar dealer.Customer Specified Reference Numbers

Below is space for information on the programmed specifications to be filled in by the owner. ENGINE: 3406 Electronic* VEHICLE IDENTIFICATION NO. (VIN)____________________* RATING SELECTION NUMBER____________________* CUSTOMER PASSWORDS: Password No. 1 ____________________Password No. 2 ____________________* VEHICLE SPEED PARAMETERS: Vehicle Speed Calibration____________________ppmTachometer Calibration____________________pprVehicle Speed Limit (VSL)____________________mph (km/h)5 mph Vehicle Speed Droop ____________________Engine RPM @ VSL____________________rpm* CRUISE CONTROL (CC) PARAMETERS: Low Cruise Control Speed Set Limit (LCC)____________________mph (km/h)High Cruise Control Speed Set Limit (HCC)____________________mph (km/h)Engine Retarder Mode ____________________Cruise Switch Configuration ____________________* PTO GOVERNOR PARAMETERS: PTO Mode Speed Limit____________________mph (km/h)PTO Mode Engine Speed (rpm) Limit____________________rpmPTO Engine Speed Ramp Rate____________________rpm/sec.* PROGRESSIVE SHIFTING PARAMETERS: Low Gears #1 (LoGr#1) Engine RPM Limit____________________rpmLow Gears #1 (LoGr#1)

Oil

SEBD0640 Oil and Your EngineSEBU6310 EMA Engine Oil Data BookPEDP7105 Scheduled Oil SamplingPEDP7122 Question & Answer BookletPEHP0002 Cat Molybdenum Grease (MPGM)PEHP0003 Cat Lithium Grease (MPGL)PEHP0017 Cat Special Purpose Grease (SPG)PEHP1020 Cat Diesel Engine Oil (CF-4) Data Sheet (North America)PEHP1026 Cat Diesel Engine Oil (CF-4) Data Sheet (International)PEHP6001 How to Take a Good Oil SamplePEWP9733 Cat Fluids SelectorFuel

SEBD0717 Diesel Fuels and Your EngineSEHS7067 Fuels for Caterpillar Diesel EnginesLEKQ3363 Caterpillar Engine Data Sheet 60.1 (Fuels Recommended For Use In Caterpillar Truck Engines)Coolant

SEBD0518 Know Your Cooling SystemSEBD0970 Coolant and Your EngineService Manuals

SEBR0514 Low Emission SystemSEBR0560 3406C (Mechanical) Service Manual (3ZJ16182 and Up, 5KJ07800 and Up)SENR5505 3406C (Electronic) Service Manual (4CK00846 and Up)Special Instructions

The following Special Instructions pertain to the operation, maintenance, diagnostic tooling and programming of the PEEC system. Some of these publications will be included in the tool kits, the others will be available thru your Caterpillar dealer.SEHS7808 Using the 6V3060 Low Emission System TesterSEHS8622 Using the FT1984 Air-To-Air Aftercooler Leak Test GroupSEHS8627 and SEHS9083 Using the 1U5540 Tool GroupSEHS8741 Using the 8C5919 Service Program ModuleSEHS8742 Using the 8T8697 Electronic Control Analyzer Programmer (ECAP)SEHS8743 Using the 8C4629 Digital Diagnostic Tool (DDT) with Programmable Electronic Engine Control ModuleSEHS8746 Using the 1U5540 Tool GroupSEHS8807 Programmable Electronic Engine Control Screen Map(s)SEHS9031 Storage Procedure for Caterpillar ProductsSEHS9349 Using the 8C5919 Service Program ModuleMiscellaneous

LEBT8121 Truck Engine Application and Installation Guide (4-88)LEDT4211 PAR DirectoryLEDT5092 Driving Techniques For Maximum Fuel EconomyLEGT5087 Truck Engine Application and Installation GuideLEHQ6101 General Instructions and Application GuideLEKT8467 Specing for Peak PerformanceLEXT7056 Performance Analysis Report (PAR) Testing for 3406 Electronic Truck EnginesPEDP0026 Power Analysis ReportSEBD0794 3400 Engine-Major Component Performance GuideSEBF8029 Index to Guidelines for Reusable Parts and Salvage OperationsSEBF8062 Guideline for Reusable Parts (Cleaning and Inspection of Air Filters)SELF5052 Emission Related Components WarrantyAdditional Reference Material

ASTM D217-68 - Worked PenetrationASTM D2896 - TBN MeasurementsASTM D2982BASTM D3828AASTM D445ASTM D893ASTM 4985-89 - GM-6038M SpecificationASTM Specs can normally be obtained from your local technological society, library or college.SAE J313 - Diesel FuelsSAE J754 - NomenclatureSAE J183 - ClassificationSAE Specs can be found in your SAE handbook or can be obtained from your local library, college or technological society.* SAE handbooks can be obtained directly from:SAE International

400 Commonwealth Drive

Warrendale, PA USA 15096-0001

All of the above publications are available through your Caterpillar dealer.Customer Specified Reference Numbers

Below is space for information on the programmed specifications to be filled in by the owner. ENGINE: 3406 Electronic* VEHICLE IDENTIFICATION NO. (VIN)____________________* RATING SELECTION NUMBER____________________* CUSTOMER PASSWORDS: Password No. 1 ____________________Password No. 2 ____________________* VEHICLE SPEED PARAMETERS: Vehicle Speed Calibration____________________ppmTachometer Calibration____________________pprVehicle Speed Limit (VSL)____________________mph (km/h)5 mph Vehicle Speed Droop ____________________Engine RPM @ VSL____________________rpm* CRUISE CONTROL (CC) PARAMETERS: Low Cruise Control Speed Set Limit (LCC)____________________mph (km/h)High Cruise Control Speed Set Limit (HCC)____________________mph (km/h)Engine Retarder Mode ____________________Cruise Switch Configuration ____________________* PTO GOVERNOR PARAMETERS: PTO Mode Speed Limit____________________mph (km/h)PTO Mode Engine Speed (rpm) Limit____________________rpmPTO Engine Speed Ramp Rate____________________rpm/sec.* PROGRESSIVE SHIFTING PARAMETERS: Low Gears #1 (LoGr#1) Engine RPM Limit____________________rpmLow Gears #1 (LoGr#1)

Have questions with 101692-3370?

Group cross 101692-3370 ZEXEL

Komatsu

Komatsu

101692-3370

INJECTION-PUMP ASSEMBLY

S6D95L

S6D95L