Information injection-pump assembly

ZEXEL

101692-2520

1016922520

HINO

220201220A

220201220a

Rating:

Service parts 101692-2520 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

15.

NOZZLE SET

Cross reference number

ZEXEL

101692-2520

1016922520

HINO

220201220A

220201220a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle

105780-0020

Bosch type code

DN4SD24T

Nozzle holder

105031-2010

Bosch type code

KB56SD273

Opening pressure

MPa

16

Opening pressure

kgf/cm2

120

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.1

2.05

2.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

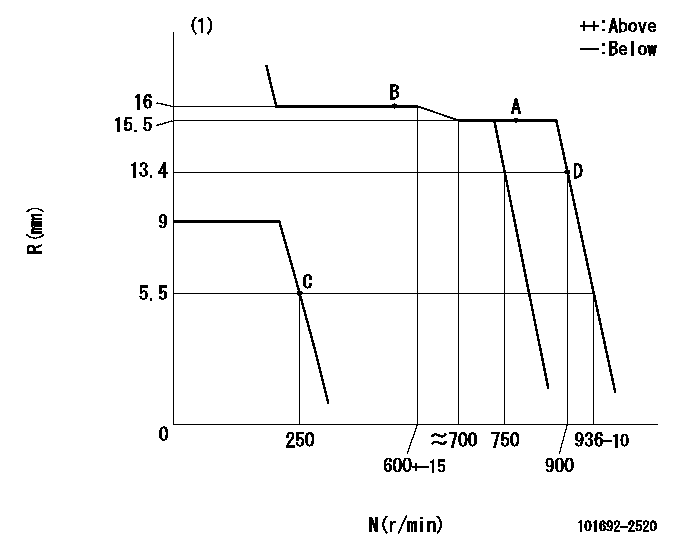

Injection quantity adjustment

Adjusting point

A

Rack position

15.5

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

146

143

149

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

16

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

143

138.5

147.5

Max. variation between cylinders

%

0

-3

3

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

5.5+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

20

17.5

22.5

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

13.4

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

134

128.8

139.2

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

----------

K=10

----------

----------

K=10

----------

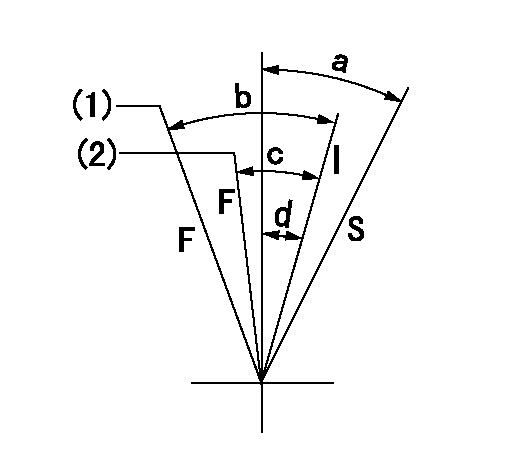

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Set the pump speed at aa

(2)Set the pump speed at bb.

----------

aa=900r/min bb=750r/min

----------

a=32deg+-3deg b=32.5deg+-5deg c=25.5deg+-5deg d=25deg

----------

aa=900r/min bb=750r/min

----------

a=32deg+-3deg b=32.5deg+-5deg c=25.5deg+-5deg d=25deg

Information:

Air-to-air aftercooling systems are simple, reliable and easy to maintain and provide for one or more benefits.* Improved fuel consumption* Lower emissions* Increased powerOperation of ATAAC

Heated compressed air from the engine turbocharger is conveyed to an air-to-air aftercooler that is positioned in front of the engine radiator. The combined effect of the engine fan and ram air moves cooled air through the system to reduce the turbocharged air temperature before it enters the engine intake manifold.Lower intake air temperature allows more air to enter the cylinder, resulting in more complete fuel combustion and reduced exhaust emissions.Air-to-air aftercoolers can achieve charge air temperatures lower than water-to-air systems for additional efficiency.

To maintain an adequate water pump cavitation temperature for efficient water pump performance in an Air-to-Air aftercooled engine, Caterpillar recommends that the coolant mix contain a minimum of 30% Caterpillar Antifreeze, GM-6038M or equivalent. Only use a greater concentration (above 30%) of antifreeze as needed for anticipated outside temperatures.Ethylene glycol raises the boiling point of water.Do not exceed a coolant mixture of 60% ethylene glycol to water since a concentration above 60% ethylene glycol will reduce the engine's freeze protection and increase the possibility of deposit formation in the cooling system.Downtherm 209 Full-Fill coolant cannot be substituted for ethylene glycol, due to its inability to raise the water pump cavitation temperature. Downtherm 209 Full-Fill coolant lowers the boiling point of water.

Air Intake System

Never run the engine without an air cleaner installed or with a damaged air cleaner. Dirt will enter the engine and cause premature wear and damage to engine components.Service the air cleaner at regular intervals as determined by the operating environmental dust conditions. Check the air cleaner service indicator (if equipped) daily.As the air cleaner element becomes plugged, the difference of air pressure between the inlet side (dirty side) and the engine side (clean side) will increase. Service the air cleaners regularly or when the air cleaner service indicator diaphragm enters the red zone or the red piston locks in the visible position.Inspect the air intake hoses, elbows and gaskets for cracks or damage, replace as needed. Check for loose clamps, tighten as needed.Check the precleaner (if equipped) daily for accumulation of dust and debris.The Caterpillar air cleaner element may be cleaned up to six times, but must be replaced annually. The element when cleaned, should be thoroughly checked for rips and tears in the filter material and for gasket damage.Winter Fronts

Caterpillar discourages the use of winter fronts or other air flow restriction devices mounted in front of radiators with air-to-air aftercooled engines. Air flow restriction can cause higher exhaust temperatures, power loss, excessive fan usage, a reduction in fuel economy and possible engine damage.If a winter front must be used, then it should have a permanent circular or diamond-shaped opening directly in line with the fan hub and must have a minimum opening dimension of at least 120 sq. in. (770 sq. cm).A centered opening, versus a side or edge winter front opening is specified to provide

Heated compressed air from the engine turbocharger is conveyed to an air-to-air aftercooler that is positioned in front of the engine radiator. The combined effect of the engine fan and ram air moves cooled air through the system to reduce the turbocharged air temperature before it enters the engine intake manifold.Lower intake air temperature allows more air to enter the cylinder, resulting in more complete fuel combustion and reduced exhaust emissions.Air-to-air aftercoolers can achieve charge air temperatures lower than water-to-air systems for additional efficiency.

To maintain an adequate water pump cavitation temperature for efficient water pump performance in an Air-to-Air aftercooled engine, Caterpillar recommends that the coolant mix contain a minimum of 30% Caterpillar Antifreeze, GM-6038M or equivalent. Only use a greater concentration (above 30%) of antifreeze as needed for anticipated outside temperatures.Ethylene glycol raises the boiling point of water.Do not exceed a coolant mixture of 60% ethylene glycol to water since a concentration above 60% ethylene glycol will reduce the engine's freeze protection and increase the possibility of deposit formation in the cooling system.Downtherm 209 Full-Fill coolant cannot be substituted for ethylene glycol, due to its inability to raise the water pump cavitation temperature. Downtherm 209 Full-Fill coolant lowers the boiling point of water.

Air Intake System

Never run the engine without an air cleaner installed or with a damaged air cleaner. Dirt will enter the engine and cause premature wear and damage to engine components.Service the air cleaner at regular intervals as determined by the operating environmental dust conditions. Check the air cleaner service indicator (if equipped) daily.As the air cleaner element becomes plugged, the difference of air pressure between the inlet side (dirty side) and the engine side (clean side) will increase. Service the air cleaners regularly or when the air cleaner service indicator diaphragm enters the red zone or the red piston locks in the visible position.Inspect the air intake hoses, elbows and gaskets for cracks or damage, replace as needed. Check for loose clamps, tighten as needed.Check the precleaner (if equipped) daily for accumulation of dust and debris.The Caterpillar air cleaner element may be cleaned up to six times, but must be replaced annually. The element when cleaned, should be thoroughly checked for rips and tears in the filter material and for gasket damage.Winter Fronts

Caterpillar discourages the use of winter fronts or other air flow restriction devices mounted in front of radiators with air-to-air aftercooled engines. Air flow restriction can cause higher exhaust temperatures, power loss, excessive fan usage, a reduction in fuel economy and possible engine damage.If a winter front must be used, then it should have a permanent circular or diamond-shaped opening directly in line with the fan hub and must have a minimum opening dimension of at least 120 sq. in. (770 sq. cm).A centered opening, versus a side or edge winter front opening is specified to provide