Information injection-pump assembly

BOSCH

9 400 610 785

9400610785

ZEXEL

101681-9600

1016819600

NISSAN-DIESEL

16712Z5510

16712z5510

Rating:

Service parts 101681-9600 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-Z5508

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

101681-9600

as INJECTION-PUMP ASSEMBLY

Include in #2:

104745-3320

as _

Cross reference number

BOSCH

9 400 610 785

9400610785

ZEXEL

101681-9600

1016819600

NISSAN-DIESEL

16712Z5510

16712z5510

Zexel num

Bosch num

Firm num

Name

101681-9600

9 400 610 785

16712Z5510 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FD6T07 * K

FD6T07 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.4

2.35

2.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.5

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

59

58

60

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

14.6

13.5

15.7

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

13.9+-0.

1

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

115

105

125

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

600

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.6

0.1

1.1

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

3

2.5

3.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

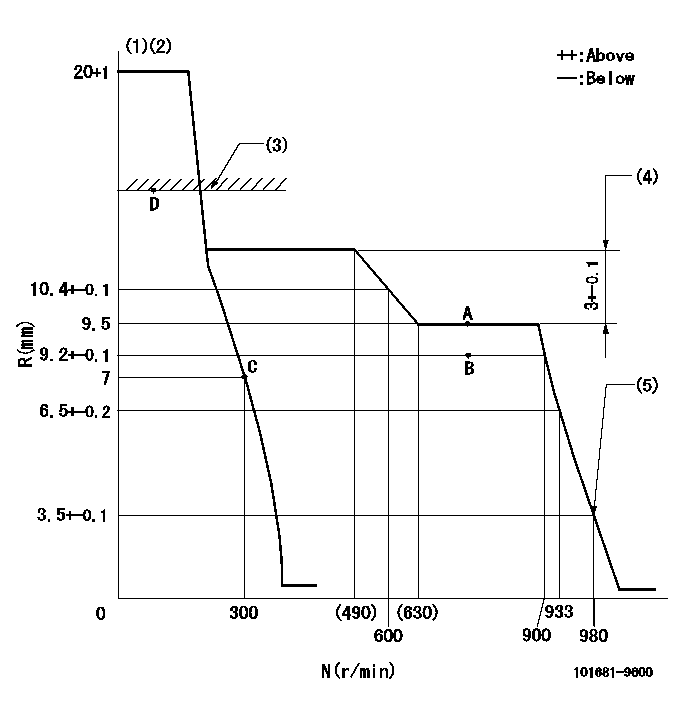

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Rack difference between N = N1 and N = N2

(5)Set idle sub-spring

----------

K=17 N1=750r/min N2=450r/min

----------

----------

K=17 N1=750r/min N2=450r/min

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=25deg+-5deg

----------

----------

a=10deg+-5deg b=25deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

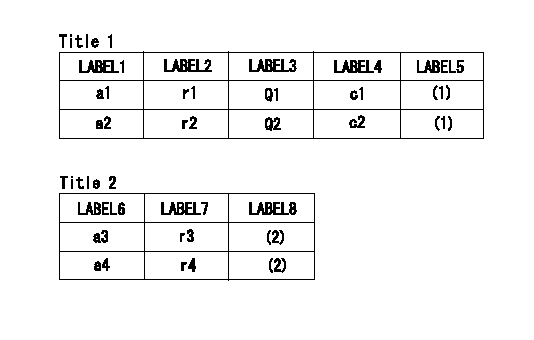

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)-

----------

----------

a1=B a2=E r1=750r/min r2=750r/min Q1=59+-1mm3/st Q2=- c1=+-2.5% c2=+-2.5% a3=18 a4=- r3=900r/min r4=-

----------

----------

a1=B a2=E r1=750r/min r2=750r/min Q1=59+-1mm3/st Q2=- c1=+-2.5% c2=+-2.5% a3=18 a4=- r3=900r/min r4=-

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'P' at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Crankcase Lubricating Oil

The Lubrication and Maintenance Charts list the normal oil change periods as determined by fuel sulphur content. (Make an initial oil change after the first 500 miles of operation for reconditioned engines.)Use oils which meet Engine Service classification CD or MIL-L-2104C. These are additive-type oils that have been approved for use in Caterpillar Diesel Engines. Diesel Engine Crankcase

Check oil level daily before starting engine and when refueling. Check with the engine either running or stopped as indicated on the oil level gauge. Add oil when the level drops to the add oil mark. Drain the crankcase every 10,000 miles while engine is warm and stopped. If equipped with a 13 qt. supplemental filter system the normal interval can be extended to 15,000 miles. Install drain plug. Diesel Engine Crankcase Lubricating Oil Filter

Change filter element every 10,000 miles. Drain the filter housing by removing drain plug. Loosen bolt on the cover and remove the housing and filter element. Inspect seal and install a new one if necessary. Wash the inside of the filter housing and install a new Caterpillar filter element. After draining crankcase remove filter cap and refill. See page 15 for quantity. Start engine and check for oil leaks at drain plug and filter housing. Diesel Engine Crankcase Breather

Remove breather tube cover and element. Wash with clean solvent or diesel fuel at each oil change period. Inspect seal and replace if necessary. Lubricating Grease

Use Multipurpose-type Grease which contains both 3 to 5% molybdenum disulfide conforming to MIL-M-7866, and a suitable corrosion inhibitor. NLGI No. 2 Grade is suitable for most temperatures. NLGI No. 1 or No. 0 are suitable for extremely low temperatures.Always clean fittings before lubricating.Fan Pulley Bearing

Lubricate every 10,000 miles. Lubricate through fitting until grease appears at relief fitting on front of fan hub. Wipe off excess grease. Water Pump Bearing

Lubricate every 10,000 miles. Lubricate through fitting until lubricant appears at relief fitting. Earlier engines have no relief fitting. Excess lubricant will appear at end of water pump shaft. Tachometer Drive

Lubricate every 10,000 miles. Remove plug. Install grease fitting and apply one stroke of lubricant through fitting.

The Lubrication and Maintenance Charts list the normal oil change periods as determined by fuel sulphur content. (Make an initial oil change after the first 500 miles of operation for reconditioned engines.)Use oils which meet Engine Service classification CD or MIL-L-2104C. These are additive-type oils that have been approved for use in Caterpillar Diesel Engines. Diesel Engine Crankcase

Check oil level daily before starting engine and when refueling. Check with the engine either running or stopped as indicated on the oil level gauge. Add oil when the level drops to the add oil mark. Drain the crankcase every 10,000 miles while engine is warm and stopped. If equipped with a 13 qt. supplemental filter system the normal interval can be extended to 15,000 miles. Install drain plug. Diesel Engine Crankcase Lubricating Oil Filter

Change filter element every 10,000 miles. Drain the filter housing by removing drain plug. Loosen bolt on the cover and remove the housing and filter element. Inspect seal and install a new one if necessary. Wash the inside of the filter housing and install a new Caterpillar filter element. After draining crankcase remove filter cap and refill. See page 15 for quantity. Start engine and check for oil leaks at drain plug and filter housing. Diesel Engine Crankcase Breather

Remove breather tube cover and element. Wash with clean solvent or diesel fuel at each oil change period. Inspect seal and replace if necessary. Lubricating Grease

Use Multipurpose-type Grease which contains both 3 to 5% molybdenum disulfide conforming to MIL-M-7866, and a suitable corrosion inhibitor. NLGI No. 2 Grade is suitable for most temperatures. NLGI No. 1 or No. 0 are suitable for extremely low temperatures.Always clean fittings before lubricating.Fan Pulley Bearing

Lubricate every 10,000 miles. Lubricate through fitting until grease appears at relief fitting on front of fan hub. Wipe off excess grease. Water Pump Bearing

Lubricate every 10,000 miles. Lubricate through fitting until lubricant appears at relief fitting. Earlier engines have no relief fitting. Excess lubricant will appear at end of water pump shaft. Tachometer Drive

Lubricate every 10,000 miles. Remove plug. Install grease fitting and apply one stroke of lubricant through fitting.

Have questions with 101681-9600?

Group cross 101681-9600 ZEXEL

Nissan-Diesel

101681-9600

9 400 610 785

16712Z5510

INJECTION-PUMP ASSEMBLY

FD6T07

FD6T07