Information injection-pump assembly

BOSCH

9 400 612 209

9400612209

ZEXEL

101609-9021

1016099021

MITSUBISHI-HEAV

3436105062

3436105062

Rating:

Service parts 101609-9021 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

101609-9021

as INJECTION-PUMP ASSEMBLY

Include in #2:

104278-3000

as _

Cross reference number

BOSCH

9 400 612 209

9400612209

ZEXEL

101609-9021

1016099021

MITSUBISHI-HEAV

3436105062

3436105062

Zexel num

Bosch num

Firm num

Name

101609-9021

9 400 612 209

3436105062 MITSUBISHI-HEAV

INJECTION-PUMP ASSEMBLY

S6K-T K

S6K-T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.8

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

98

97

99

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

(8.8)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

96

92

100

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

6+-0.5

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

12

10.7

13.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

F

Rack position

9++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

95

100

Fixing the lever

*

Rack limit

*

Test data Ex:

Governor adjustment

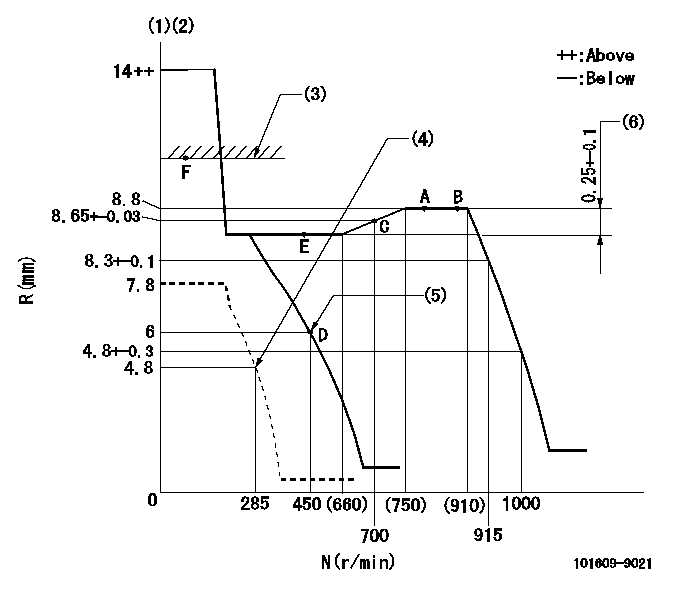

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

----------

K=15 N1=850r/min N2=400r/min

----------

----------

K=15 N1=850r/min N2=400r/min

----------

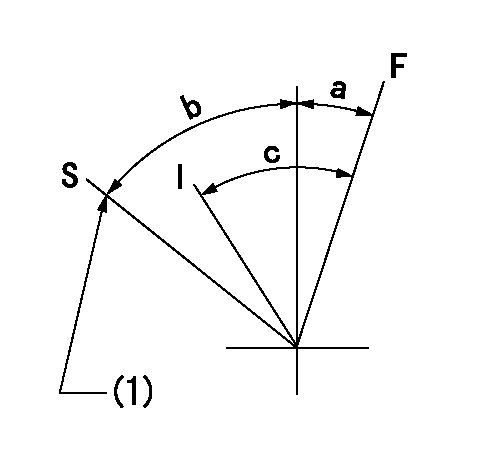

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Stopper bolt setting

----------

----------

a=2deg+-5deg b=31deg+-3deg c=16deg+-5deg

----------

----------

a=2deg+-5deg b=31deg+-3deg c=16deg+-5deg

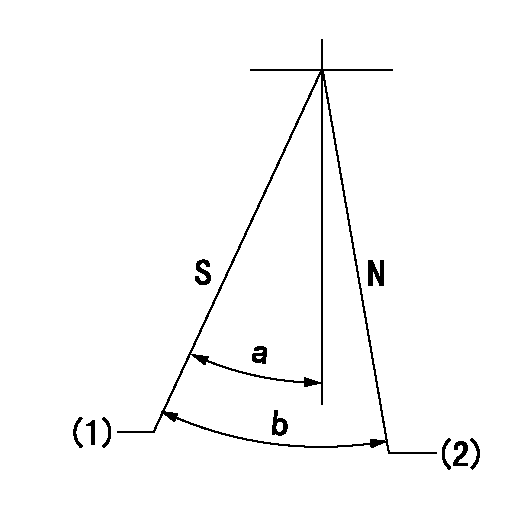

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa, speed = bb.

(2)Normal

----------

aa=1-0.5mm bb=0r/min

----------

a=21deg+-5deg b=(55deg)

----------

aa=1-0.5mm bb=0r/min

----------

a=21deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Refer to attached Rework Procedure.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 1*******

0-2000 hrs,

0-12 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

2001-5000 hrs,

13-18 mo 100.0% 50.0% 0.0% 0.0% 0.0% 50.0%

5001-8000 hrs,

19-24 mo 100.0% 30.0% 0.0% 0.0% 0.0% 70.0%

This is a 4.0-hour job for Group 1

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 2*******

0-2000 hrs,

0-12 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

2001-5000 hrs,

13-18 mo 100.0% 50.0% 0.0% 0.0% 0.0% 50.0%

5001-8000 hrs,

19-24 mo 100.0% 30.0% 0.0% 0.0% 0.0% 70.0%

This is a 4.0-hour job for Group 2

PARTS DISPOSITION

removed java code "affectDisposition"commented on Chints October 12 2006 Chints w.r.t CM000343756-->

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Rework Procedure

For the following units listed remove (6) 207-5248 Injector Rocker Arms, and replace with (6) 278-1365 Injector Rocker Arms.

For proper ?Disassembly & Assembly? instructions of the injector rocker arms please refer to the following Publications in SIS Web. (SENR9832-06 Testing & Adjusting-Finding Top Dead Center Position for No. 1 Piston), (SENR9832-06 Testing & Adjusting-Electronic Unit Injector Adjusting & Setting), and (SENR9832-06 Testing & Adjusting-Engine Valve Lash Inspect/Adjust).

Note: It is important that while installing the 278-1365 Injector Rocker Arms, that the engine is in the proper position (Top Dead Center and 180 degrees out) so the Injector Rocker Arms are properly adjusted and set. It is also important that during the installation of the Injector Rocker Arms that the Exhaust Valve, and Intake Valve lash settings be inspected and if needed re-set to factory specifications.

Note: During the rework process please inspect the 6I-0901 Rocker Arm Shafts for any signs of misalignment of the stud mounting holes, wear, damage, fretting etc. If damage is found to the shaft or if fretting or damage is found with any of the through bolt/stud mounting holes, the shaft is to be replaced, and reported against this service letter as contingent damage.

Have questions with 101609-9021?

Group cross 101609-9021 ZEXEL

Mitsubishi-Heav

Mitsubishi-Heav

101609-9021

9 400 612 209

3436105062

INJECTION-PUMP ASSEMBLY

S6K-T

S6K-T