Information injection-pump assembly

ZEXEL

101672-0170

1016720170

ISUZU

5156003806

5156003806

Rating:

Service parts 101672-0170 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5-15300-097-0

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Include in #1:

101672-0170

as INJECTION-PUMP ASSEMBLY

Include in #2:

104740-8580

as _

Cross reference number

ZEXEL

101672-0170

1016720170

ISUZU

5156003806

5156003806

Zexel num

Bosch num

Firm num

Name

101672-0170

5156003806 ISUZU

INJECTION-PUMP ASSEMBLY

D500 * K 14BE PE6A PE

D500 * K 14BE PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.2

2.15

2.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

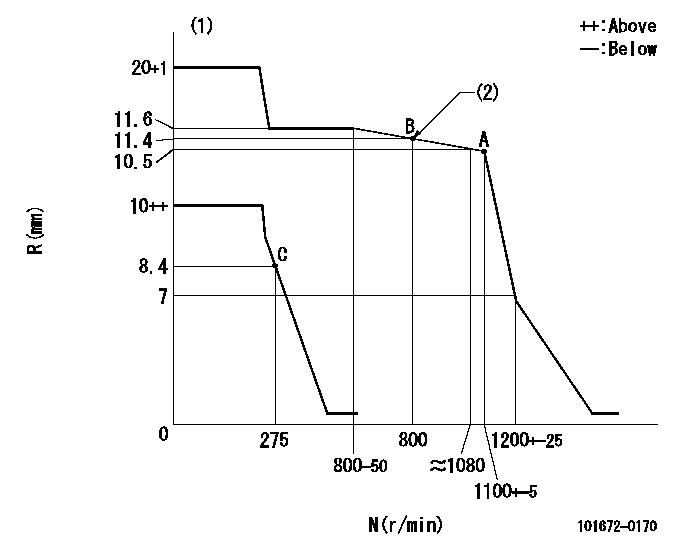

Injection quantity adjustment

Adjusting point

A

Rack position

10.5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44

43

45

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.4

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

47

44.8

49.2

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.4+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

8.6

7.1

10.1

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Set the torque control spring so that the injection quantity passes through point B.

----------

K=10

----------

----------

K=10

----------

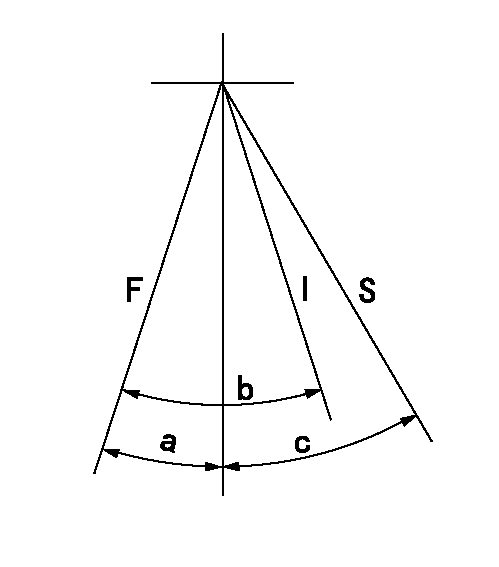

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=10deg+-5deg b=24deg+-5deg c=32deg+-3deg

----------

----------

a=10deg+-5deg b=24deg+-5deg c=32deg+-3deg

Information:

ACTION REQUIRED

After Failure:

1 - Update Engine Software, refer to UENR0611 Troubleshooting ? ECM Software ? Install, ensure to follow the steps to save the Engine Configuration data. Refer to the table in Image 1 to determine the correct engine software file to apply.

2 - Service CCB Filter and replace with new filter, refer to SEBU8727 Operation and Maintenance Manual ? Engine Crankcase Breather element ? Replace.

3 - Remove Diesel Particulate Filter, Refer to UENR0621 Disassembly and Assembly - Diesel Particulate Filter - Remove - Wall Flow Diesel Particulate Filter.

4 - Move the Diesel Particulate Filter Assembly to a suitable work surface.

5 - Refer to UENR0619 Specifications - Diesel Particulate Filter (Wall Flow Diesel Particulate Filter(DPF)), remove V Band Clamps (1)&(4), carefully split assembly and remove DPF Canister element.

6 - Using new DPF Kit Filter, reassemble the Diesel Particulate Filter Assembly noting the alignment marks previously made in Step 3, refer to UENR0619 Specifications - Diesel Particulate Filter (Wall Flow Diesel Particulate Filter(DPF)).

7 - Reinstall the Diesel Particulate Filter assembly, Refer to UENR0621 Disassembly and Assembly - Diesel Particulate Filter - Install - Wall Flow Diesel Particulate Filter.

8 - As the DPF has been replaced, ensure the ?DPF Replacement Reset? procedure is performed using CAT ET, refer to UENR0611 Troubleshooting - Service Tool Features - Components Replacement Resets.

Image1

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 1*******

0-3000 hrs,

0-60 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 6.0-hour job for Group 1

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 2*******

0-3000 hrs,

0-60 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 6.0-hour job for Group 2

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 101672-0170?

Group cross 101672-0170 ZEXEL

Isuzu

101672-0170

5156003806

INJECTION-PUMP ASSEMBLY

D500

D500