Information injection-pump assembly

ZEXEL

101631-9600

1016319600

NISSAN-DIESEL

16700C6809

16700c6809

Rating:

Service parts 101631-9600 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-20053

12.

Open Pre:MPa(Kqf/cm2)

9.8{100}

15.

NOZZLE SET

Include in #1:

101631-9600

as INJECTION-PUMP ASSEMBLY

Include in #2:

104740-3070

as _

Cross reference number

ZEXEL

101631-9600

1016319600

NISSAN-DIESEL

16700C6809

16700c6809

Zexel num

Bosch num

Firm num

Name

101631-9600

16700C6809 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

SD33 * K

SD33 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.15

2.1

2.2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.2

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

32.5

31.5

33.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.7

Pump speed

r/min

1900

1900

1900

Average injection quantity

mm3/st.

36.6

35

38.2

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

7.5

6.5

8.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

550

Advance angle

deg.

0.7

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

1.7

1.2

2.2

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

3.6

3.1

4.1

Timer adjustment_05

Pump speed

r/min

1900

Advance angle

deg.

6

5.5

6.5

Remarks

Finish

Finish

Test data Ex:

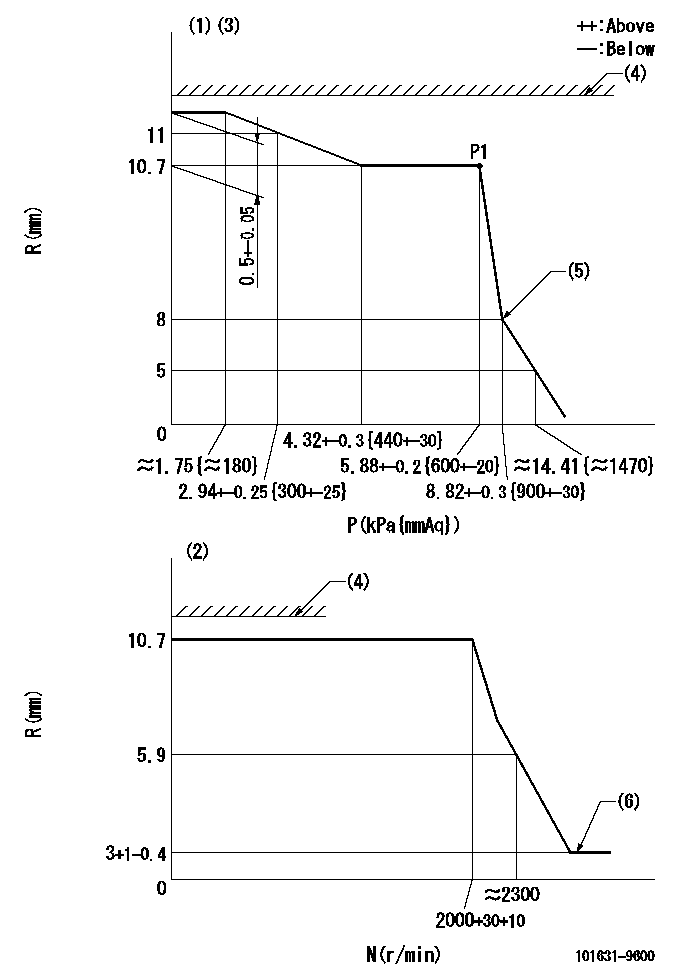

Governor adjustment

N:Pump speed

R:Rack position (mm)

P:Negative pressure

(1)Pneumatic governor

(2)Mechanical governor

(3)Acting negative pressure: P1

(4)RACK LIMIT: RAL

(5)Beginning of idle sub spring operation: L1

(6)Injection quantity Q = Q1 or less

----------

RAL=11.7-0.3mm L1=8+0.3mm Q1=3mm3/st

----------

----------

RAL=11.7-0.3mm L1=8+0.3mm Q1=3mm3/st

----------

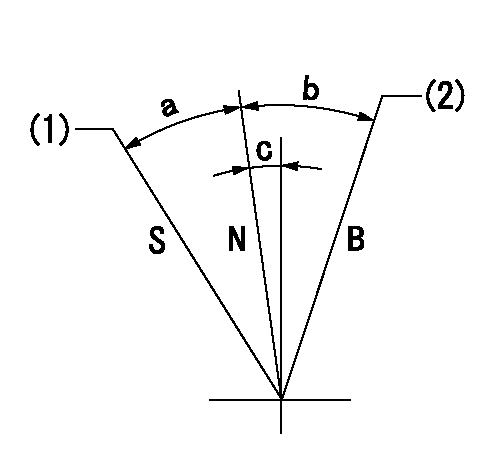

Speed control lever angle

N:Normal

B:When boosted

S:Stop

(1)Rack position = aa

(2)Rack position corresponding to bb

----------

aa=(1.8)mm bb=18mm

----------

a=20.5deg+-3deg b=11.5deg+-5deg c=0.5deg+-5deg

----------

aa=(1.8)mm bb=18mm

----------

a=20.5deg+-3deg b=11.5deg+-5deg c=0.5deg+-5deg

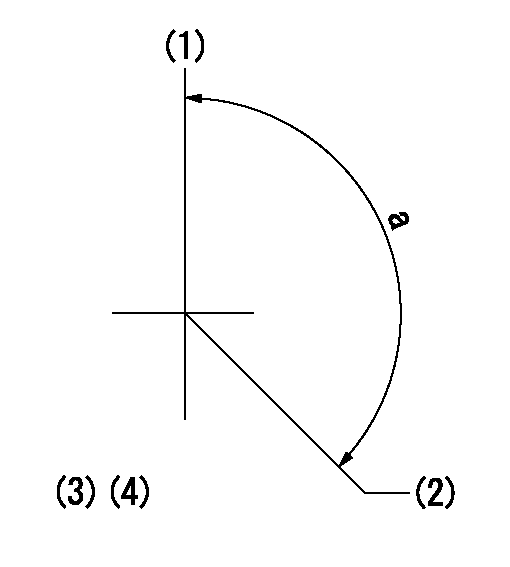

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'Y' at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(130deg)

----------

----------

a=(130deg)

Information:

March 21, 2006

U-89

A-70

D-67

O-77

Beforeor

after failureParts stock action needed PRODUCT SUPPORT PROGRAM FOR REPLACINGTHE FUEL INJECTION PUMP VOLTAGE LOAD PROTECTION CONTROL ON CERTAIN 924G,928G, AND 930G WHEEL LOADERS

12881251 PS41980

This Program can be administered eitherbefore or after failure. In either case the decision whether to apply theProgram is made by the dealer. When reporting the repair, use "PS41980"as the Part number and "7755" as the Group Number. If administered beforefailure, use "56" as the Warranty Claim Description Code and use "T" asthe SIMS Description Code. If administered after failure, use "96" as theWarranty Claim Description Code and use "Z" as the SIMS Description Code. Although this Program is to be administeredas described above on the Affected Product, parts should be removed fromparts stock as soon as possible. The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst.TERMINATION DATE

March 31, 2007PROBLEM

Voltage Load Protection Module may fail due tomoisture entry resulting in unexpected engine shut down.AFFECTED PRODUCT

Model IdentificationNumber

924G DDA375-378,380-780, 782-1538, 1540-1953, 1955-2090, 2093-2105, 2107, 2108, 2111-2113,2115, 2117, 2119-2121, 2125, 2133-2134, 2136, 2201, 2272, 2622, 2627, 2642DFZ350-381, 383-563RBB175-977, 979-982, 984-985RTA150-476, 478, 480WGX285-842WMB295-895

928G DJD323-711,713-972, 974-1179, 1181-1418, 1420-1479, 1481-1577, 1579-1662, 1664-1811,1813-1934, 1936-1939, 1941-1943, 1949, 2315, 2322WLG265-809

IT28G DBT345-1489,1491-1676EWF100-421WAC275-622

930G TFW150-193TWR233-286, 288-637, 639-642, 644,646-669, 671-675, 677-678, 680-681, 683, 685-686, 689-691, 693-697, 699,701-703, 708-711, 713-716, 718, 721-723, 725-726, 729, 731-735, 737-738,740-741, 745, 747, 750-751, 754, 758, 761-764, 767, 769, 772, 774, 777,779-782, 789-791, 793, 800-801, 805-806, 809, 811, 830-831, 864, 874, 878,905, 921, 927-928, 1295, 1634PARTS NEEDED

Qty

Part Number Description

1 2705322 CONTROL GPACTION REQUIRED

***** Parts Stock *****Remove all 2159430 Control Groups from partsstock.***** Affected Product *****Replace 2159430 with 2705322 and confirm theengine operates.SERVICE CLAIM ALLOWANCES

***** Parts Stock *****Submit one claim for all 2159430 Control Groupsremoved from parts stock.***** Affected Product *****

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts Labor Hrs Parts Labor Hrs Parts Labor Hrs

0-3000

0-24 mos 100% 1.0 0 0 0 0

3001 - 5000

25 ? 36 mos 33.3% 0.5 0 0 50% 0.5

This is a 1.0 hr job.PARTS DISPOSITION

Handle the parts in accordance with your WarrantyBulletin on warranty parts handling.

U-89

A-70

D-67

O-77

Beforeor

after failureParts stock action needed PRODUCT SUPPORT PROGRAM FOR REPLACINGTHE FUEL INJECTION PUMP VOLTAGE LOAD PROTECTION CONTROL ON CERTAIN 924G,928G, AND 930G WHEEL LOADERS

12881251 PS41980

This Program can be administered eitherbefore or after failure. In either case the decision whether to apply theProgram is made by the dealer. When reporting the repair, use "PS41980"as the Part number and "7755" as the Group Number. If administered beforefailure, use "56" as the Warranty Claim Description Code and use "T" asthe SIMS Description Code. If administered after failure, use "96" as theWarranty Claim Description Code and use "Z" as the SIMS Description Code. Although this Program is to be administeredas described above on the Affected Product, parts should be removed fromparts stock as soon as possible. The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst.TERMINATION DATE

March 31, 2007PROBLEM

Voltage Load Protection Module may fail due tomoisture entry resulting in unexpected engine shut down.AFFECTED PRODUCT

Model IdentificationNumber

924G DDA375-378,380-780, 782-1538, 1540-1953, 1955-2090, 2093-2105, 2107, 2108, 2111-2113,2115, 2117, 2119-2121, 2125, 2133-2134, 2136, 2201, 2272, 2622, 2627, 2642DFZ350-381, 383-563RBB175-977, 979-982, 984-985RTA150-476, 478, 480WGX285-842WMB295-895

928G DJD323-711,713-972, 974-1179, 1181-1418, 1420-1479, 1481-1577, 1579-1662, 1664-1811,1813-1934, 1936-1939, 1941-1943, 1949, 2315, 2322WLG265-809

IT28G DBT345-1489,1491-1676EWF100-421WAC275-622

930G TFW150-193TWR233-286, 288-637, 639-642, 644,646-669, 671-675, 677-678, 680-681, 683, 685-686, 689-691, 693-697, 699,701-703, 708-711, 713-716, 718, 721-723, 725-726, 729, 731-735, 737-738,740-741, 745, 747, 750-751, 754, 758, 761-764, 767, 769, 772, 774, 777,779-782, 789-791, 793, 800-801, 805-806, 809, 811, 830-831, 864, 874, 878,905, 921, 927-928, 1295, 1634PARTS NEEDED

Qty

Part Number Description

1 2705322 CONTROL GPACTION REQUIRED

***** Parts Stock *****Remove all 2159430 Control Groups from partsstock.***** Affected Product *****Replace 2159430 with 2705322 and confirm theengine operates.SERVICE CLAIM ALLOWANCES

***** Parts Stock *****Submit one claim for all 2159430 Control Groupsremoved from parts stock.***** Affected Product *****

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts Labor Hrs Parts Labor Hrs Parts Labor Hrs

0-3000

0-24 mos 100% 1.0 0 0 0 0

3001 - 5000

25 ? 36 mos 33.3% 0.5 0 0 50% 0.5

This is a 1.0 hr job.PARTS DISPOSITION

Handle the parts in accordance with your WarrantyBulletin on warranty parts handling.

Have questions with 101631-9600?

Group cross 101631-9600 ZEXEL

Nissan-Diesel

101631-9600

16700C6809

INJECTION-PUMP ASSEMBLY

SD33

SD33