Information injection-pump assembly

ZEXEL

101609-3870

1016093870

KOMATSU

6736711180

6736711180

Rating:

Cross reference number

ZEXEL

101609-3870

1016093870

KOMATSU

6736711180

6736711180

Zexel num

Bosch num

Firm num

Name

101609-3870

6736711180 KOMATSU

INJECTION-PUMP ASSEMBLY

SA6D102E-

SA6D102E-

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.5

2.45

2.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.9

Pump speed

r/min

1175

1175

1175

Average injection quantity

mm3/st.

105

104

106

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

50.7

50.7

Boost pressure

mmHg

380

380

Hydraulic cylinder ON

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.2+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

14.5

13.5

15.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Hydraulic cylinder ON

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85

85

95

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Hydraulic cylinder OFF

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

800

800

800

Rack position

(8.75)

Boost pressure

kPa

18.7

16

21.4

Boost pressure

mmHg

140

120

160

Boost compensator adjustment_02

Pump speed

r/min

800

800

800

Rack position

10.05

Boost pressure

kPa

37.3

37.3

37.3

Boost pressure

mmHg

280

280

280

Test data Ex:

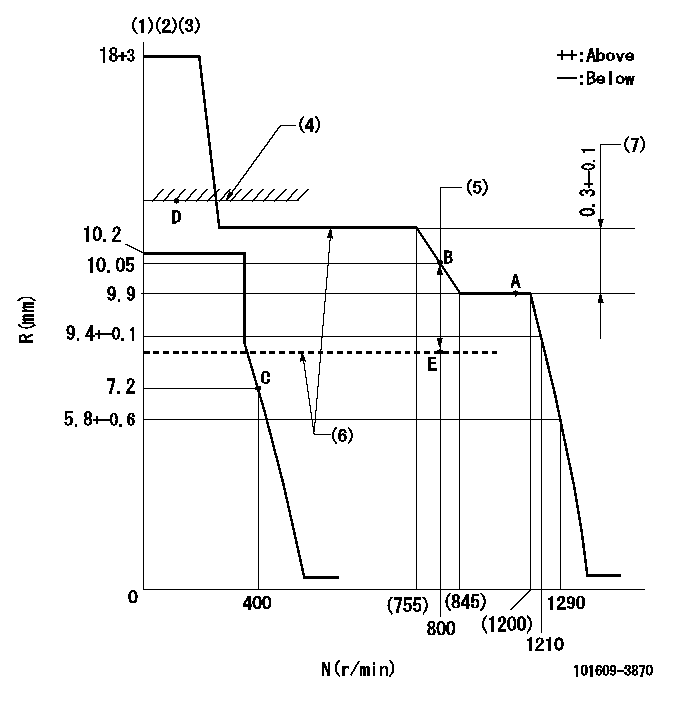

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Adjust the secondary timing before adjusting the governor.

(4)RACK LIMIT (When hydraulic cylinder is OFF)

(5)Boost compensator stroke: BCL

(6)When hydraulic cylinder ON: P1

(7)Rack difference between N = N1 and N = N2

----------

K=13 BCL=1.3+-0.1mm P1=392kPa(4kgf/cm2) N1=1175r/min N2=700r/min

----------

----------

K=13 BCL=1.3+-0.1mm P1=392kPa(4kgf/cm2) N1=1175r/min N2=700r/min

----------

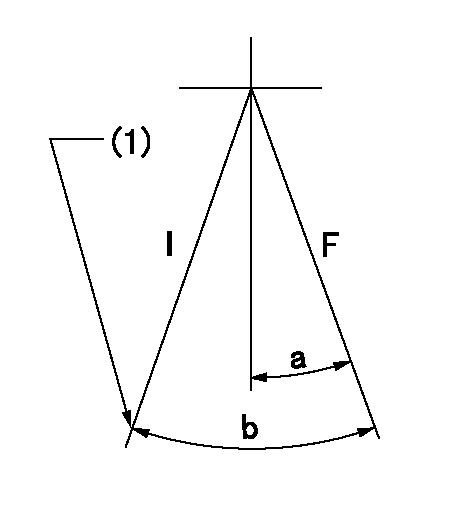

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=12deg+-5deg b=29deg+-5deg

----------

----------

a=12deg+-5deg b=29deg+-5deg

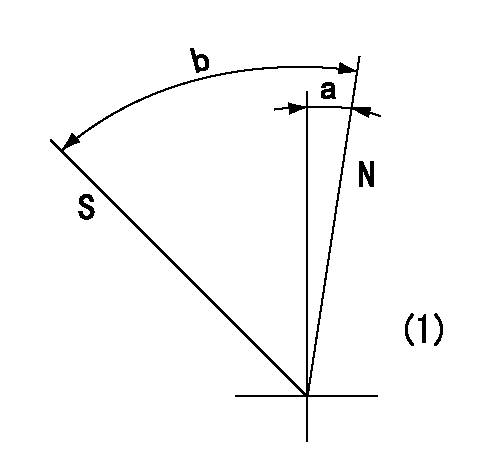

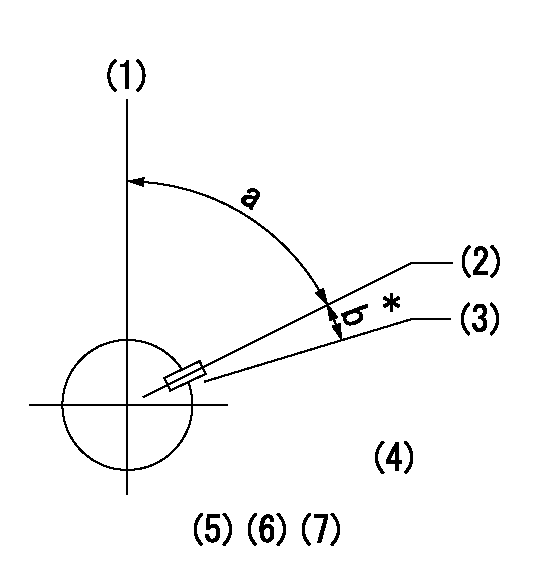

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)No return spring

----------

----------

a=0deg+-5deg b=53deg+-5deg

----------

----------

a=0deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Key groove position at No. 1 cylinder's beginning of injection position (at BTDC: aa).

(3)Position of the key groove of the No. 1 cylinder at B.T.D.C. bb (fix the governor flyweight at this position for delivery).

(4)B.T.D.C.: aa

(5)At second timing adjustment, set the camshaft at the * position and tighten the flyweight locknut.

(6)Align the flyweight's timing gear position with the lockpin groove and then fully tighten the flyweight to the camshaft.

(7)Remove the lock pin and adjust the governor. Reinstall the lock pin to fix the flyweight for delivery.

----------

aa=19.5deg bb=0deg

----------

a=54deg54min+-3deg b=9deg45min+-30min

----------

aa=19.5deg bb=0deg

----------

a=54deg54min+-3deg b=9deg45min+-30min

Information:

November 10, 2003

U-307

A-211

D-227

O-256

TT-24

TM-7

Partsstock action only PRODUCT IMPROVEMENT PROGRAM FOR REMOVINGCERTAIN REMAN FUEL INJECTORS FROM DEALER PART STOCK

7750 PI70071

The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst.TERMINATION DATE

February 29, 2004PROBLEM

Certain fuel injectors need to be removed fromdealer part stock. A number of fuel injectors were built with a Valve OpeningPressure (VOP) spacer that missed a hardening operation. This non-hardenedspacer allows premature wear, causing several operational problems whichmay include: engine misfire, low power, white smoke, and engine would notstart.ACTION REQUIRED

Only remove engine injectors within the suspectdate code range from your parts supply.

In order to perform this inspection, injectorsmust be removed from the packaging.

Repackage all injectors.

Illustration 1 (3406E, C15) Illustration 2 (C10, C12)SERVICE CLAIM ALLOWANCES

Submit one claim for all 0R4667, 0R4893, 0R4894,0R4895, 0R9256, 0R9257, 0R9258, 0R9259, 0R9803, 0R4986, 0R4987, 0R4988,0R7549, 0R8773, 0R8780, and 0R9530 removed from parts stock. Remove onlythose injectors from the suspect serial number range listed below. 0R4667, 0R4893, 0R4894, 0R4895, 0R9256,0R9257, 0R9258, 0R9259, and 0R9803 3406E and C15 injectors should be removedif the serial number is between 318224-371662. 0R4986, 0R4987, 0R4988, 0R7549, 0R8773,0R8780, and 0R9530 C10 and C12 injectors should be removed if the serialnumber is between 34768-47935.PARTS DISPOSITION

These remanufactured parts need to be returnedwith dealer normal core returns in order to allow for core deposit refund.

U-307

A-211

D-227

O-256

TT-24

TM-7

Partsstock action only PRODUCT IMPROVEMENT PROGRAM FOR REMOVINGCERTAIN REMAN FUEL INJECTORS FROM DEALER PART STOCK

7750 PI70071

The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst.TERMINATION DATE

February 29, 2004PROBLEM

Certain fuel injectors need to be removed fromdealer part stock. A number of fuel injectors were built with a Valve OpeningPressure (VOP) spacer that missed a hardening operation. This non-hardenedspacer allows premature wear, causing several operational problems whichmay include: engine misfire, low power, white smoke, and engine would notstart.ACTION REQUIRED

Only remove engine injectors within the suspectdate code range from your parts supply.

In order to perform this inspection, injectorsmust be removed from the packaging.

Repackage all injectors.

Illustration 1 (3406E, C15) Illustration 2 (C10, C12)SERVICE CLAIM ALLOWANCES

Submit one claim for all 0R4667, 0R4893, 0R4894,0R4895, 0R9256, 0R9257, 0R9258, 0R9259, 0R9803, 0R4986, 0R4987, 0R4988,0R7549, 0R8773, 0R8780, and 0R9530 removed from parts stock. Remove onlythose injectors from the suspect serial number range listed below. 0R4667, 0R4893, 0R4894, 0R4895, 0R9256,0R9257, 0R9258, 0R9259, and 0R9803 3406E and C15 injectors should be removedif the serial number is between 318224-371662. 0R4986, 0R4987, 0R4988, 0R7549, 0R8773,0R8780, and 0R9530 C10 and C12 injectors should be removed if the serialnumber is between 34768-47935.PARTS DISPOSITION

These remanufactured parts need to be returnedwith dealer normal core returns in order to allow for core deposit refund.

Have questions with 101609-3870?

Group cross 101609-3870 ZEXEL

Komatsu

Komatsu

Komatsu

101609-3870

6736711180

INJECTION-PUMP ASSEMBLY

SA6D102E-

SA6D102E-