Information injection-pump assembly

BOSCH

9 400 619 606

9400619606

ZEXEL

101681-9441

1016819441

Rating:

Service parts 101681-9441 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

101681-9441

as INJECTION-PUMP ASSEMBLY

Include in #2:

104745-3160

as _

Cross reference number

BOSCH

9 400 619 606

9400619606

ZEXEL

101681-9441

1016819441

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.2

2.15

2.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.9

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

55.5

54

57

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.7+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

9.4

8.1

10.7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60.5

60.5

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

550--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

700

Advance angle

deg.

1

0.5

1.5

Timer adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

2.7

2

3.4

Timer adjustment_05

Pump speed

r/min

1400

Advance angle

deg.

4.4

3.7

5.1

Timer adjustment_06

Pump speed

r/min

1500

Advance angle

deg.

4.8

4.1

5.5

Timer adjustment_07

Pump speed

r/min

-

Advance angle

deg.

6

6

6

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

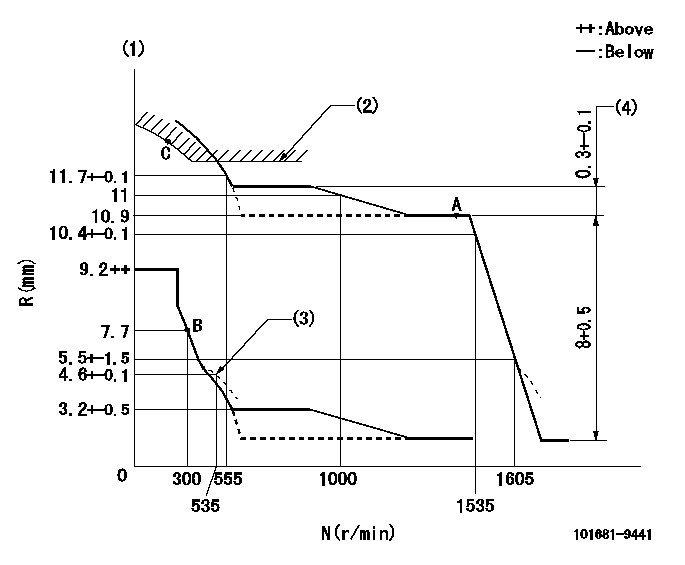

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Excess fuel lever setting: EXL (N = N1)

(3)Damper spring setting

(4)Rack difference between N = N2 and N = N3

----------

EXL=12.1+0.2mm N1=500r/min N2=1500r/min N3=900r/min

----------

----------

EXL=12.1+0.2mm N1=500r/min N2=1500r/min N3=900r/min

----------

0000000901

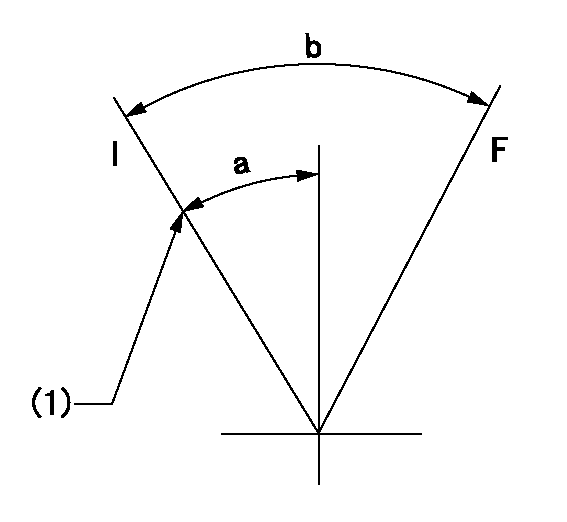

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=16deg+-5deg b=29.5deg+-3deg

----------

----------

a=16deg+-5deg b=29.5deg+-3deg

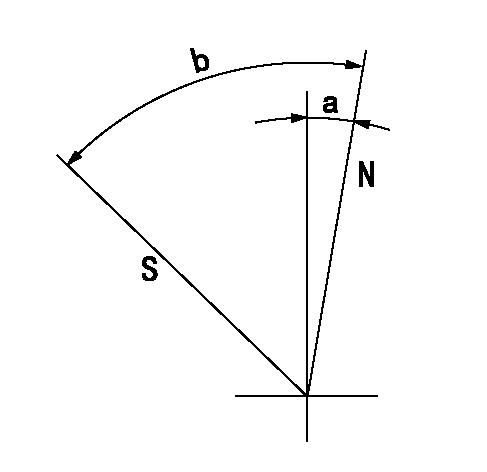

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=20deg+-5deg b=71deg+-5deg

----------

----------

a=20deg+-5deg b=71deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Introduction

Correction to D3G failures of the fuel injection pumpProblem

The D3G has had failures of the fuel injection pump. The failures are seen as low power, running rough, smoking, and hard starting. The failures occur from 8 to 1350 hours. Most failures have been concentrated in the 8 to 400 hour range. There appears to be no environmental aspects or application aspects to the failures at this time. Solution

The rotary fuel pump that is used on the Track-Type Tractors uses diesel fuel for lubrication of the pump. One plunger is used for all 6 injectors. This increases the sensitivity to fuel quality. Customers that are having problems should use 256-4968 Fuel Conditioner . This should help fuel quality by increasing the lubrication. This additive can also be used with low sulfur diesel. Use this fuel conditioner according to directions. For more information, refer to , PELJ0525, "Introducing New Cat Diesel Fuel Conditioner". Low sulfur diesel is already available in many states per the 2007 Highway Diesel Rule. Refer to the following map that shows the areas that produce lower sulfur diesel fuel.

Illustration 1 g01229705

Note: Toyu fuel is not suitable for use in these machines. Toyu fuel does not provide any lubrication for the pump. Using this fuel may cause early failures.

Correction to D3G failures of the fuel injection pumpProblem

The D3G has had failures of the fuel injection pump. The failures are seen as low power, running rough, smoking, and hard starting. The failures occur from 8 to 1350 hours. Most failures have been concentrated in the 8 to 400 hour range. There appears to be no environmental aspects or application aspects to the failures at this time. Solution

The rotary fuel pump that is used on the Track-Type Tractors uses diesel fuel for lubrication of the pump. One plunger is used for all 6 injectors. This increases the sensitivity to fuel quality. Customers that are having problems should use 256-4968 Fuel Conditioner . This should help fuel quality by increasing the lubrication. This additive can also be used with low sulfur diesel. Use this fuel conditioner according to directions. For more information, refer to , PELJ0525, "Introducing New Cat Diesel Fuel Conditioner". Low sulfur diesel is already available in many states per the 2007 Highway Diesel Rule. Refer to the following map that shows the areas that produce lower sulfur diesel fuel.

Illustration 1 g01229705

Note: Toyu fuel is not suitable for use in these machines. Toyu fuel does not provide any lubrication for the pump. Using this fuel may cause early failures.