Information injection-pump assembly

BOSCH

9 400 610 278

9400610278

ZEXEL

101631-9753

1016319753

NISSAN-DIESEL

16700C8603

16700c8603

Rating:

Service parts 101631-9753 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-36W00

12.

Open Pre:MPa(Kqf/cm2)

9.8{100}

15.

NOZZLE SET

Include in #1:

101631-9753

as INJECTION-PUMP ASSEMBLY

Include in #2:

104740-3260

as _

Cross reference number

BOSCH

9 400 610 278

9400610278

ZEXEL

101631-9753

1016319753

NISSAN-DIESEL

16700C8603

16700c8603

Zexel num

Bosch num

Firm num

Name

101631-9753

9 400 610 278

16700C8603 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

SD33 * K 14BE PE6A PE

SD33 * K 14BE PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.15

2.1

2.2

Rack position

R=11.6

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.6

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

33.1

32.1

34.1

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.1+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

7.5

6.4

8.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

550--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

2.2

1.7

2.7

Timer adjustment_04

Pump speed

r/min

1900

Advance angle

deg.

7.5

7

8

Remarks

Finish

Finish

Test data Ex:

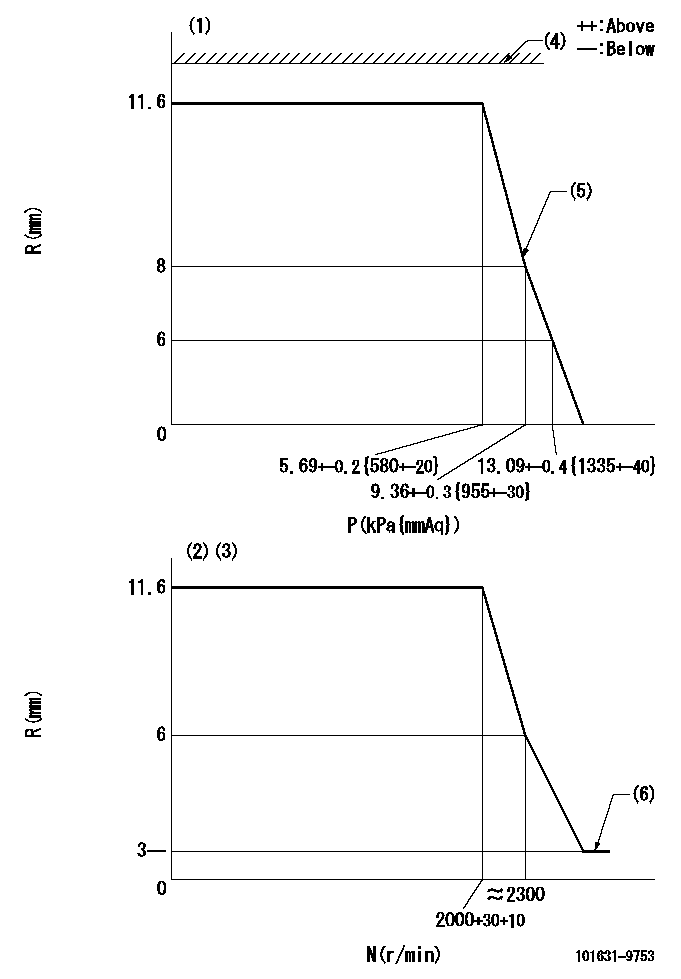

Governor adjustment

N:Pump speed

R:Rack position (mm)

P:Negative pressure

(1)Pneumatic governor

(2)Mechanical governor

(3)Acting negative pressure: P1

(4)RACK LIMIT: RAL

(5)Beginning of idle sub spring operation: L1

(6)Injection quantity Q = Q1 or less

----------

P1=3.63+-0.2kPa(370+-20mmAq) RAL=16-0.3mm L1=8+0.3mm Q1=3mm3/st

----------

----------

P1=3.63+-0.2kPa(370+-20mmAq) RAL=16-0.3mm L1=8+0.3mm Q1=3mm3/st

----------

0000001101

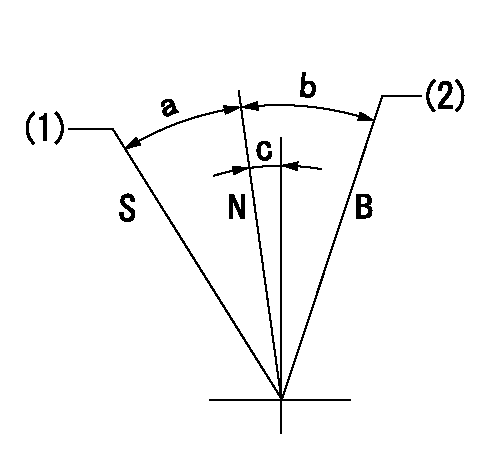

N:Normal

B:When boosted

S:Stop

(1)Rack position = aa

(2)Rack position bb

----------

aa=0mm bb=16mm

----------

a=23.5deg+-3deg b=8.5deg+-5deg c=2deg+-5deg

----------

aa=0mm bb=16mm

----------

a=23.5deg+-3deg b=8.5deg+-5deg c=2deg+-5deg

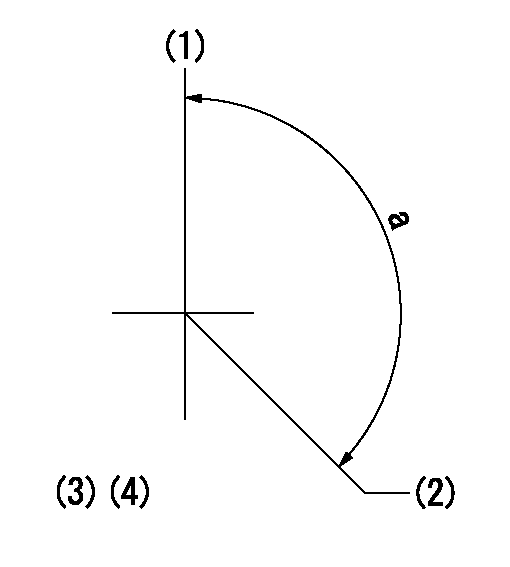

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'Y' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=20deg

----------

a=(130deg)

----------

aa=20deg

----------

a=(130deg)

Information:

Start By:a. remove rocker shaft and push rods Valve guide seals for the inlet valves and O-ring seals for the exhaust valves can be removed without removal of the cylinder head by use of the method shown. Pressure air is used to hold the valves in position while the valve springs and retainers are removed. Use an old fuel injection nozzle to make an air chuck adapter. 1. Remove the fuel injection nozzle assembly, and put the piston on TDC (top dead center) for the respective cylinder for which the valve stem seal and O-ring seals are to be removed.2. Install air chuck adapter (2). Fasten a pressure air source to pressurize the cylinder.3. Use tooling (A) to compress the valve springs. Use magnet bar (1) to hold the keepers.4. Remove tool (A), and remove the valve springs and retainer. 5. Remove exhaust valve O-ring seal (3) and inlet valve guide seal (4).

Do not release air pressure in the cylinder until the valve springs and retainer have been installed. Failure to do so will let the valve fall into the top of the piston. If the piston is not at TDC (top dead center) the valve can fall into the cylinder making cylinder head removal necessary.

Install Valve Guide Seals

1. Install spring seating washer (1). 2. Put clean engine oil on the part of valve guide seal (2) that makes contact with the valve stem. Install valve guide seal (2).

The closed coil of the spring must be toward the cylinder rod.

3. Put inner and outer springs (4) and retainer (3) in position.

The locks can be thrown from the valve when the compressor is released if they are not in their correct position on the valve stem.

4. Use tool (A) to compress the valve springs so the keepers can be installed.5. Use tool (B) to install the keepers.6. Repeat Steps 1-4 for O-ring seals (5) on the exhaust valve.7. Move the piston off T.D.C. (top dead center) and tap the valve spring retainer with a soft hammer to be sure the retainers are properly seated.8. Install the fuel injection nozzle assembly.End By:a. install rocker shaft and push rods

Do not release air pressure in the cylinder until the valve springs and retainer have been installed. Failure to do so will let the valve fall into the top of the piston. If the piston is not at TDC (top dead center) the valve can fall into the cylinder making cylinder head removal necessary.

Install Valve Guide Seals

1. Install spring seating washer (1). 2. Put clean engine oil on the part of valve guide seal (2) that makes contact with the valve stem. Install valve guide seal (2).

The closed coil of the spring must be toward the cylinder rod.

3. Put inner and outer springs (4) and retainer (3) in position.

The locks can be thrown from the valve when the compressor is released if they are not in their correct position on the valve stem.

4. Use tool (A) to compress the valve springs so the keepers can be installed.5. Use tool (B) to install the keepers.6. Repeat Steps 1-4 for O-ring seals (5) on the exhaust valve.7. Move the piston off T.D.C. (top dead center) and tap the valve spring retainer with a soft hammer to be sure the retainers are properly seated.8. Install the fuel injection nozzle assembly.End By:a. install rocker shaft and push rods

Have questions with 101631-9753?

Group cross 101631-9753 ZEXEL

Nissan-Diesel

Nissan-Diesel

101631-9753

9 400 610 278

16700C8603

INJECTION-PUMP ASSEMBLY

SD33

SD33