Information injection-pump assembly

ZEXEL

101670-9040

1016709040

BOSCH

0400866093

0400866093

Rating:

Include in #2:

104740-8250

as _

Cross reference number

ZEXEL

101670-9040

1016709040

BOSCH

0400866093

0400866093

Zexel num

Bosch num

Firm num

Name

101670-9040

0400866093 BOSCH

INJECTION-PUMP ASSEMBLY

F6L912 K 14BE INJECTION PUMP ASSY PE6A PE

F6L912 K 14BE INJECTION PUMP ASSY PE6A PE

101670-9040

9 400 615 945

INJECTION-PUMP ASSEMBLY

F6L912 K 14BE INJECTION PUMP ASSY PE6A PE

F6L912 K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

98

98

98

Tester oil delivery pressure

kgf/cm2

1

1

1

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

1.9

1.9

2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.6

Pump speed

r/min

1130

1130

1130

Each cylinder's injection qty

mm3/st.

63.8

62.8

64.8

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.5+-0.5

Pump speed

r/min

325

325

325

Each cylinder's injection qty

mm3/st.

10.5

9.5

11.5

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

-

Pump speed

r/min

1130

1130

1130

Average injection quantity

mm3/st.

63.8

63.3

64.3

Fixing the lever

*

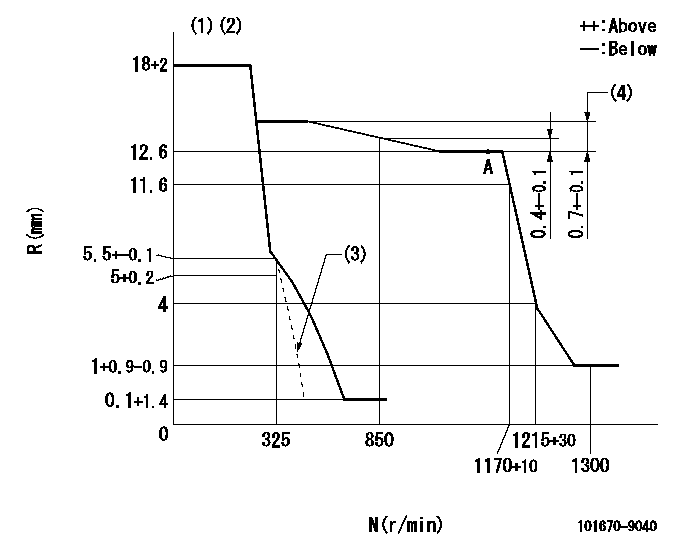

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Torque control stroke: L1 (N = N1 and N = N2 rack difference).

(3)Main spring setting

(4)Torque control stroke

----------

K=(12) L1=0.7+-0.05mm N1=1130r/min N2=500r/min

----------

----------

K=(12) L1=0.7+-0.05mm N1=1130r/min N2=500r/min

----------

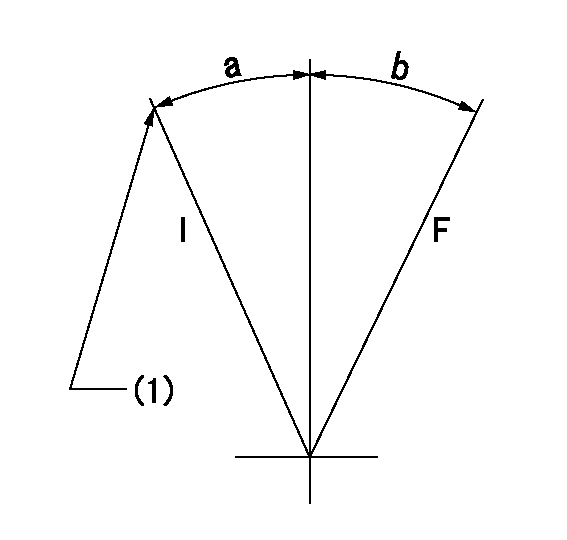

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=22deg+-4deg b=12deg+-4deg

----------

----------

a=22deg+-4deg b=12deg+-4deg

Information:

Start By:a. disassemble governorb. remove fuel injection pumps 1. Remove cover (1) from the fuel injection pump housing. 2. Remove rack (2) from the fuel injection pump housing.

If the original lifters are to be installed in the fuel injection pump housing, put identification marks on them as to their location in the housing.

3. Remove lifters (3) from the fuel injection pump housing. 4. Put the fuel injection pump housing on end on blocks, and use Tool (A) to remove snap ring (4) from the camshaft. 5. Use a soft hammer to push the camshaft toward the governor end of the fuel injection pump housing to loosen washer (5) on the camshaft. Remove washer (5). 6. Remove camshaft (6) from the fuel injection pump housing. 7. Remove bearings (7) from the drive end of the fuel injection pump housing. 8. Remove bearings (8) from the governor end of the fuel injection pump housing.Assemble Fuel Injection Pump Housing

Be sure all oil passages are clear and put clean engine oil on all parts before assembly.1. Use Tool (A) to install bearing (2) in the governor end of the fuel injection pump housing with joint (3) toward the top of the fuel injection pump housing. Install the bearing so it is 0.25 0.20 mm (.010 0.008 in) below the surface of the housing.2. Use Tool (A) to install bearing (1) in the governor end of the fuel injection pump housing so it is 7.16 0.13 mm (0.282 0.005 in) below the surface of the housing. 3. Use Tool (A) to install bearing (4) in the drive end of the fuel injection pump housing with the joint in the bearing toward the top of the fuel injection pump housing. Install the bearing so it is 1.00 0.25 mm (0.039 0.010 in) below the surface of the housing. 4. Install plate assembly (6) of Tool (C) on the drive end of the fuel injection pump housing to install the bearing for the rack. Use clean grease to hold the new rack bearing on driver (5) of Tool (C). Install the driver and bearing in plate assembly (6) with the groove in the driver in alignment with the pin in the plate. Use a hammer to push the bearing into position. The bearing will be installed to the correct depth when the shoulder of the driver is against plate assembly (6).5. Remove Tool (C) from the fuel injection pump housing. The rack bearing must be installed so it is 0.25 0.25 mm (0.010 0.010 in) below the surface of the housing. 6. Install camshaft (7) in the fuel injection pump housing.7. Put the fuel injection pump housing on end, and put a block under the camshaft. 8. Put washer (9) over the end of the camshaft, and use Tool (A) and a spacer (8) that has an inside diameter of 38.1 mm (1.5 in) and a length of 31.75 mm (1.25 in) to push the washer

If the original lifters are to be installed in the fuel injection pump housing, put identification marks on them as to their location in the housing.

3. Remove lifters (3) from the fuel injection pump housing. 4. Put the fuel injection pump housing on end on blocks, and use Tool (A) to remove snap ring (4) from the camshaft. 5. Use a soft hammer to push the camshaft toward the governor end of the fuel injection pump housing to loosen washer (5) on the camshaft. Remove washer (5). 6. Remove camshaft (6) from the fuel injection pump housing. 7. Remove bearings (7) from the drive end of the fuel injection pump housing. 8. Remove bearings (8) from the governor end of the fuel injection pump housing.Assemble Fuel Injection Pump Housing

Be sure all oil passages are clear and put clean engine oil on all parts before assembly.1. Use Tool (A) to install bearing (2) in the governor end of the fuel injection pump housing with joint (3) toward the top of the fuel injection pump housing. Install the bearing so it is 0.25 0.20 mm (.010 0.008 in) below the surface of the housing.2. Use Tool (A) to install bearing (1) in the governor end of the fuel injection pump housing so it is 7.16 0.13 mm (0.282 0.005 in) below the surface of the housing. 3. Use Tool (A) to install bearing (4) in the drive end of the fuel injection pump housing with the joint in the bearing toward the top of the fuel injection pump housing. Install the bearing so it is 1.00 0.25 mm (0.039 0.010 in) below the surface of the housing. 4. Install plate assembly (6) of Tool (C) on the drive end of the fuel injection pump housing to install the bearing for the rack. Use clean grease to hold the new rack bearing on driver (5) of Tool (C). Install the driver and bearing in plate assembly (6) with the groove in the driver in alignment with the pin in the plate. Use a hammer to push the bearing into position. The bearing will be installed to the correct depth when the shoulder of the driver is against plate assembly (6).5. Remove Tool (C) from the fuel injection pump housing. The rack bearing must be installed so it is 0.25 0.25 mm (0.010 0.010 in) below the surface of the housing. 6. Install camshaft (7) in the fuel injection pump housing.7. Put the fuel injection pump housing on end, and put a block under the camshaft. 8. Put washer (9) over the end of the camshaft, and use Tool (A) and a spacer (8) that has an inside diameter of 38.1 mm (1.5 in) and a length of 31.75 mm (1.25 in) to push the washer

Have questions with 101670-9040?

Group cross 101670-9040 ZEXEL

Nissan-Diesel

Bosch

Bosch

101670-9040

0400866093

INJECTION-PUMP ASSEMBLY

F6L912

F6L912

101670-9040

9 400 615 945

INJECTION-PUMP ASSEMBLY

F6L912

F6L912