Information injection-pump assembly

BOSCH

9 400 615 971

9400615971

ZEXEL

101691-1841

1016911841

MITSUBISHI

ME018181

me018181

Rating:

Service parts 101691-1841 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME790067

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

101691-1841

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 615 971

9400615971

ZEXEL

101691-1841

1016911841

MITSUBISHI

ME018181

me018181

Zexel num

Bosch num

Firm num

Name

9 400 615 971

ME018181 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D31 K 14BE INJECTION PUMP ASSY PE6A PE

6D31 K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.5

3.45

3.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

7.9

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

42.9

41.9

43.9

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.4+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

7.5

6.2

8.8

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

66

66

71

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1600

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

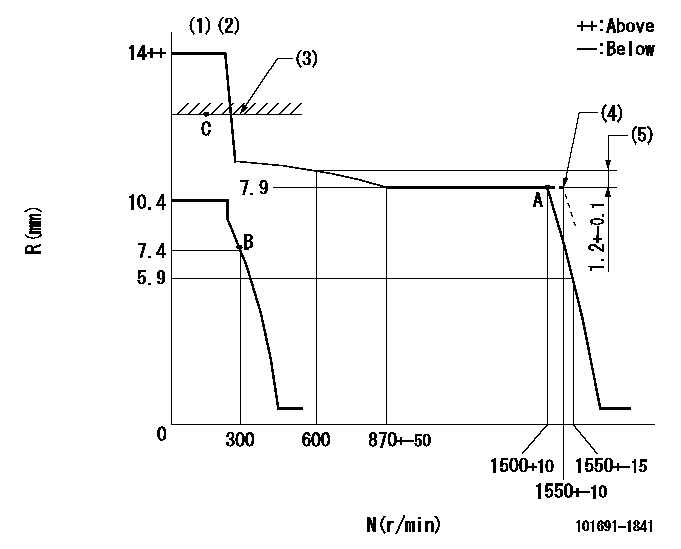

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Supplied with torque spring not set.

(3)RACK LIMIT

(4)Setting at shipping

(5)Rack difference between N = N1 and N = N2

----------

K=9 N1=1500r/min N2=600r/min

----------

----------

K=9 N1=1500r/min N2=600r/min

----------

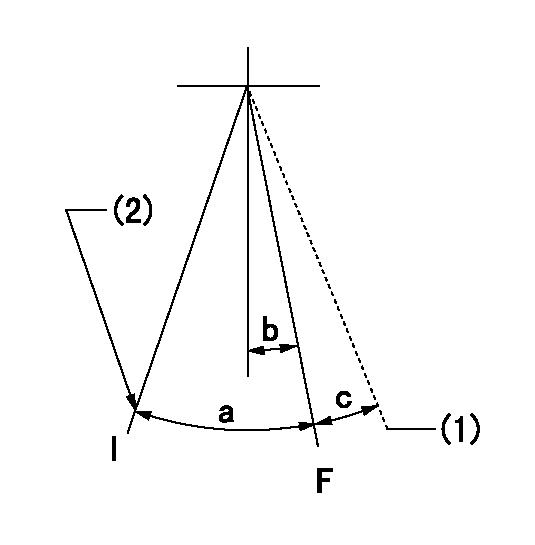

Speed control lever angle

F:Full speed

I:Idle

(1)At shipping

(2)Stopper bolt setting

----------

----------

a=28deg+-5deg b=7deg+-5deg c=(2deg)

----------

----------

a=28deg+-5deg b=7deg+-5deg c=(2deg)

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '3' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=18deg

----------

a=(140deg)

----------

aa=18deg

----------

a=(140deg)

Information:

Table 1

Required Parts

Callout Part Number Description Qty

1 7E-3870 Muffler Clamp 1

2 309-3554 Diesel Particulate Filter Group 1

3 309-3592 Clamp Assembly 1

4 309-3864 Tube 1

5 122-4026 Spacer 4

6 7X-0605 Hard Washer 6

7 8T-4244 Nut 2

8 8T-4910 Bolt 4

9 271-6537 Exhaust Monitor Group 1

10 216-7990 Installation Assembly 1

11 282-0031 Remote Display 1

12 220-3778 Adapter Cable Assembly (INTERFACE) 1 Parts Location

Illustration 2 g01549193

(1) 7E-3870 Muffler Clamp (2) 309-3554 Diesel Particulate Filter Group (3) 309-3592 Clamp Assembly (4) 309-3864 Tube (5) 122-4026 Spacer (6) 7X-0605 Hard Washer (7) 8T-4244 Nut (8) 8T-4910 Bolt Installation Procedure

You must read and thoroughly understand the guidelines in Special Instruction, REHS1807, "Installation Guide for Particulate Trap Exhaust Filters" before you attempt any part of the following installation procedure.The installation procedure that follows is specific for the listed machines.Diesel Particulate Filter Installation

Remove the existing muffler.

Illustration 3 g01457287

(A) Flared end (1) 7E-3870 Muffler Clamp (4) 309-3864 Tube

Install 309-3864 Tube (4) by attaching flared end (A) to the turbocharger. Leave 7E-3870 Muffler Clamp (1) loosely attached on the other end of tube (4) .

Illustration 4 g01457295

(3) 309-3592 Clamp Assembly (Lower half) (5) 122-4026 Spacer (6) 7X-0605 Hard Washer (8) 8T-4910 Bolt

Remove the two bolts, two hard washers, two lock washers, and two nuts from 309-3592 Clamp Assembly (3). Keep these parts together with the upper half of the clamp assembly. These parts will be reinstalled in Step 8.

Install the lower half of 309-3592 Clamp Assembly (3) to the existing bracket near the turbocharger by using two 8T-4910 Bolts (8), two 7X-0605 Hard Washers (6), and two 122-4026 Spacers (5). Refer to Illustration 4.

Illustration 5 g01457434

(1) 7E-3870 Muffler Clamp (2) 309-3554 Diesel Particulate Filter Group (4) 309-3864 Tube (5) 122-4026 Spacer (6) 7X-0605 Hard Washer (7) 8T-4244 Nut (8) 8T-4910 Bolt

Install 309-3554 Diesel Particulate Filter Group (2) by inserting the inlet tube of the diesel particulate filter over 309-3864 Tube (4). The weight of the diesel particulate filter group is approximately 40 kg (88 lb).

Secure the diesel particulate filter to the other bracket on the engine block by using two 8T-4910 Bolts (8), two 8T-4244 Nuts (7), two 122-4026 Spacers (5), and four 7X-0605 Hard Washers (6) .

Tighten 7E-3870 Muffler Clamp (1) over the inlet tube of the diesel particulate filter