Information injection-pump assembly

BOSCH

9 400 612 210

9400612210

ZEXEL

101609-9033

1016099033

MITSUBISHI-HEAV

3436105072

3436105072

Rating:

Service parts 101609-9033 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

101609-9033

as INJECTION-PUMP ASSEMBLY

Include in #2:

104278-1030

as _

Cross reference number

BOSCH

9 400 612 210

9400612210

ZEXEL

101609-9033

1016099033

MITSUBISHI-HEAV

3436105072

3436105072

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.8

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

98

97

99

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.8+-0.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

96

92

100

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

6+-0.5

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

12

10.7

13.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

F

Rack position

9++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

95

100

Fixing the lever

*

Rack limit

*

Test data Ex:

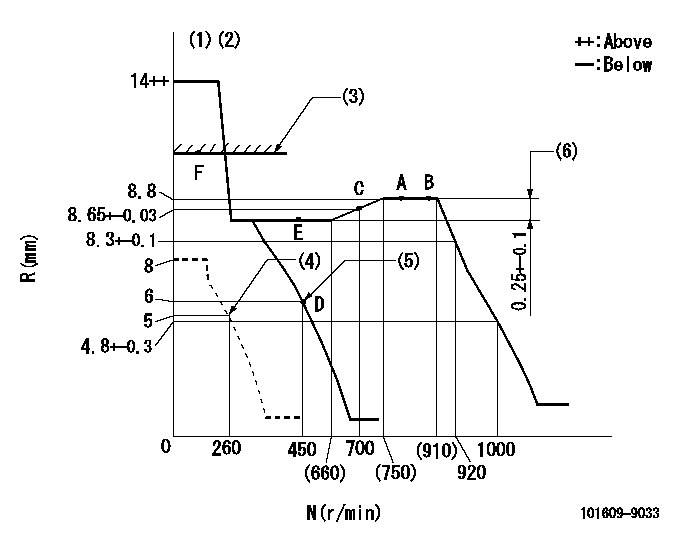

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

----------

K=15 N1=850r/min N2=400r/min

----------

----------

K=15 N1=850r/min N2=400r/min

----------

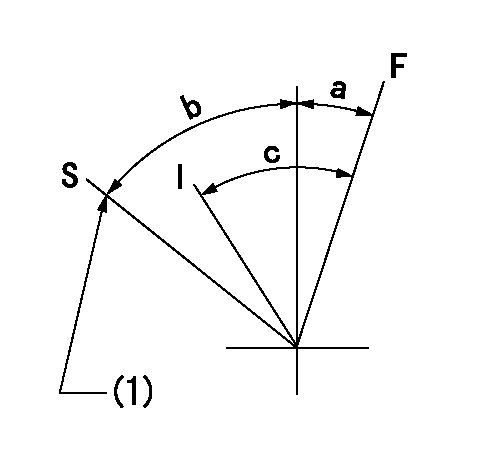

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Stopper bolt setting

----------

----------

a=3deg+-5deg b=31deg+-3deg c=14deg+-5deg

----------

----------

a=3deg+-5deg b=31deg+-3deg c=14deg+-5deg

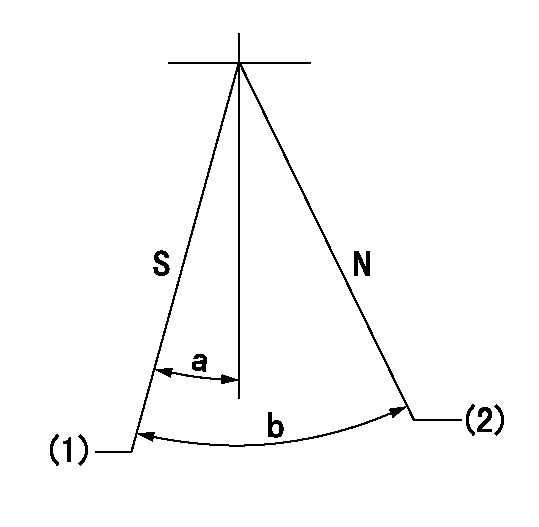

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa, speed = bb.

(2)Normal

----------

aa=1-0.5mm bb=0r/min

----------

a=21deg+-5deg b=(55deg)

----------

aa=1-0.5mm bb=0r/min

----------

a=21deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

1. Remove nuts (1), cover (2), and the gasket. 2. Put No. 1 piston at the top center compression position (TC) with the following procedure:a. Remove plug (3), two bolts and cover (2) from the flywheel housing. b. Install Tool (B) in the flywheel housing. Use Tool (B) to slowly rotate the engine in the direction of normal rotation, (counterclockwise as seen from the flywheel end of the engine), until timing bolt (4) can be installed in the flywheel housing and into the hole in the flywheel. c. Remove the valve cover from the valve cover base. Check to see if both rocker arms (5) for the No. 1 cylinder can be moved backward and forward. The No. 1 piston is at the top center compression position (TC) when the timing bolt is installed in the flywheel and both rocker arms for the No. 1 cylinder can be moved backward and forward. If both rocker arms cannot be moved, the No. 1 piston is not at the top center compression position (TC). Remove the timing bolt from the flywheel and rotate the engine in the direction for normal rotation, (counterclockwise as seen from the flywheel end of the engine one full turn 360 degrees, and install the timing bolt again.3. Remove the timing bolt, and use Tool (B) to rotate the engine in the opposite direction of normal rotation (clockwise as seen from the flywheel end of the engine) a minimum of 30 degrees. The timing is correct if Tool (A) and the timing bolt can be installed at the same time. The timing procedure in the Testing & Adjustment Manual must be done again if the timing bolt and Tool (A) can not be installed at the same time.4. Remove the plug from the timing pin hole in the fuel injection pump housing. Install Tool (A) in the timing pin hole. 5. Remove eight bolts (6) and automatic timing advance (7). 6. Remove gear (9) from fuel injection pump camshaft (8).The following steps are for the installation procedure.7. Install gear (9) on fuel injection pump camshaft (8). 8. Install two 3/8 in 16 NC x 6 in (152.4 mm) long guide bolts (10). Space the guide bolts evenly.

There is a light spring located beneath the flyweight cover (12). Hold cover (12) while removing last nut (11). Slowly remove flyweight cover (12) to avoid dropping the spring.

9. Remove four nuts (11) and remove flyweight cover (12). 10. Put automatic timing advance (13) in position on the fuel injection pump camshaft, and install four bolts (14). Tighten bolts (14) just past finger tight. Remove guide bolts (15). 11. Install four nuts (16). Install Tool (C). 12. Tighten four knurled nuts (17) finger tight.

Do not use any tools to tighten the knurled nuts.

13. Install all mounting bolts (14) and tighten to 55 10 N m (41 7 lb ft).14. Loosen knurled nuts (17). Remove four nuts (16) and remove Tool (C).15. Install the spring and flyweight cover

There is a light spring located beneath the flyweight cover (12). Hold cover (12) while removing last nut (11). Slowly remove flyweight cover (12) to avoid dropping the spring.

9. Remove four nuts (11) and remove flyweight cover (12). 10. Put automatic timing advance (13) in position on the fuel injection pump camshaft, and install four bolts (14). Tighten bolts (14) just past finger tight. Remove guide bolts (15). 11. Install four nuts (16). Install Tool (C). 12. Tighten four knurled nuts (17) finger tight.

Do not use any tools to tighten the knurled nuts.

13. Install all mounting bolts (14) and tighten to 55 10 N m (41 7 lb ft).14. Loosen knurled nuts (17). Remove four nuts (16) and remove Tool (C).15. Install the spring and flyweight cover