Information injection-pump assembly

BOSCH

9 400 615 953

9400615953

ZEXEL

101672-0210

1016720210

Rating:

Service parts 101672-0210 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5-15300-097-0

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Include in #1:

101672-0210

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 615 953

9400615953

ZEXEL

101672-0210

1016720210

Zexel num

Bosch num

Firm num

Name

101672-0210

9 400 615 953

INJECTION-PUMP ASSEMBLY

D500 * 14BE PE6A PE

D500 * 14BE PE6A PE

101672-0210

9 400 615 953

1156007904 ISUZU

INJECTION-PUMP ASSEMBLY

D500 * 14BE PE6A PE

D500 * 14BE PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.2

2.15

2.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

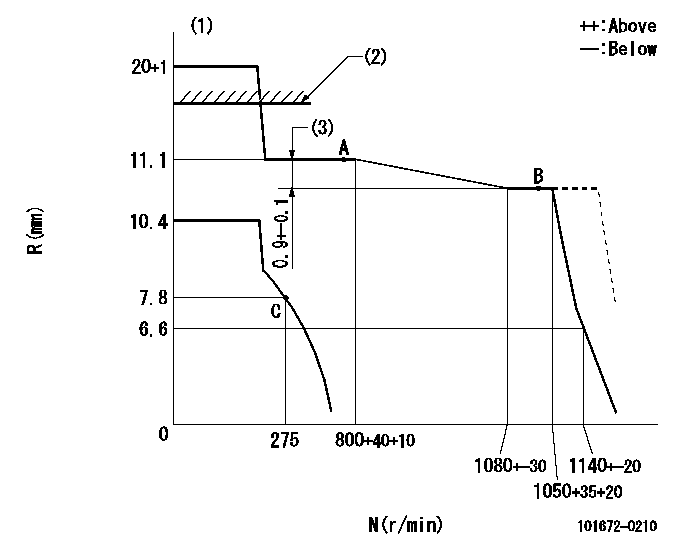

Injection quantity adjustment

Adjusting point

A

Rack position

11.1

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

45.2

43.7

46.7

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.2

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

43.5

41

46

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.3+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

9.4

7.9

10.9

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)Torque control stroke

----------

K=6 RAL=(17.5)mm

----------

----------

K=6 RAL=(17.5)mm

----------

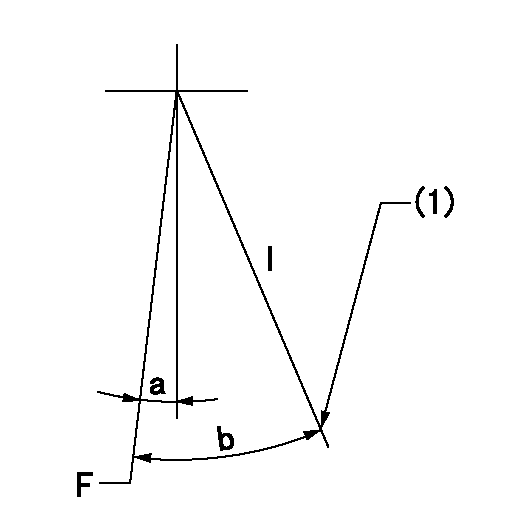

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=2deg+-5deg b=25.5deg+-5deg

----------

----------

a=2deg+-5deg b=25.5deg+-5deg

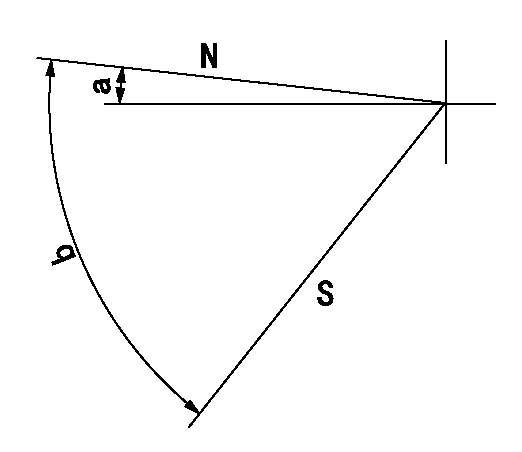

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=4.5deg+-5deg b=53deg+-5deg

----------

----------

a=4.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=15deg

----------

a=(100deg)

----------

aa=15deg

----------

a=(100deg)

Information:

TECHNICAL INFORMATION BULLETIN JAN. 15th, 2003

EXCAVATORS

WHEEL LOADERS

ENGINES 322C: (EMR, MAR);

325C: (CRB, CSJ, JLC, JLD, DTF)

950G II: (AYL, AYB);

962G II: (AYE, BAB)

3126B: (BMA)

Component Code(s) 1408SUBJECT: A NEW INJECTION ACTUATION PRESSURE CONTROL VALVE CONNECTOR INCREASES ENGINE OPERATION

PROBLEM:

The injection actuation pressure (IAP) control valve connector may have been assembled incorrectly on some 3126B engine harnesses. This can lead to intermittent engine operation or can cause the engine to stop.

SOLUTION:

If your machine exhibits symptoms of intermittent engine operation or abruptly stopping, the IAP control valve connector should be disconnected from the machine, examined for solenoid contact problems and re-installed using a correct procedure.

Procedure for installing the IAP control valve connector

This procedure will describe how to properly install the 232-4367 Harness.

Required Parts

Qty Part Number Description

1 232-4367 Harness

Procure the part that is listed in the table.

Illustration 1. Left Side of a 3126B Engine on a D6N.

(1) IAP Control Valve

(2) IAP Control Valve Connector

Note: Illustration 1 is from a D6N that is equipped with a 3126B for photographical purposes. The location of the IAP Control Valve is the same for your machine.

Disconnect the IAP control valve connector (2) from the IAP Control Valve (1). See Illustration 1.

Cut the two wires directly behind the connector.

Using wire strippers, strip the ends of the two wires.

Install the 232-4367 Harness, by crimping the stripped wires inside the splice.

Note: Take care to connect the pink wire to the pink wire on one hand and the purple wire to the purple wire on the other hand.

Heat both heat shrinkable tubes in order to insulate both the splices.

Reconnect the repaired harness to the IAP Control Valve (1).

COPYRIGHT 2003 CATERPILLAR

ALL RIGHTS RESERVED

Have questions with 101672-0210?

Group cross 101672-0210 ZEXEL

Isuzu

101672-0210

9 400 615 953

INJECTION-PUMP ASSEMBLY

D500

D500

Isuzu

101672-0210

9 400 615 953

1156007904

INJECTION-PUMP ASSEMBLY

D500

D500