Information injection-pump assembly

ZEXEL

101691-9621

1016919621

NISSAN-DIESEL

1671395072

1671395072

Rating:

Cross reference number

ZEXEL

101691-9621

1016919621

NISSAN-DIESEL

1671395072

1671395072

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.7

3.65

3.75

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

13.6

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

106.4

104.8

108

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

9.9+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

9

7.2

10.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.6)

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

106.4

105.4

107.4

Basic

*

Fixing the lever

*

Boost pressure

kPa

29.3

29.3

Boost pressure

mmHg

220

220

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.1

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

96.7

93.5

99.9

Fixing the lever

*

Boost pressure

kPa

29.3

29.3

Boost pressure

mmHg

220

220

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2(12.7)

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

62.9

61.9

63.9

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

I

Rack position

14.8+-0.

5

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

80

80

100

Fixing the lever

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

400

400

400

Rack position

R2(12.7)

Boost pressure

kPa

4

2.7

5.3

Boost pressure

mmHg

30

20

40

Boost compensator adjustment_02

Pump speed

r/min

400

400

400

Rack position

R1-0.5

Boost pressure

kPa

9.3

8

10.6

Boost pressure

mmHg

70

60

80

Boost compensator adjustment_03

Pump speed

r/min

400

400

400

Rack position

R1+0.1

Boost pressure

kPa

16

16

16

Boost pressure

mmHg

120

120

120

Timer adjustment

Pump speed

r/min

920--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

870

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

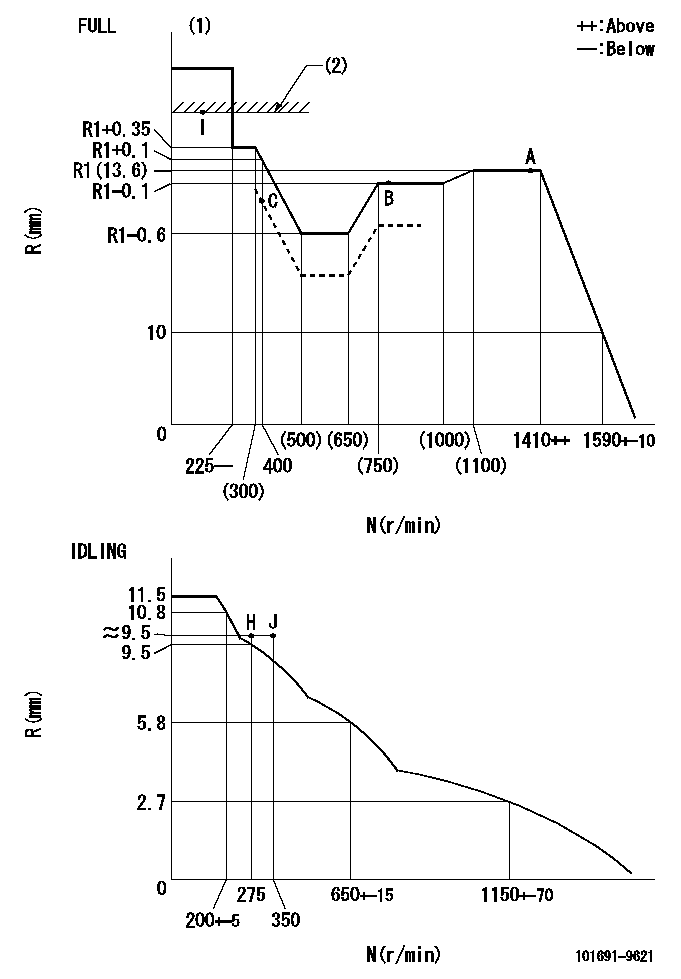

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=B36

----------

----------

T1=B36

----------

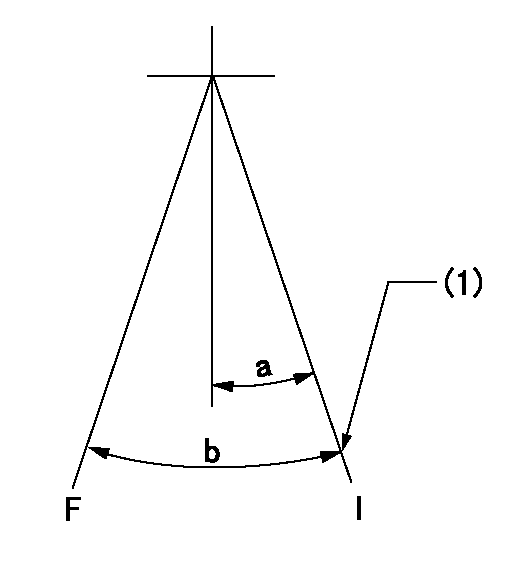

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=26.5deg+-5deg b=43deg+-3deg

----------

----------

a=26.5deg+-5deg b=43deg+-3deg

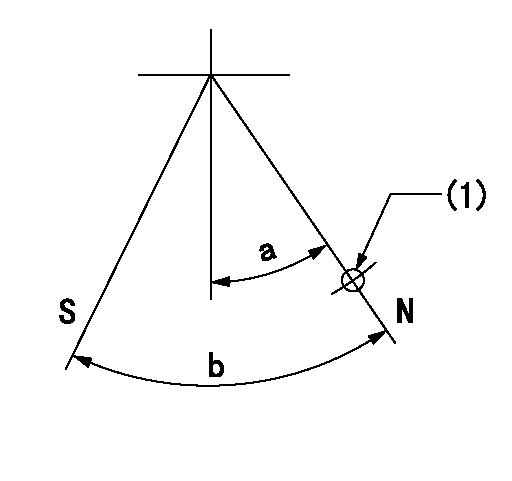

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

----------

aa=36mm

----------

a=20deg+-5deg b=40deg+-5deg

----------

aa=36mm

----------

a=20deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Flywheel And/Or Front Power Take-Off Clutches

Checking Clutch Adjustment

While engaging the clutch to pick up the load, check the clutch adjustment. The clutch should engage with a hard push and distinct snap. If engagement is "soft", adjust the clutch.Adjusting Clutch Engagement

1. Stop the engine and remove the clutch inspection cover. 2. Turn the clutch until the lock pin, engaged in the locking ring, is visible.3. Pull the lock pin out and rotate the locking ring clockwise until the lock pin pops into the next notch. 4. Test the clutch adjustment. If still too "soft", rotate the ring to the next notch. If the adjustment is too tight-turn the ring back one notch.5. Install the cover.Generator Set

Your electric set engine may be equipped with a Caterpillar SR4 Generator. The SR4 Generator is a brushless design, and therefore requires no periodic maintenance other than lubrication of the rear bearing. See Lubrication Instructions.The generator serial number is stamped on the generator housing. The first group of numbers, reading from the left, indicates the frame size. Following this number are the letters BS, BH or BG. The letter B indicates the generator is of the SR4 design. The letter S, H or G indicates the voltage rating of the generator. The following numerical digits are the serial number of the generator in that particular frame size and voltage rating. A complete explanation of the numbers and letters in the serial number are found in the GENERATOR SET SYSTEMS OPERATION SECTION. Always use the complete serial number in your communications with your Caterpillar dealer.If you have a generator of other than Caterpillar design, see the Manufacturer's Instructions.

GENERATOR SERIAL NUMBER LOCATION

Checking Clutch Adjustment

While engaging the clutch to pick up the load, check the clutch adjustment. The clutch should engage with a hard push and distinct snap. If engagement is "soft", adjust the clutch.Adjusting Clutch Engagement

1. Stop the engine and remove the clutch inspection cover. 2. Turn the clutch until the lock pin, engaged in the locking ring, is visible.3. Pull the lock pin out and rotate the locking ring clockwise until the lock pin pops into the next notch. 4. Test the clutch adjustment. If still too "soft", rotate the ring to the next notch. If the adjustment is too tight-turn the ring back one notch.5. Install the cover.Generator Set

Your electric set engine may be equipped with a Caterpillar SR4 Generator. The SR4 Generator is a brushless design, and therefore requires no periodic maintenance other than lubrication of the rear bearing. See Lubrication Instructions.The generator serial number is stamped on the generator housing. The first group of numbers, reading from the left, indicates the frame size. Following this number are the letters BS, BH or BG. The letter B indicates the generator is of the SR4 design. The letter S, H or G indicates the voltage rating of the generator. The following numerical digits are the serial number of the generator in that particular frame size and voltage rating. A complete explanation of the numbers and letters in the serial number are found in the GENERATOR SET SYSTEMS OPERATION SECTION. Always use the complete serial number in your communications with your Caterpillar dealer.If you have a generator of other than Caterpillar design, see the Manufacturer's Instructions.

GENERATOR SERIAL NUMBER LOCATION