Information injection-pump assembly

ZEXEL

101691-9880

1016919880

NISSAN-DIESEL

16801Z5501

16801z5501

Rating:

Cross reference number

ZEXEL

101691-9880

1016919880

NISSAN-DIESEL

16801Z5501

16801z5501

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

RED3 control unit part number

407910-2

470

RED3 rack sensor specifications

mm

15

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Rack position

(13)

Vist

V

1.4

1.4

1.4

Pump speed

r/min

550

550

550

Average injection quantity

mm3/st.

84.1

83.1

85.1

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Injection quantity adjustment_02

Rack position

(8.9)

Vist

V

2.2

2.1

2.3

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

8

6.2

9.8

Max. variation between cylinders

%

0

-10

10

Test data Ex:

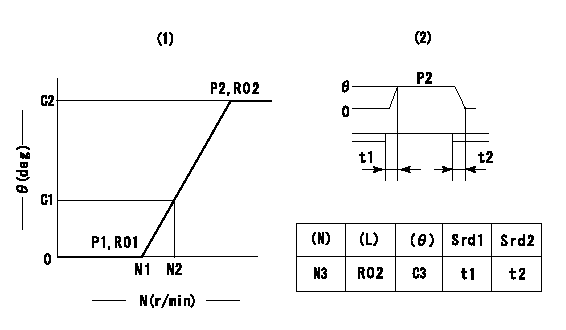

Governor adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1.5+-0.2mm N3=800r/min C3=(4deg) t1=2--sec. t2=2--sec.

----------

N1=1200++r/min N2=1400r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=2.5--deg C2=4+-0.3deg R01=0/4load R02=4/4load

----------

L=1.5+-0.2mm N3=800r/min C3=(4deg) t1=2--sec. t2=2--sec.

----------

N1=1200++r/min N2=1400r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=2.5--deg C2=4+-0.3deg R01=0/4load R02=4/4load

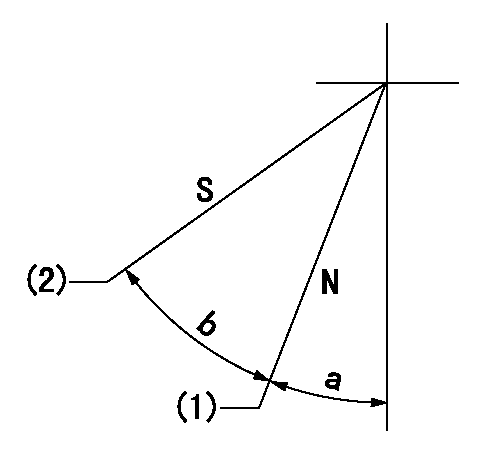

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=16mm bb=1mm

----------

a=30deg+-5deg b=29deg+-5deg

----------

aa=16mm bb=1mm

----------

a=30deg+-5deg b=29deg+-5deg

0000000901

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Stop lever angle

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 15 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

Information:

The primary fuel filter should be cleaned, and the secondary (main) fuel filter element replaced, as follows: 1. When the fuel pressure gauge (if equipped) indicates low fuel pressure.2. When the engine has a noticable loss of power.3. Every 500 service hours of operation if the engine is not equipped with a fuel pressure gauge.

Fuel leaked or spilled onto hot surfaces or electrical components can cause a fire. Disconnect the battery (turn disconnect switch OFF) when changing fuel filters.

Do not fill fuel filters with fuel before installing them. Contaminated fuel will cause accelerated wear to fuel system parts.

Close the fuel supply valve at the tank before servicing filters. Open the valve after filter servicing is completed.Cleaning Primary Filter

Use all cleaning solutions with care.

1. Loosen the nut (1) on the filter cover and lower the filter case (3).2. Remove the element (2). Wash the cover and element in clean nonflammable solvent.3. Reinstall the element.4. Install the element and case onto the cover into the case.5. Tighten the bolt.Changing Secondary Filter

1. Unscrew filter element. Throw away the used element. 2. Make certain all of the used element seal is cleaned from the filter base. 3. Coat the seal of the new element with clean diesel fuel.4. Install the filter by hand. When the seal contacts the base, tighten 3/4 turn more.There are rotation marks 90° apart on the filter. Use these as a guide for proper tightening.5. Start the engine and check for leaks. If the engine will not start, prime the fuel system.

Fuel leaked or spilled onto hot surfaces or electrical components can cause a fire. Disconnect the battery (turn disconnect switch OFF) when changing fuel filters.

Do not fill fuel filters with fuel before installing them. Contaminated fuel will cause accelerated wear to fuel system parts.

Close the fuel supply valve at the tank before servicing filters. Open the valve after filter servicing is completed.Cleaning Primary Filter

Use all cleaning solutions with care.

1. Loosen the nut (1) on the filter cover and lower the filter case (3).2. Remove the element (2). Wash the cover and element in clean nonflammable solvent.3. Reinstall the element.4. Install the element and case onto the cover into the case.5. Tighten the bolt.Changing Secondary Filter

1. Unscrew filter element. Throw away the used element. 2. Make certain all of the used element seal is cleaned from the filter base. 3. Coat the seal of the new element with clean diesel fuel.4. Install the filter by hand. When the seal contacts the base, tighten 3/4 turn more.There are rotation marks 90° apart on the filter. Use these as a guide for proper tightening.5. Start the engine and check for leaks. If the engine will not start, prime the fuel system.