Information injection-pump assembly

ZEXEL

101691-9060

1016919060

NISSAN-DIESEL

16700Z5507

16700z5507

Rating:

Service parts 101691-9060 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-Z5506

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Include in #1:

101691-9060

as INJECTION-PUMP ASSEMBLY

Include in #2:

104745-8420

as _

Cross reference number

ZEXEL

101691-9060

1016919060

NISSAN-DIESEL

16700Z5507

16700z5507

Zexel num

Bosch num

Firm num

Name

101691-9060

16700Z5507 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FD6 * K

FD6 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.4

2.35

2.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

C

Rack position

9.7

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

55

53.4

56.6

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

D

Rack position

8.2+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8.9

7.1

10.7

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

E

Rack position

13.7+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

78

72

98

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

650+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

2.2

1.7

2.7

Timer adjustment_03

Pump speed

r/min

1600

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

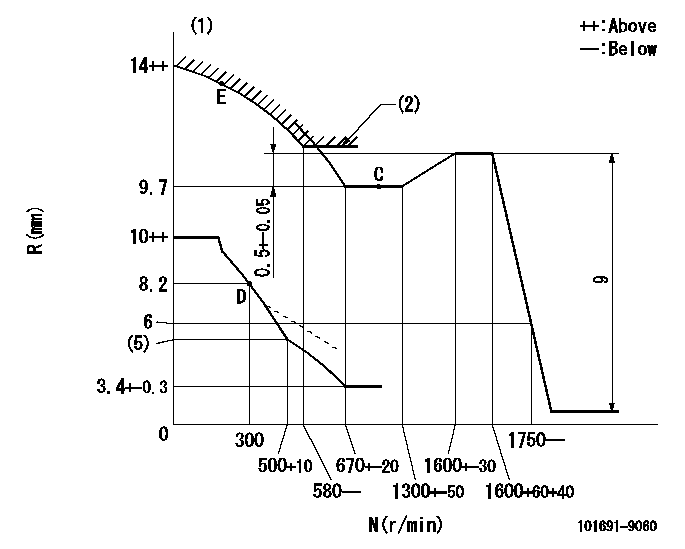

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Excess fuel setting for starting: SXL

----------

DL=6.7-0.2mm SXL=10.2+0.2mm

----------

----------

DL=6.7-0.2mm SXL=10.2+0.2mm

----------

0000000901

F:Full load

I:Idle

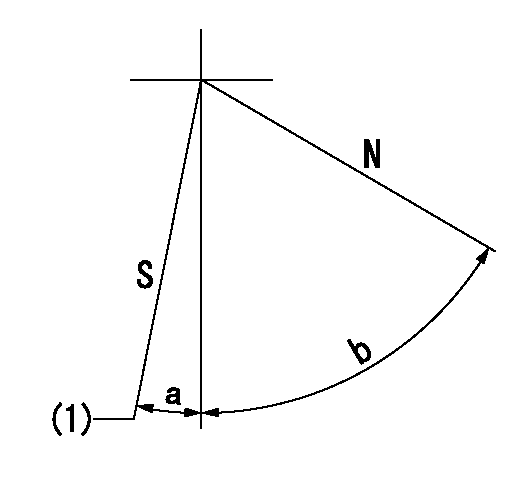

(1)Stopper bolt setting

----------

----------

a=15deg+-5deg b=25deg+-3deg

----------

----------

a=15deg+-5deg b=25deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

----------

aa=0mm

----------

a=12deg+-5deg b=60deg+-5deg

----------

aa=0mm

----------

a=12deg+-5deg b=60deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'P' at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Start By:a. remove automatic timing advance unit

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

Before any timing gears are removed, make sure "C" on the crankshaft gear is in alignment with "C" mark on the camshaft gear. 1. Remove bolts, plate (1) and fuel pump idler gear (2). 2. Remove bearing from idler gear (2) with tool (A). 3. Remove four bolts (3) and camshaft gear (4). 4. Remove bolts that are used to fasten shield (5) in position between the fuel pump and the exhaust manifold. Slide shield back from the timing cover plate.5. Remove the three nuts (6). 6. Remove six bolts (7). Remove the timing gear plate and the gasket. The following steps are to install the timing gears and plate.7. Clean the old gasket from the contact surfaces of the timing gear plate and cylinder block. Install a new gasket on the cylinder block. Cut the gasket even with the bottom face of the cylinder block.8. Be sure the O-ring seals are in position on the end of the fuel injection pump housing. Put the timing gear plate in position on the cylinder block and install the six bolts (7). Install nuts (6).

After the timing gear plate is installed, be sure the rack is free to move in the fuel injection pump housing. The O-ring seal on the drive end of the fuel injection pump housing can hold the rack and prevent free rack movement. Rack movement can be seen through hole in the timing gear plate just above where the fuel pump gear is mounted. If the rack does not move freely, remove the timing gear plate and check the O-ring seal on the drive end of the fuel injection pump housing. If the rack does not move freely, the engine can over speed and be damaged. Serious personal injury can be the result.

9. Install camshaft gear (4) with the "C" mark on the camshaft gear in alignment with the "C" mark on the crankshaft gear as shown in the illustration in the Specification section of this manual. Tighten the volts to a torque of 55 7 N m (41 5 lb ft).10. Use tooling (A) to install the bearing in idler gear (2). The end of the bearing must be 1.52 .025 mm (.060 .010 in) below the face of the gear hub.11. Be sure the oil hole in the shaft for gear (2) is open. Install idler gear (2). Put the plate on position with the finished side toward gear (2) and install the bolts.12. Install shield (5) and the four bolts.End By:a. install automatic timing advance unit

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

Before any timing gears are removed, make sure "C" on the crankshaft gear is in alignment with "C" mark on the camshaft gear. 1. Remove bolts, plate (1) and fuel pump idler gear (2). 2. Remove bearing from idler gear (2) with tool (A). 3. Remove four bolts (3) and camshaft gear (4). 4. Remove bolts that are used to fasten shield (5) in position between the fuel pump and the exhaust manifold. Slide shield back from the timing cover plate.5. Remove the three nuts (6). 6. Remove six bolts (7). Remove the timing gear plate and the gasket. The following steps are to install the timing gears and plate.7. Clean the old gasket from the contact surfaces of the timing gear plate and cylinder block. Install a new gasket on the cylinder block. Cut the gasket even with the bottom face of the cylinder block.8. Be sure the O-ring seals are in position on the end of the fuel injection pump housing. Put the timing gear plate in position on the cylinder block and install the six bolts (7). Install nuts (6).

After the timing gear plate is installed, be sure the rack is free to move in the fuel injection pump housing. The O-ring seal on the drive end of the fuel injection pump housing can hold the rack and prevent free rack movement. Rack movement can be seen through hole in the timing gear plate just above where the fuel pump gear is mounted. If the rack does not move freely, remove the timing gear plate and check the O-ring seal on the drive end of the fuel injection pump housing. If the rack does not move freely, the engine can over speed and be damaged. Serious personal injury can be the result.

9. Install camshaft gear (4) with the "C" mark on the camshaft gear in alignment with the "C" mark on the crankshaft gear as shown in the illustration in the Specification section of this manual. Tighten the volts to a torque of 55 7 N m (41 5 lb ft).10. Use tooling (A) to install the bearing in idler gear (2). The end of the bearing must be 1.52 .025 mm (.060 .010 in) below the face of the gear hub.11. Be sure the oil hole in the shaft for gear (2) is open. Install idler gear (2). Put the plate on position with the finished side toward gear (2) and install the bolts.12. Install shield (5) and the four bolts.End By:a. install automatic timing advance unit

Have questions with 101691-9060?

Group cross 101691-9060 ZEXEL

Nissan-Diesel

101691-9060

16700Z5507

INJECTION-PUMP ASSEMBLY

FD6

FD6