Information injection-pump assembly

ZEXEL

101681-9570

1016819570

Rating:

Service parts 101681-9570 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

101681-9570

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

101681-9570

1016819570

Zexel num

Bosch num

Firm num

Name

101681-9570

INJECTION-PUMP ASSEMBLY

6105Q *

6105Q *

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.2

2.15

2.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

65

63

67

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

10

8.5

11.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

16+0.2

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

100

100

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1200

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

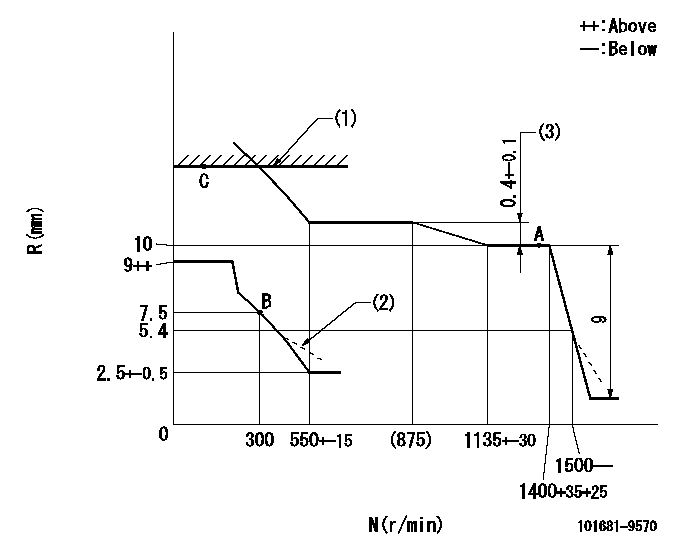

N:Pump speed

R:Rack position (mm)

(1)RACK LIMIT: RAL

(2)Damper spring setting: DL

(3)Rack difference between N = N1 and N = N2

----------

RAL=16+0.2mm DL=5.4-0.5mm N1=1400r/min N2=800r/min

----------

----------

RAL=16+0.2mm DL=5.4-0.5mm N1=1400r/min N2=800r/min

----------

0000000901

F:Full load

I:Idle

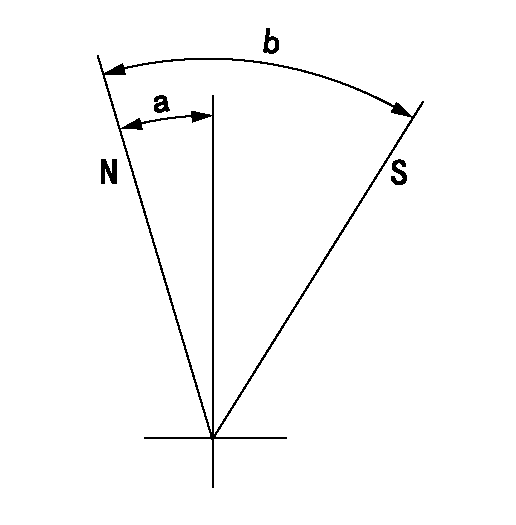

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=27deg+-3deg

----------

----------

a=10deg+-5deg b=27deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=25deg+-5deg b=71deg+-5deg

----------

----------

a=25deg+-5deg b=71deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of flange tooth's stamping at No. 1 cylinder's beginning of injection.

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

The 1674 Diesel Truck Engine is a 638 cu. in (10,5 ltr.) displacement, 4 stroke cycle, 6 cylinder turbocharged and aftercooled engine. This dual overhead cam engine with a 4 valve per cylinder design is made especially for highway trucks hauling big payloads. Serviceability is featured by spin-on throw away fuel filters, easy valve adjustment, replaceable cylinder liners and valve seats, and piston and rod removal from the top.Individual injection pumps, one for each cylinder, meter and pump fuel under high pressure to an injection valve and a precombustion chamber for each cylinder. An automatic variable timing device advances or retards fuel injection and is regulated by engine speed. The faster the engine turns the earlier the injection must take place before piston top center on the compression stroke.A hydro-mechanical governor controls the fuel injection pump out-put to maintain the engine RPM selected by the operator. A speed limiting device, in the governor, limits engine speed until engine oil pressure builds up.Inlet air, filtered by an air cleaner, is compressed by a turbocharger before entering the engine cylinders. The turbocharger is driven by the engine exhaust.There are four in-head valves (two inlet and two exhaust) for each cylinder. Two overhead camshafts, and forked rocker arm assemblies, are located in a housing on top of the cylinder head. The forked rocker arm assemblies act as a direct mechanical link between the lobes on the camshafts and the valve stems. The timing gears are located at the rear of the engine.Coolant for the engine is used to cool the engine lubricating oil. A full-flow temperature regulator, in the cylinder head at the front of the engine, provides for quick engine warm-up, and allows free circulation of coolant after operating temperature has been reached.Lubrication for the engine is supplied by a gear-type pump. The pump provides full pressure lubrication to the engine internal and external parts.The lubricating oil is both cooled and filtered. By-pass valves in the oil cooler assembly provide unrestricted flow of lubrication oil to the engine parts when oil viscosity is high or, if either the oil cooler or the oil filter element should become clogged.The starting system is direct electric and uses a 24 or 12 volt starting motor.Efficiency of emission controls and engine performance depends on adherence to proper operation and maintenance recommendations, and use of recommended fuels and lubrication oils. Major adjustments and repair should be entrusted to your authorized dealer. Follow the recommended maintenance schedule with special emphasis on fuel injection nozzles, air cleaner, fuel-air ratio control and high and low idle adjustment. Fuel-air ratio control and the high and low idle adjustments should be made by an authorized dealer.

Have questions with 101681-9570?

Group cross 101681-9570 ZEXEL

Nissan-Diesel

101681-9570

INJECTION-PUMP ASSEMBLY

6105Q

6105Q