Information injection-pump assembly

BOSCH

F 019 Z20 481

f019z20481

ZEXEL

101685-0570

1016850570

ISUZU

1156000362

1156000362

Rating:

Service parts 101685-0570 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

9-15300-184-2

12.

Open Pre:MPa(Kqf/cm2)

9.8{100}

15.

NOZZLE SET

Include in #1:

101685-0570

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 019 Z20 481

f019z20481

ZEXEL

101685-0570

1016850570

ISUZU

1156000362

1156000362

Zexel num

Bosch num

Firm num

Name

101685-0570

F 019 Z20 481

1156000362 ISUZU

INJECTION-PUMP ASSEMBLY

DA120 * K 14BE PE6A PE

DA120 * K 14BE PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.2

2.15

2.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

13.5

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

63

61.6

64.4

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

13

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

63.3

61.1

65.5

Max. variation between cylinders

%

0

-3

3

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

11.5

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

38.7

36.8

40.6

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

10+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

15

12.7

17.3

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Test data Ex:

Governor adjustment

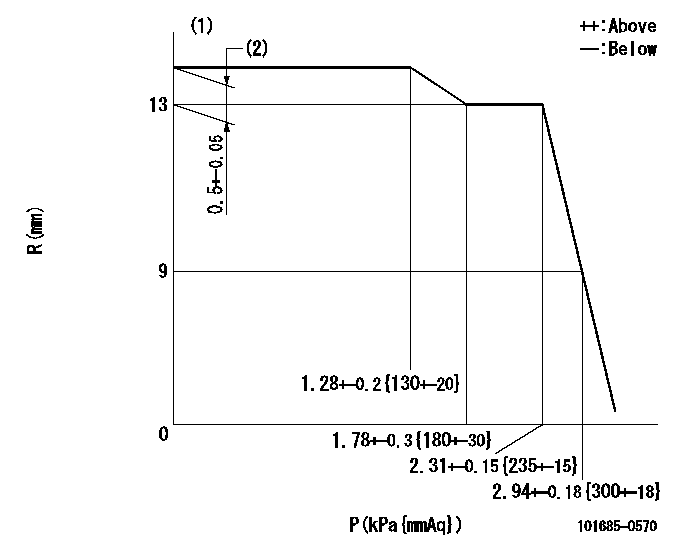

R:Rack position (mm)

P:Negative pressure

(1)Pneumatic governor

(2)Torque control stroke

----------

----------

----------

----------

Information:

This troubleshooting guide, when followed exactly as shown, can be an aid for the serviceman to find the cause of existing problems. The information from the measurements will also show proof if there is any basis for the complaint.Be sure to get a good description of the problem from the operator and/or the person who owns the vehicle. What they tell you about the problem can save you time and make the repair job faster and easier.Low Power And High Fuel Consumption Problems

The troubleshooting charts that follow provide a definite sequence to be followed for a logical, one by one elimination of many variables. The encircled numbers do not designate steps, but are references to detailed instructions that can not be shown on the chart. Always read the written material that corresponds with the encircled numbers on the charts.The PRIMARY ENGINE TESTS consist of quick and easy procedures that could identify the problem with a minimum loss of time. Always make these tests before starting the more involved troubleshooting charts.The necessary instruments to check each problem in sequence are shown on the chart. If the correct instrument is not available for the test, do not continue. The vehicle must be sent to a shop where the necessary tools are available.Whenever a problem is found and corrected, always run the test again to that point to be sure there is not a combination of problems. When the problem has been corrected and the complaint resolved, stop the test. Do not continue through the complete procedure just because it is there.When investigating possible causes, follow the letter sequence shown. Possible causes are arranged in order from more probable/easiest to check to less probable-/more complex to check. OTHER PROBLEMS: VEHICLE OR VEHICLE OPERATION, MISFIRING AND RUNNING ROUGH, TOO MUCH EXHAUST SMOKE, DIFFICULT STARTING, COOLING SYSTEM, LOSS OF COOLANT, OR FUEL IN CRANKCASE OIL.The probable causes of a problem are given in the order they most commonly take place. Check the probable causes in the same order that they are given. When troubleshooting, use the section on recommended procedures which follow each chart to check and make the necessary corrections for each probable cause.Engine Vibration Problem

The troubleshooting chart provides a definite sequence to be followed for a logical procedure to determine the frequency and amplitude of vibration so that the source of the vibration can be located and corrected.

The troubleshooting charts that follow provide a definite sequence to be followed for a logical, one by one elimination of many variables. The encircled numbers do not designate steps, but are references to detailed instructions that can not be shown on the chart. Always read the written material that corresponds with the encircled numbers on the charts.The PRIMARY ENGINE TESTS consist of quick and easy procedures that could identify the problem with a minimum loss of time. Always make these tests before starting the more involved troubleshooting charts.The necessary instruments to check each problem in sequence are shown on the chart. If the correct instrument is not available for the test, do not continue. The vehicle must be sent to a shop where the necessary tools are available.Whenever a problem is found and corrected, always run the test again to that point to be sure there is not a combination of problems. When the problem has been corrected and the complaint resolved, stop the test. Do not continue through the complete procedure just because it is there.When investigating possible causes, follow the letter sequence shown. Possible causes are arranged in order from more probable/easiest to check to less probable-/more complex to check. OTHER PROBLEMS: VEHICLE OR VEHICLE OPERATION, MISFIRING AND RUNNING ROUGH, TOO MUCH EXHAUST SMOKE, DIFFICULT STARTING, COOLING SYSTEM, LOSS OF COOLANT, OR FUEL IN CRANKCASE OIL.The probable causes of a problem are given in the order they most commonly take place. Check the probable causes in the same order that they are given. When troubleshooting, use the section on recommended procedures which follow each chart to check and make the necessary corrections for each probable cause.Engine Vibration Problem

The troubleshooting chart provides a definite sequence to be followed for a logical procedure to determine the frequency and amplitude of vibration so that the source of the vibration can be located and corrected.

Have questions with 101685-0570?

Group cross 101685-0570 ZEXEL

Isuzu

101685-0570

F 019 Z20 481

1156000362

INJECTION-PUMP ASSEMBLY

DA120

DA120