Information injection-pump assembly

BOSCH

9 400 615 972

9400615972

ZEXEL

101691-1850

1016911850

MITSUBISHI

ME018147

me018147

Rating:

Service parts 101691-1850 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME016540

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Include in #1:

101691-1850

as INJECTION-PUMP ASSEMBLY

Include in #2:

104745-3550

as _

Cross reference number

BOSCH

9 400 615 972

9400615972

ZEXEL

101691-1850

1016911850

MITSUBISHI

ME018147

me018147

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.5

3.45

3.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.9

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

75.6

74.6

76.6

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.4+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

7.5

6.2

8.8

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

66

66

71

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1270--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

1.5

1

2

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

3

3

3

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

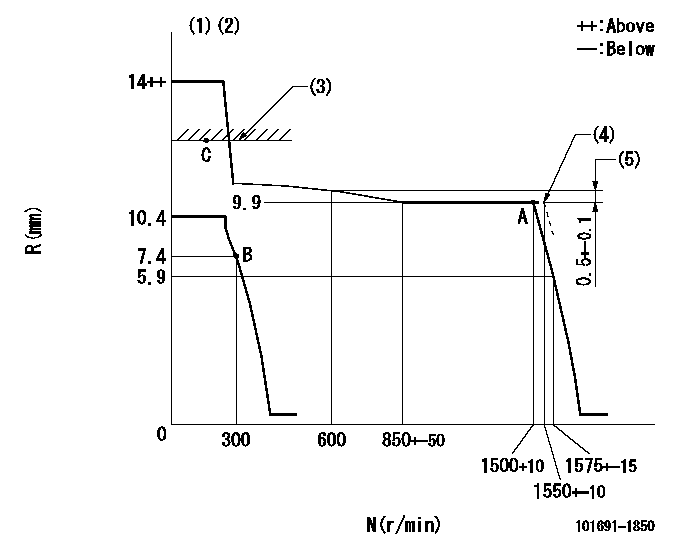

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Supplied with torque spring not set.

(3)RACK LIMIT

(4)Setting at shipping

(5)Rack difference between N = N1 and N = N2

----------

K=8 N1=1500r/min N2=600r/min

----------

----------

K=8 N1=1500r/min N2=600r/min

----------

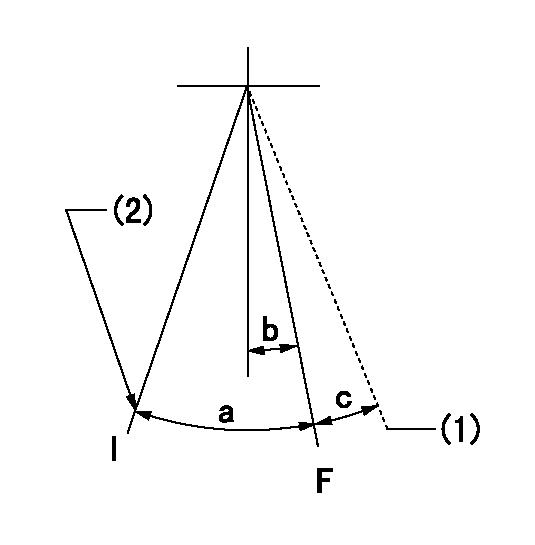

Speed control lever angle

F:Full speed

I:Idle

(1)At shipping

(2)Stopper bolt setting

----------

----------

a=29deg+-5deg b=4deg+-5deg c=(2deg)

----------

----------

a=29deg+-5deg b=4deg+-5deg c=(2deg)

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '3' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(130deg)

----------

aa=16deg

----------

a=(130deg)

Information:

Measure wear of the cylinder bore at the top and bottom of piston ring travel.(1) Cylinder bore [standard, original size] ... 114.300 to 114.338 mm (4.5000 to 4.5015 in) The recommendation is made to make the cylinder bore the next size larger when the size of the bore is ... 114.452 mm (4.5060 in)Cylinder bore must be made the next size larger when the size of the bore is ... 114.529 mm (4.5090 in)Cylinder bore [0.51 mm (.020 in) larger than the original size] ... 114.821 0.013 mm (4.5205 .0005 in)The recommendation is made to make the cylinder bore the next size larger when the size of the bore is ... 114.960 mm (4.5260 in)Cylinder bore must be made the next size larger when the size of the bore is ... 115.037 mm (4.5290 in)Cylinder bore [1.02 mm (.040 in) larger than the original size] ... 115.329 0.013 mm (4.5405 .0005 in)Maximum permissible wear of cylinder bores (replacement of the cylinder block is necessary) ... 115.545 mm (4.5490 in)(2) Bore in block for camshaft bearing ... 67.374 0.013 mm (2.6525 .0005 in) Install camshaft bearings with the oil hole toward the top of the cylinder block.(3) Width of main bearing cap ... 166.624 0.018 mm (6.5600 .0007 in) Minimum permissible width of main bearing cap ... 166.573 mm (6.5580 in)Width of main bearing cap guide (in cylinder block) ... 166.599 0.013 mm (6.5590 .0005 in)(4) Bore in block for main bearing ... 94.171 0.013 mm (3.7075 .0005 in) Permissible amount of distortion in bore ... 94.13 to 94.21 mm (3.706 to 3.709 in) (5) Torque for bolts holding caps for main bearings: a. Put 2P2506 Thread Lubricant on bolt threads and washer face.b. Tighten all bolts in number sequence to ... 40 4 N m (30 3 lb ft)c. Put a mark on each bolt and cap.d. Tighten all bolts in number sequence from mark ... 120 5° (6) Dimension (new) from centerline of crankshaft bearing bore to bottom of block (pan rails) ... 95.250 0.038 mm (3.7500 .0015 in)(7) Dimension (new) from centerline of crankshaft bearing bore to top of block (top deck) ... 322.66 0.13 mm (12.703 .005 in)

There are holes in the bores for the main bearings, between the cylinders for piston cooling orifices. These holes must have orifices or plugs installed or low oil pressure will be the result.

If the base for the oil cooler is 357.2 mm (14.06 in) long the engine has piston cooling orifices installed. If the base for the oil cooler is 268.2 mm (10.56 in) long the engine has plugs installed.Piston cooling orifices were eliminated from 3208 truck engines effective with truck engine 2Z30692 with a rating of 150 KW (200 hp) @ 2000 rpm or 160 KW (215 hp) @ 2200 rpm. On earlier engines

There are holes in the bores for the main bearings, between the cylinders for piston cooling orifices. These holes must have orifices or plugs installed or low oil pressure will be the result.

If the base for the oil cooler is 357.2 mm (14.06 in) long the engine has piston cooling orifices installed. If the base for the oil cooler is 268.2 mm (10.56 in) long the engine has plugs installed.Piston cooling orifices were eliminated from 3208 truck engines effective with truck engine 2Z30692 with a rating of 150 KW (200 hp) @ 2000 rpm or 160 KW (215 hp) @ 2200 rpm. On earlier engines