Information injection-pump assembly

BOSCH

F 01G 09U 1HV

f01g09u1hv

ZEXEL

101609-9360

1016099360

MITSUBISHI-HEAV

3436511010

3436511010

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

101609-9360 201-3780 10R-7651 10R7651 Diesel Fuel Injection Pump Suitable for Caterpillar CAT 3066 S6K Engine 320B 320C Excavator

OfkZynodor Part Name:Diesel Fuel Injection Pump || Part Number:101609-9360 201-3780 10R-7651 10R7651 || Application:Suitable for Caterpillar CAT 3066 S6K Engine 320B 320C Excavator || Please make sure to carefully compare the photos and check the part numbers before making the purchase. If you are unable to confirm your engine model or part number, please leave us a message and we will assist you in confirming that the product you purchase is the one you need. || Your order is not merely a single purchase but the beginning of a cooperative journey, aiming to ensure the safe and smooth operation of your vehicle. We are proud to offer you reliable precision engineering components and unparalleled services.

OfkZynodor Part Name:Diesel Fuel Injection Pump || Part Number:101609-9360 201-3780 10R-7651 10R7651 || Application:Suitable for Caterpillar CAT 3066 S6K Engine 320B 320C Excavator || Please make sure to carefully compare the photos and check the part numbers before making the purchase. If you are unable to confirm your engine model or part number, please leave us a message and we will assist you in confirming that the product you purchase is the one you need. || Your order is not merely a single purchase but the beginning of a cooperative journey, aiming to ensure the safe and smooth operation of your vehicle. We are proud to offer you reliable precision engineering components and unparalleled services.

Compatible with Caterpillar CAT Engine 3066 S6K Excavator 320D 320C 321C 323D 320DL Fuel Injection Pump 212-8559 106675-4900 101609-9360

KoovDem Part Number: 212-8559 106675-4900 101609-9360 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Part Name: Fuel Injection Pump || Engine Model: 3066 is a robust and efficient engine ideal for industrial and heavy-duty use. Known for its high horsepower and torque output, it is suitable for construction equipment, generators, and marine vessels. With superior fuel efficiency and low emissions, it is a popular choice for businesses seeking a cost-effective and eco-friendly power solution. Engine Model: 3066 delivers exceptional performance and reliability in tough operating conditions on land or at sea. || Suitable for use with Caterpillar CAT Engine 3066 S6K and various models of excavators including 320D, 320C, 321C, 323D, and 320DL. || Package includes: 1 piece of Fuel Injection Pump 212-8559 106675-4900 101609-9360.

KoovDem Part Number: 212-8559 106675-4900 101609-9360 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Part Name: Fuel Injection Pump || Engine Model: 3066 is a robust and efficient engine ideal for industrial and heavy-duty use. Known for its high horsepower and torque output, it is suitable for construction equipment, generators, and marine vessels. With superior fuel efficiency and low emissions, it is a popular choice for businesses seeking a cost-effective and eco-friendly power solution. Engine Model: 3066 delivers exceptional performance and reliability in tough operating conditions on land or at sea. || Suitable for use with Caterpillar CAT Engine 3066 S6K and various models of excavators including 320D, 320C, 321C, 323D, and 320DL. || Package includes: 1 piece of Fuel Injection Pump 212-8559 106675-4900 101609-9360.

Fits For Caterpillar CAT Engine 3066 Fuel Injection Pump 212-8559 106675-4900 101609-9360 S6K Excavator 320D 320C 321C 323D 320DL

KoovDem Part Number:4938351 10404536024P || Part Name: Fuel Injection Pump || The package includes a single Fuel Injection Pump with the part number 4938351 10404536024P.

KoovDem Part Number:4938351 10404536024P || Part Name: Fuel Injection Pump || The package includes a single Fuel Injection Pump with the part number 4938351 10404536024P.

You can express buy:

USD 1454.68

29-04-2025

29-04-2025

101609-9170 Fuel Injection Pump S6K 3066 E320CL Engine Injection Pump 1253018 101609-9360 For Caterpillar Excavator

Service parts 101609-9360 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

17.7(180)

15.

NOZZLE SET

Cross reference number

BOSCH

F 01G 09U 1HV

f01g09u1hv

ZEXEL

101609-9360

1016099360

MITSUBISHI-HEAV

3436511010

3436511010

Zexel num

Bosch num

Firm num

Name

101609-9360

F 01G 09U 1HV

3436511010 MITSUBISHI-HEAV

INJECTION-PUMP ASSEMBLY

S6K-T K

S6K-T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.55

3.5

3.6

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.8

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

120.5

119.5

121.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.8+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

9.5

8.2

10.8

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

10++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

125

125

130

Fixing the lever

*

Rack limit

*

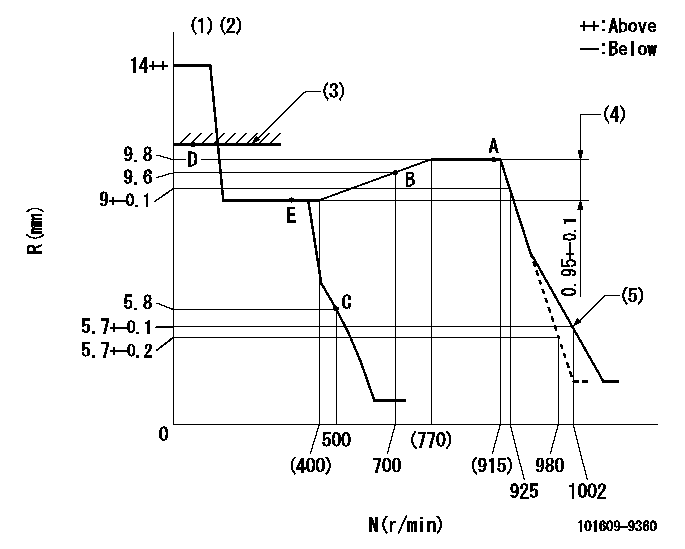

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Rack difference between N = N1 and N = N2

(5)Set idle sub-spring

----------

K=5 N1=900r/min N2=350r/min

----------

----------

K=5 N1=900r/min N2=350r/min

----------

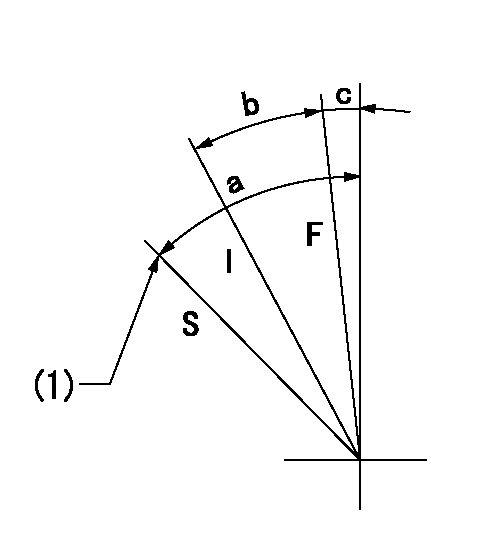

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Stopper bolt setting

----------

----------

a=31deg+-3deg b=12deg+-5deg c=6deg+-5deg

----------

----------

a=31deg+-3deg b=12deg+-5deg c=6deg+-5deg

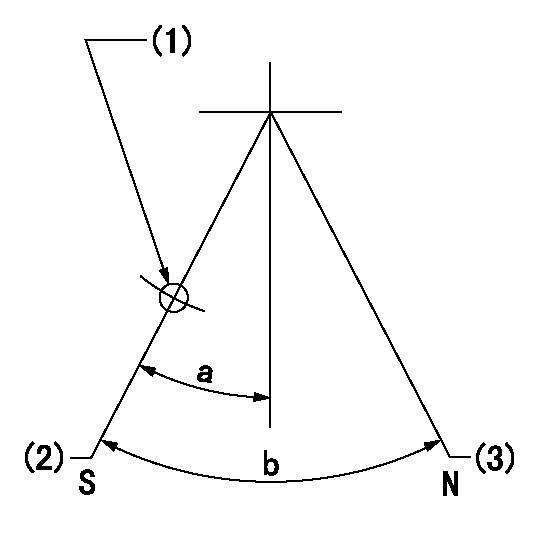

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Speed = bb, rack position = cc (sealed at delivery)

(3)Normal

----------

aa=25mm bb=0r/min cc=1-0.5mm

----------

a=21deg+-5deg b=(55deg)

----------

aa=25mm bb=0r/min cc=1-0.5mm

----------

a=21deg+-5deg b=(55deg)

0000001501 I/P WITH LOAD PLUNGER ADJ

Load plunger-equipped pump adjustment

1. Adjust the variation between cylinders and the injection quantity.

2. At Full point A, adjust the pre-stroke to the specified value.

3. After pre-stroke adjustment, reconfirm that the fuel injection quantity and the variation between cylinders is as specified.

----------

----------

----------

----------

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '3' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)After adjusting the injection quantity, adjust at rack position bb.

----------

aa=6deg bb=(9.8)mm

----------

a=(110deg)

----------

aa=6deg bb=(9.8)mm

----------

a=(110deg)

Information:

Problem

Some fuel injectors may fail on certain Challenger 75 Tractors and 3176 Truck Engines.

Affected Product

Model & Identification Number

Challenger 75 (4CJ1-406)

3176 (2YG1-Up; 7LG1-4822)

Parts Needed

Use the following parts in quantities needed to perform repairs. The application of each injector listed is noted. Use remanufactured injectors, unless unavailable.

0R3397 Injector Grp. (4P9510 if reman unavailable for 7LG 250-300 HP)0R3398 Injector Grp. (4P9520 if reman unavailable for 7LG 325 HP and 4CJ)0R3399 Injector Grp. (4P9610 if reman unavailable for 2YG 250-275 HP)0R3400 Injector Grp. (4P9620 if reman unavailable for 2YG 300-325 HP)9X7557 Seal (injector upper O-ring)9X7722 Seal (injector lower O-ring)336044 Seal (injector thrust-pad-retaining O-ring)Action Required

1. Isolate the injector which is causing the problem. Some failure modes require duplication of the conditions where the customer say the problem occurs (i.e. at full load, idle, high speed, low speed, etc.)2. Replace injectors only after verifying a problem using the 1U6661 Unit Injector Tester, cutting out cylinders, etc. Replace any failed injectors according to the rework procedures attached.Service Claim Allowances

This is a 2.5-hour job. Add 0.2 hours for 1st injector diagnostic test and 0.1 hours for each additional injector test. Add 1.2 hours for first injector sleeve replaced and 0.7 hours for each additional sleeve replaced.

3176 Truck Engines

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Attach. (1-Rework Procedure)Rework Procedure

1. Drain fuel from the cylinder head and fuel manifold. Remove air inlet piping, valve covers and Jake Brake (if equipped) , rocker arm assemblies, and injector hold down bolts. Remove the suspect injector(s) for inspection and test. Mark each injector to denote the cylinder from which it was removed. It is important to install the injector(s) into the same cylinder to prevent combustion gas leaks.2. Test the injector(s) using the 1U6661 Unit Injector Tester. Check for leaks, VOP, and spray pattern. Replace all injectors which do not pass these test.Procedure For Installing The Following Injector Part Numbers:

4P1410, 4P1420, 4P2810, 4P2820, 0R3177, AND 0R3178

1. Inspect the raised edge on the injector cone for signs of damage. If any nicks or dings are present, do not reuse the injector.2. Ream the sleeves before installing the injectors. Ream only until the sleeve has been cut to provide a full length concentric taper past the injector/sleeve sealing interface. Full removal of the indentation created by the cone step edge is not necessary.3. Install new O-rings on the injector and apply STP ® to prevent cutting during installation.4. Install the injectors, apply 6V4876 Molykote to the hold-down bolt threads and tighten the bolts to 33 NM (24 ft. lb.). Make sure the longer 5P8347 Bolts and 4P8525 Spacers (or 8T0100 Bolts and 4P1711 Spacers) are used.5. Inspect bridge assemblies for wear.Procedures For Installing All Other Injectors:

1. Ream the sleeves before installing the injectors. Ream only until the sleeves have been cut to provide a full length concentric taper past the injector/sleeve sealing interface.2. After reaming, apply a thin coating of liquid machinist's blue (Dykem) to the bottom of the sleeves - allow to dry. Install injector without

Some fuel injectors may fail on certain Challenger 75 Tractors and 3176 Truck Engines.

Affected Product

Model & Identification Number

Challenger 75 (4CJ1-406)

3176 (2YG1-Up; 7LG1-4822)

Parts Needed

Use the following parts in quantities needed to perform repairs. The application of each injector listed is noted. Use remanufactured injectors, unless unavailable.

0R3397 Injector Grp. (4P9510 if reman unavailable for 7LG 250-300 HP)0R3398 Injector Grp. (4P9520 if reman unavailable for 7LG 325 HP and 4CJ)0R3399 Injector Grp. (4P9610 if reman unavailable for 2YG 250-275 HP)0R3400 Injector Grp. (4P9620 if reman unavailable for 2YG 300-325 HP)9X7557 Seal (injector upper O-ring)9X7722 Seal (injector lower O-ring)336044 Seal (injector thrust-pad-retaining O-ring)Action Required

1. Isolate the injector which is causing the problem. Some failure modes require duplication of the conditions where the customer say the problem occurs (i.e. at full load, idle, high speed, low speed, etc.)2. Replace injectors only after verifying a problem using the 1U6661 Unit Injector Tester, cutting out cylinders, etc. Replace any failed injectors according to the rework procedures attached.Service Claim Allowances

This is a 2.5-hour job. Add 0.2 hours for 1st injector diagnostic test and 0.1 hours for each additional injector test. Add 1.2 hours for first injector sleeve replaced and 0.7 hours for each additional sleeve replaced.

3176 Truck Engines

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Attach. (1-Rework Procedure)Rework Procedure

1. Drain fuel from the cylinder head and fuel manifold. Remove air inlet piping, valve covers and Jake Brake (if equipped) , rocker arm assemblies, and injector hold down bolts. Remove the suspect injector(s) for inspection and test. Mark each injector to denote the cylinder from which it was removed. It is important to install the injector(s) into the same cylinder to prevent combustion gas leaks.2. Test the injector(s) using the 1U6661 Unit Injector Tester. Check for leaks, VOP, and spray pattern. Replace all injectors which do not pass these test.Procedure For Installing The Following Injector Part Numbers:

4P1410, 4P1420, 4P2810, 4P2820, 0R3177, AND 0R3178

1. Inspect the raised edge on the injector cone for signs of damage. If any nicks or dings are present, do not reuse the injector.2. Ream the sleeves before installing the injectors. Ream only until the sleeve has been cut to provide a full length concentric taper past the injector/sleeve sealing interface. Full removal of the indentation created by the cone step edge is not necessary.3. Install new O-rings on the injector and apply STP ® to prevent cutting during installation.4. Install the injectors, apply 6V4876 Molykote to the hold-down bolt threads and tighten the bolts to 33 NM (24 ft. lb.). Make sure the longer 5P8347 Bolts and 4P8525 Spacers (or 8T0100 Bolts and 4P1711 Spacers) are used.5. Inspect bridge assemblies for wear.Procedures For Installing All Other Injectors:

1. Ream the sleeves before installing the injectors. Ream only until the sleeves have been cut to provide a full length concentric taper past the injector/sleeve sealing interface.2. After reaming, apply a thin coating of liquid machinist's blue (Dykem) to the bottom of the sleeves - allow to dry. Install injector without

Have questions with 101609-9360?

Group cross 101609-9360 ZEXEL

Mitsubishi-Heav

Dpico

Mitsubishi-Heav

101609-9360

F 01G 09U 1HV

3436511010

INJECTION-PUMP ASSEMBLY

S6K-T

S6K-T