Information injection-pump assembly

ZEXEL

101641-9020

1016419020

NISSAN-DIESEL

1670090916

1670090916

Rating:

Service parts 101641-9020 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-90019

12.

Open Pre:MPa(Kqf/cm2)

9.8{100}

15.

NOZZLE SET

Include in #1:

101641-9020

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

101641-9020

1016419020

NISSAN-DIESEL

1670090916

1670090916

Zexel num

Bosch num

Firm num

Name

101641-9020

1670090916 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

SD33T * K

SD33T * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.3

2.25

2.35

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

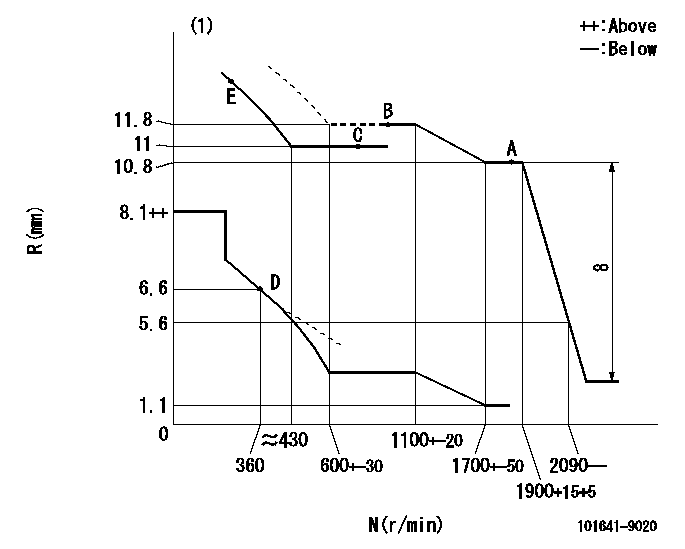

Injection quantity adjustment

Adjusting point

A

Rack position

10.8

Pump speed

r/min

1900

1900

1900

Average injection quantity

mm3/st.

43.4

42.4

44.4

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.8

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

45.4

43.4

47.4

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Injection quantity adjustment_03

Adjusting point

C

Rack position

11

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

37.6

35.6

39.6

Max. variation between cylinders

%

0

-5

5

Fixing the rack

*

Boost pressure

kPa

25.3

Boost pressure

mmHg

190

Injection quantity adjustment_04

Adjusting point

D

Rack position

7.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

7.5

6.4

8.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_05

Adjusting point

E

Rack position

12.8++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

40

40

50

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

1100

1100

1100

Rack position

11

Boost pressure

kPa

26.7

25.4

28

Boost pressure

mmHg

200

190

210

Boost compensator adjustment_02

Pump speed

r/min

1100

1100

1100

Rack position

11.8

Boost pressure

kPa

46.7

40

53.4

Boost pressure

mmHg

350

300

400

Timer adjustment

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

1

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

2.2

1.7

2.7

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

4.7

4.2

5.2

Timer adjustment_05

Pump speed

r/min

1900

Advance angle

deg.

7.5

7

8

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

----------

DL=5.8-0.5mm

----------

----------

DL=5.8-0.5mm

----------

0000000901

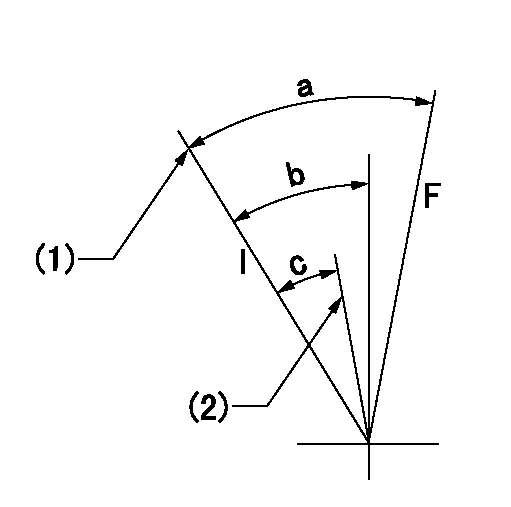

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Microswitch OFF position

----------

----------

a=35deg+-3deg b=30deg+-5deg c=(25.5deg)

----------

----------

a=35deg+-3deg b=30deg+-5deg c=(25.5deg)

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=35deg+-5deg b=41.5deg+-5deg

----------

----------

a=35deg+-5deg b=41.5deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is OFF.

(1)Speed N1

(2)Rack position Ra

----------

N1=1200r/min Ra=8.7mm

----------

----------

N1=1200r/min Ra=8.7mm

----------

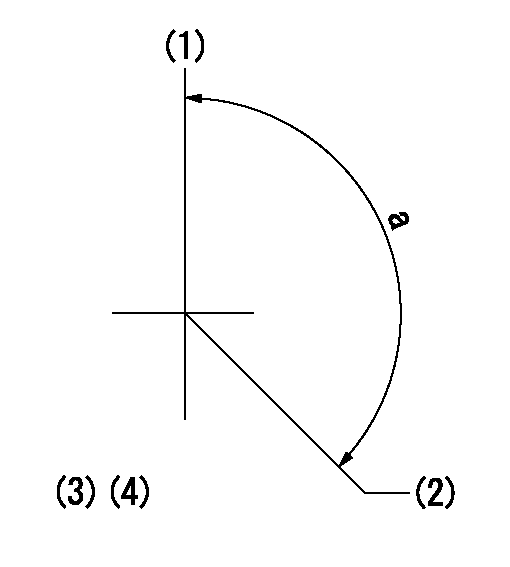

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'Y' at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(130deg)

----------

----------

a=(130deg)

Information:

Caterpillar Reference Material

The following literature can be obtained through any Caterpillar dealer.Oil

SEBD0640, Oil and Your EnginePEDP7122, Question & Answer BookletPEDP1129, Listen To Your OilPEHP6001, How to Take a Good Oil SampleSEBU6251, Lubricant RecommendationsPEHP5026, Product Data Sheet for Cat Diesel Engine Oil (DEO) (CG4/CF-4) (North America & Selected International)PEHP1026, Product Data Sheet for Cat Diesel Engine Oil (CF-4)(International Only)PEHP1027, Product Data Sheet for Cat Diesel Engine Oil (CD)PEHP0002, Product Data Sheet for Cat Molybdenum Grease (MPGM)PEHP0003, Product Data Sheet for Cat Lithium Grease (MPGL)PEHP0017, Product Data Sheet for Cat Special Purpose Grease (SPG)PEWP9733, Cat Fluids SelectorPEDP7105, Scheduled Oil SamplingPECP4025, One Safe SourceFuel

SEBD0717, Diesel Fuels and Your EngineCoolant

SEBD0518, Know Your Cooling SystemSEBD0970, Coolant and Your EnginePEHP4036, Data Sheet-Caterpillar CoolantPEHP5033, S O S Coolant AnalysisPECP4025, One Safe SourceMiscellaneous

SEBF8029, Index to Guidelines for Reusable Parts and Salvage OperationsSEBF8062, Guideline for Reusable Parts - Cleaning and Inspection of Air FiltersSEHS9031, Storage Procedure for Caterpillar ProductsSENR5226, Service Manual (EMCP)SEBU6150, SR4 Generators and Control Panels Operation and Maintenance ManualSENR2380, Service Manual (4XB, 7JB, 64Z, 83Z & 10E300-up)SENR2793, Service Manual (85Z, 2AJ & 2TM)SEBP1805, Parts Manual (2AJ)SEBP2273, Parts Manual (2TM)SEBP1451, Parts Manual (7JB)SEBP1452, Parts Manual (4XB)SEBP1406, Parts Manual (85Z)SEBP1411, Parts Manual (83Z)SEBP1435, Parts Manual (64Z)SEBP1400, Parts Manual (10E300-up)SEHS7654, Alignment-General InstructionsSEHS9124, Cleaning and Drying of Caterpillar Electric Set GeneratorsLEBH9324, Agricultural and Material Handling Application and Installation GuideSEHS7292, Use of 5P4150 Nozzle Testing GroupSEHS8622, Using the FT1984 Air-To-Air Aftercooler Leak Test GroupSEHS7795, Use of Pump & Governor Tool GroupSEHS8024, Governor Adjusting Tool GroupSEHS8094, Use of Nozzle Puller GroupAdditional Reference Material

Society of Automotive Engineers (SAE) Specs can be found in your SAE handbook or can be obtained from your local library, college or technological society.* SAE handbooks can be obtained directly from:SAE International

400 Commonwealth Drive

Warrendale, PA USA 15096-0001

Engine Manufacturers Association (EMA) information for lube oil selection can be obtained from your local library, college or technological society, or contact:Engine Manufacturers Association

Lubricating Oils Data Book

401 N. Michigan Ave. Ste. 2400

Chicago, IL 60611

(312) 644-6610 ext. 3626

American Society for Testing and Materials (ASTM) specifications can normally be obtained from your local technological siciety, library or college, or contact:American Society for Testing and Materials

1916 Race Street

Philadelphia, PA 19103

Emissions Warranty

The engine described in this manual may be certified and covered by an Emissions Warranty. A detailed explanation of the Emissions Warranty, applicable to certified engines, is found in SEBU6981, Emissions Control Warranty Information. The engine is certified if it has a special certification label. A Caterpillar dealer can also inform you if the engine is certified.

The following literature can be obtained through any Caterpillar dealer.Oil

SEBD0640, Oil and Your EnginePEDP7122, Question & Answer BookletPEDP1129, Listen To Your OilPEHP6001, How to Take a Good Oil SampleSEBU6251, Lubricant RecommendationsPEHP5026, Product Data Sheet for Cat Diesel Engine Oil (DEO) (CG4/CF-4) (North America & Selected International)PEHP1026, Product Data Sheet for Cat Diesel Engine Oil (CF-4)(International Only)PEHP1027, Product Data Sheet for Cat Diesel Engine Oil (CD)PEHP0002, Product Data Sheet for Cat Molybdenum Grease (MPGM)PEHP0003, Product Data Sheet for Cat Lithium Grease (MPGL)PEHP0017, Product Data Sheet for Cat Special Purpose Grease (SPG)PEWP9733, Cat Fluids SelectorPEDP7105, Scheduled Oil SamplingPECP4025, One Safe SourceFuel

SEBD0717, Diesel Fuels and Your EngineCoolant

SEBD0518, Know Your Cooling SystemSEBD0970, Coolant and Your EnginePEHP4036, Data Sheet-Caterpillar CoolantPEHP5033, S O S Coolant AnalysisPECP4025, One Safe SourceMiscellaneous

SEBF8029, Index to Guidelines for Reusable Parts and Salvage OperationsSEBF8062, Guideline for Reusable Parts - Cleaning and Inspection of Air FiltersSEHS9031, Storage Procedure for Caterpillar ProductsSENR5226, Service Manual (EMCP)SEBU6150, SR4 Generators and Control Panels Operation and Maintenance ManualSENR2380, Service Manual (4XB, 7JB, 64Z, 83Z & 10E300-up)SENR2793, Service Manual (85Z, 2AJ & 2TM)SEBP1805, Parts Manual (2AJ)SEBP2273, Parts Manual (2TM)SEBP1451, Parts Manual (7JB)SEBP1452, Parts Manual (4XB)SEBP1406, Parts Manual (85Z)SEBP1411, Parts Manual (83Z)SEBP1435, Parts Manual (64Z)SEBP1400, Parts Manual (10E300-up)SEHS7654, Alignment-General InstructionsSEHS9124, Cleaning and Drying of Caterpillar Electric Set GeneratorsLEBH9324, Agricultural and Material Handling Application and Installation GuideSEHS7292, Use of 5P4150 Nozzle Testing GroupSEHS8622, Using the FT1984 Air-To-Air Aftercooler Leak Test GroupSEHS7795, Use of Pump & Governor Tool GroupSEHS8024, Governor Adjusting Tool GroupSEHS8094, Use of Nozzle Puller GroupAdditional Reference Material

Society of Automotive Engineers (SAE) Specs can be found in your SAE handbook or can be obtained from your local library, college or technological society.* SAE handbooks can be obtained directly from:SAE International

400 Commonwealth Drive

Warrendale, PA USA 15096-0001

Engine Manufacturers Association (EMA) information for lube oil selection can be obtained from your local library, college or technological society, or contact:Engine Manufacturers Association

Lubricating Oils Data Book

401 N. Michigan Ave. Ste. 2400

Chicago, IL 60611

(312) 644-6610 ext. 3626

American Society for Testing and Materials (ASTM) specifications can normally be obtained from your local technological siciety, library or college, or contact:American Society for Testing and Materials

1916 Race Street

Philadelphia, PA 19103

Emissions Warranty

The engine described in this manual may be certified and covered by an Emissions Warranty. A detailed explanation of the Emissions Warranty, applicable to certified engines, is found in SEBU6981, Emissions Control Warranty Information. The engine is certified if it has a special certification label. A Caterpillar dealer can also inform you if the engine is certified.

Have questions with 101641-9020?

Group cross 101641-9020 ZEXEL

Nissan-Diesel

101641-9020

1670090916

INJECTION-PUMP ASSEMBLY

SD33T

SD33T