Information injection-pump assembly

ZEXEL

101691-0990

1016910990

ISUZU

1156000610

1156000610

Rating:

Service parts 101691-0990 INJECTION-PUMP ASSEMBLY:

1.

_

4.

SUPPLY PUMP

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

9-15300-184-2

12.

Open Pre:MPa(Kqf/cm2)

9.8{100}

15.

NOZZLE SET

Include in #1:

101691-0990

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

101691-0990

1016910990

ISUZU

1156000610

1156000610

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle holder

105031-2480

Bosch type code

KB69SD273NP6

Opening pressure

MPa

9.8

Opening pressure

kgf/cm2

100

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.2

2.15

2.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

13

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

117.5

115.2

119.8

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

13

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

124

120.3

127.7

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

6.5+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

17.5

15.2

19.8

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Timer adjustment

Pump speed

r/min

400+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

600

Advance angle

deg.

0.6

0.1

1.1

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

1.4

0.9

1.9

Timer adjustment_04

Pump speed

r/min

1150

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

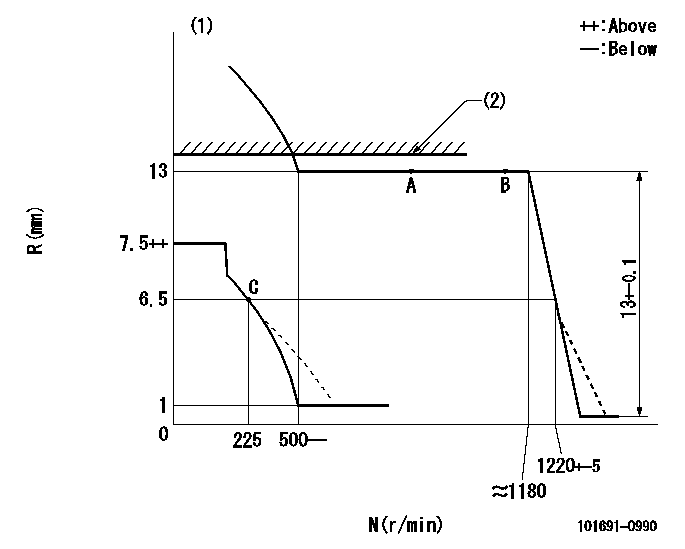

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)RACK LIMIT: RAL

----------

DL=6-0.2mm RAL=13+0.2mm

----------

----------

DL=6-0.2mm RAL=13+0.2mm

----------

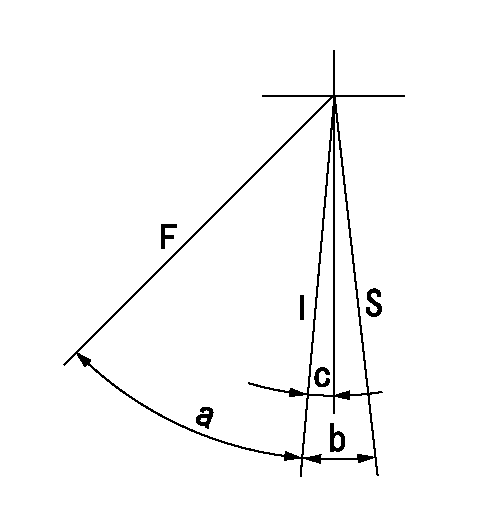

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=46deg+-2deg b=9deg+-2deg c=4deg+-5deg

----------

----------

a=46deg+-2deg b=9deg+-2deg c=4deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=275r/min Ra=6.5mm

----------

----------

N1=275r/min Ra=6.5mm

----------

Information:

ROCKER ARM SHAFT ASSEMBLY

1. Fuel return line (one each head). 2. Bolts and locks (four each head).4. Remove rocker arm shaft assembly (3). Remove push rods (4).

REMOVING ROCKER ARM SHAFT ASSEMBLY

3. Rocker arm shaft assembly (one each head). 4. Push rods (eight each head).Install Rocker Arm Shaft Assemblies

1. Lubricate the cam followers, push rods, and rocker arm shaft assembly with clean engine oil (SAE 30).2. Install push rods. Position the rocker arm shaft assembly on the cylinder head.3. Install the rocker arm shaft assembly retaining bolts and locks. Tighten bolts to 18 5 lb. ft. (2.5 0.7 mkg) and bend the locks.4. Install the fuel return line.5. Adjust the intake valve clearance to .015 in. (0.38 mm) and the exhaust valve clearance to .025 in. (0.64 mm).6. Install valve cover. Install valve cover retaining bolts and tighten bolts to 120 24 lb. in. (138 28 cm.kg).Disassemble Rocker Arm Shaft Assembly

1. Remove retaining bolts and locks from each end of rocker arm shaft assembly and disassemble the rocker arm shaft assembly.

ROCKER ARM SHAFT ASSEMBLY DISASSEMBLED

1. Rocker arm shaft. 2. Rivet. 3. Washers (eight). 4. Rocker arms (two per cylinder). 5. Adjusting screw. 6. Bracket. 7. Oil supply hole.Assemble Rocker Arm Shaft Assembly

1. The oil holes in shaft (1), arms (4) and bracket (6) must be clean and free of dirt or foreign material.2. Install adjusting screws (5) into rocker arms (4) so they extend .44 in. (11.2 mm) below arm. This will avoid forcing valves into piston crowns when rocker arm assembly is installed on cylinder head.

ROCKER ARM SHAFT ASSEMBLY

1. Rocker arm shaft. 2. Rivet. 3. Washers (eight). 4. Rocker arms (two per cylinder). 5. Adjusting screw. 6. Bracket. 7. Oil supply hole.3. Install arms (4) on shaft with washers (3) positioned as shown.4. Position shaft (1) and arms (4) into bracket (6) so screws (5) are on the same side of bracket (6) as oil supply hole (7). Rivet (2) must be on top when shaft (1) is positioned into bracket (6). Later rocker arm shaft assemblies have machined flats (8). The machined flats must be on top when shaft (1) is positioned into bracket (6).

LATER ROCKER ARM SHAFT ASSEMBLY

1. Rocker arm shaft. 6. Bracket. 8. Machined flats (four per shaft).