Information injection-pump assembly

BOSCH

9 400 615 951

9400615951

ZEXEL

101671-9740

1016719740

NISSAN-DIESEL

1671395012

1671395012

Rating:

Service parts 101671-9740 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-95000

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}

15.

NOZZLE SET

Include in #1:

101671-9740

as INJECTION-PUMP ASSEMBLY

Include in #2:

104740-8500

as _

Cross reference number

BOSCH

9 400 615 951

9400615951

ZEXEL

101671-9740

1016719740

NISSAN-DIESEL

1671395012

1671395012

Zexel num

Bosch num

Firm num

Name

101671-9740

9 400 615 951

1671395012 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

ND604 * K 14BE PE6A PE

ND604 * K 14BE PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.5

2.45

2.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

12.7

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

69.2

67.7

70.7

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

12.7

Pump speed

r/min

1350

1350

1350

Average injection quantity

mm3/st.

76.5

74.5

78.5

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

9

7.8

10.2

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Timer adjustment

Pump speed

r/min

300

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

600

Advance angle

deg.

1.3

0.8

1.8

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

3.5

3

4

Timer adjustment_04

Pump speed

r/min

1400

Advance angle

deg.

6

5.5

6.5

Remarks

Finish

Finish

Test data Ex:

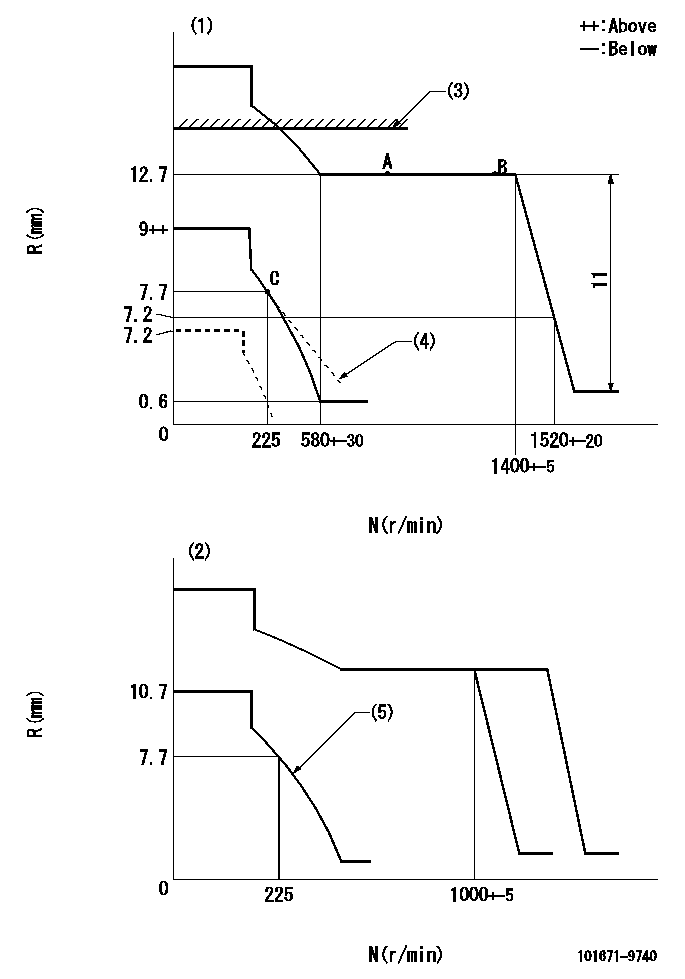

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Adjust with speed control lever at full position (minimum-maximum speed specification)

(2)Adjust with the load control lever in the full position (variable speed specification).

(3)RACK LIMIT: RAL

(4)Damper spring setting: DL

(5)Set idle sub-spring

----------

RAL=13+-0.1mm DL=7.7-0.2mm

----------

----------

RAL=13+-0.1mm DL=7.7-0.2mm

----------

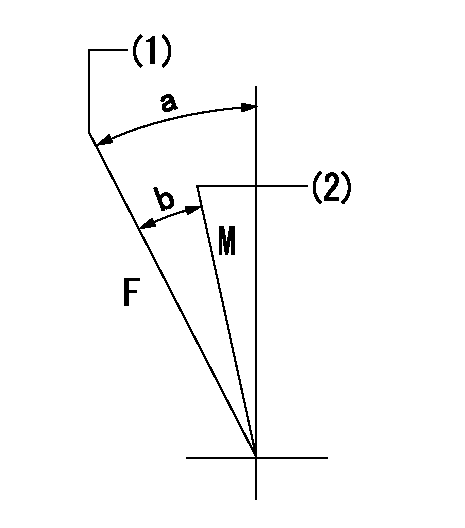

Speed control lever angle

F:Full speed

M:Minimum-maximum speed

(1)Pump speed = aa

(2)Pump speed = bb

----------

aa=1400r/min bb=1000r/min

----------

a=20deg+-5deg b=11deg+-5deg

----------

aa=1400r/min bb=1000r/min

----------

a=20deg+-5deg b=11deg+-5deg

0000000901

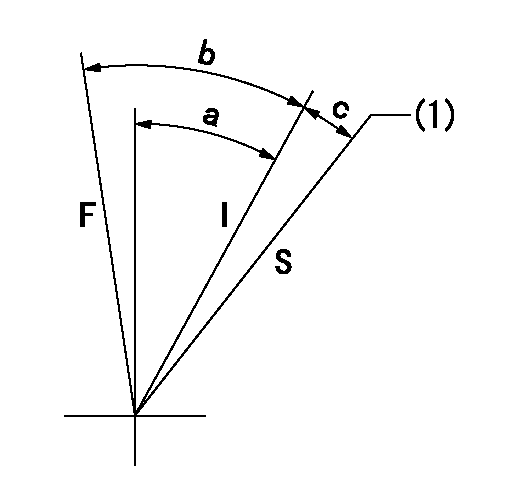

F:Full load

I:Idle

S:Stop

(1)Rack position aa (pump speed bb r/min )

----------

aa=7.2mm bb=0r/min

----------

a=26deg+-5deg b=36deg+-3deg c=12deg+-3deg

----------

aa=7.2mm bb=0r/min

----------

a=26deg+-5deg b=36deg+-3deg c=12deg+-3deg

Information:

ACTION REQUIRED

Refer to the attached Rework Procedure.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-2000 hrs,

0-24 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 2.0-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Rework Procedure

Use the procedures on the following pages in order to apply the updates to your machine.

- Park the machine on a firm, level surface.

- Fully retract and lower the boom.

- Place the travel select lever in the (N) NEUTRAL position.

- Apply Park Brake.

- Shut the engine off and remove the key from the MAIN switch located inside the engine compartment.

- Properly disconnect the battery.

- Place a Do Not Operate Tag on both the ignition key-switch and the steering wheel, stating that the machine should not be operated.

- Allow the engine area and antifreeze to cool down.

- Remove the cab rear cover.

- Use all applicable safety precautions while working on, around or under any machinery.

1. Locate DEF coolant supply hose (1) and DEF coolant return hose (2) on the engine. Refer to Image1.2.1.

Image1.2.1

2. Trace the routing of DEF coolant supply hose (1) on the engine to DEF coolant control valve (3) located in the middle of the frame. Refer to Image1.2.1 and 1.3.1.

Image1.3.1

3. Trace the routing of DEF coolant return hose (2) from the engine to DEF tank (4) located behind rear of the cab. Refer to Image1.2.1 and 1.4.1.

Image1.4.1

4. If the routing of DEF coolant supply hose (1) and DEF coolant return hose (2) are found to be correct, remount the cab rear cover and place the unit back in service.

5. If the routing of DEF coolant line (1) and DEF coolant return hose (2) are found to be incorrect, please continue the next steps to correct the DEF coolant line installation.

6. Remove all the cable straps that securing the two DEF coolant lines together or to other hoses. Refer to Image1.6.1. Some of the parts have been removed for clarity. Cut the 610cm of 5P-0767 Hose into two pieces: 330cm and 280cm.

Image1.6.1

7. Taking all precautions to minimize and contain any antifreeze spillage, disconnect DEF coolant supply hose (1) from DEF coolant control valve (3) and from the engine side DEF coolant supply port. The hose will not be reused. Retain the hose clamps for reuse. Refer to Image1.2.1 and 1.4.1.

8. Disconnect DEF coolant return hose (2) from DEF coolant tank (4) and from the engine side DEF coolant return port. The hose will not be reused. Retain the hose clamps for reuse. Refer to Image1.2.1 and 1.6.1.

9. Identify the new DEF coolant supply hose. It is the shorter

Have questions with 101671-9740?

Group cross 101671-9740 ZEXEL

Nissan-Diesel

101671-9740

9 400 615 951

1671395012

INJECTION-PUMP ASSEMBLY

ND604

ND604