Information injection-pump assembly

BOSCH

9 400 615 911

9400615911

ZEXEL

101609-3551

1016093551

KOMATSU

3863966

3863966

Rating:

Cross reference number

BOSCH

9 400 615 911

9400615911

ZEXEL

101609-3551

1016093551

KOMATSU

3863966

3863966

Zexel num

Bosch num

Firm num

Name

101609-3551

9 400 615 911

3863966 KOMATSU

INJECTION-PUMP ASSEMBLY

SA6D102E K

SA6D102E K

101609-3551

9 400 615 911

6736711310 KOMATSU

INJECTION-PUMP ASSEMBLY

SA6D102E K

SA6D102E K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.5

2.45

2.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.9

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

143.5

142

145

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.6+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

9

8

10

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

11.1++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

120

120

130

Fixing the lever

*

Rack limit

*

Test data Ex:

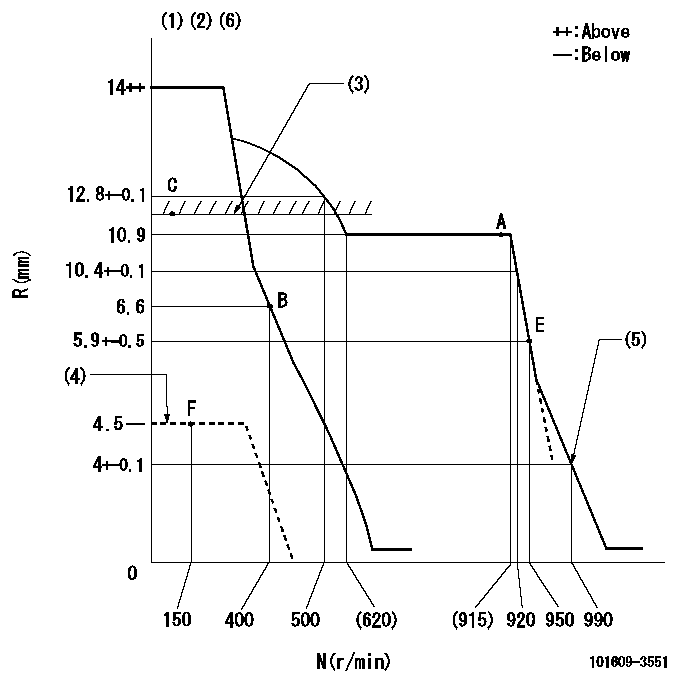

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Stop lever at stopping (with the speed lever at full)

(5)Set idle sub-spring

(6)Adjust the secondary timing before adjusting the governor.

----------

K=14

----------

----------

K=14

----------

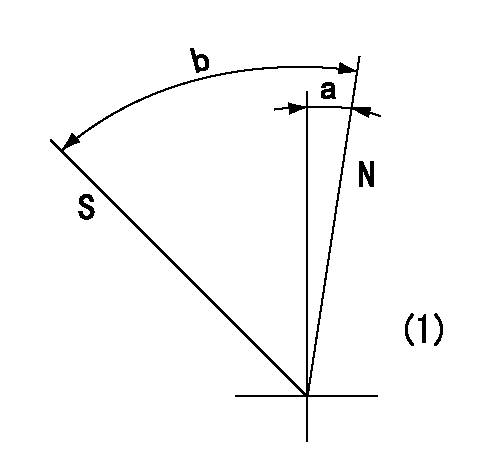

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(2deg)+-5deg b=(24deg)+-5deg

----------

----------

a=(2deg)+-5deg b=(24deg)+-5deg

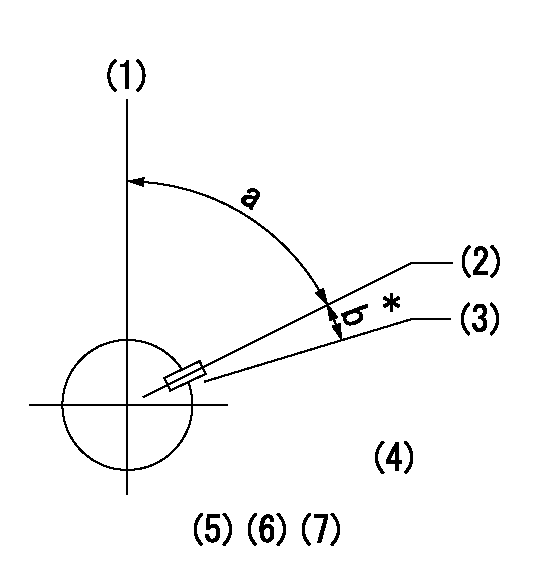

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)No return spring

----------

----------

a=0deg+-5deg b=53deg+-5deg

----------

----------

a=0deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Key groove position at No. 1 cylinder's beginning of injection position (at BTDC: aa).

(3)Position of the key groove of the No. 1 cylinder at B.T.D.C. bb (fix the governor flyweight at this position for delivery).

(4)B.T.D.C.: aa

(5)At second timing adjustment, set the camshaft at the * position and tighten the flyweight locknut.

(6)Align the flyweight's timing gear position with the lockpin groove and then fully tighten the flyweight to the camshaft.

(7)Remove the lock pin and adjust the governor. Reinstall the lock pin to fix the flyweight for delivery.

----------

aa=16deg bb=0deg

----------

a=54deg54min+-3deg b=8deg+-30min

----------

aa=16deg bb=0deg

----------

a=54deg54min+-3deg b=8deg+-30min

Information:

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

This Revised Service Letter replaces the October 20, 1993 Service Letter. Changes have been made to the Action Required.

Termination Date

January 31, 1994Problem

Certain 7N0449, 1W5829, 4W1819, 4W8483, 7W3710 and 1010060 Nozzle Assemblies need to be removed from Parts Stock because they may crack at the braze joint.

Action Required

Remove all 7N0449, 1W5829, 4W1819, 4W8483, 7W3710 and 1010060 Nozzle Assemblies from Parts Stock with a date code of D--3, E--3, F--3, or G--3. Refer to the Illustration below for the location of the date code. The date codes will appear as a letter followed by three numbers. The letter denotes the month, the first two numbers denote the day of the month, and the number 3 denotes the year. For example, D223 is the date code for April 22, 1993.

Location of Date CodeService Claim Allowances

Submit one claim for all 7N0449, 1W5829, 4W1819, 4W8483, 7W3710 and 1010060 Nozzle Assemblies removed from Parts Stock.

US and Canadian Dealers Only - When submitting a Parts Stock claim use 99Z00007 in the Product Identification Number Field.

Parts Disposition

U.S. and Canadian Dealers

Return all 7N0449, 1W5829, 4W1819, 4W8483, 7W3710 and 1010060 Nozzle Assemblies that are removed from Parts Stock and a copy of the claim to:

CaterpillarInc.

Attn:HowardJenkel/PI7324

Warehouse#4Docks7thru10

8201N.University

Peoria,IL 61615

All Other Dealers

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

This Revised Service Letter replaces the October 20, 1993 Service Letter. Changes have been made to the Action Required.

Termination Date

January 31, 1994Problem

Certain 7N0449, 1W5829, 4W1819, 4W8483, 7W3710 and 1010060 Nozzle Assemblies need to be removed from Parts Stock because they may crack at the braze joint.

Action Required

Remove all 7N0449, 1W5829, 4W1819, 4W8483, 7W3710 and 1010060 Nozzle Assemblies from Parts Stock with a date code of D--3, E--3, F--3, or G--3. Refer to the Illustration below for the location of the date code. The date codes will appear as a letter followed by three numbers. The letter denotes the month, the first two numbers denote the day of the month, and the number 3 denotes the year. For example, D223 is the date code for April 22, 1993.

Location of Date CodeService Claim Allowances

Submit one claim for all 7N0449, 1W5829, 4W1819, 4W8483, 7W3710 and 1010060 Nozzle Assemblies removed from Parts Stock.

US and Canadian Dealers Only - When submitting a Parts Stock claim use 99Z00007 in the Product Identification Number Field.

Parts Disposition

U.S. and Canadian Dealers

Return all 7N0449, 1W5829, 4W1819, 4W8483, 7W3710 and 1010060 Nozzle Assemblies that are removed from Parts Stock and a copy of the claim to:

CaterpillarInc.

Attn:HowardJenkel/PI7324

Warehouse#4Docks7thru10

8201N.University

Peoria,IL 61615

All Other Dealers

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 101609-3551?

Group cross 101609-3551 ZEXEL

Komatsu

Komatsu

Komatsu

101609-3551

9 400 615 911

3863966

INJECTION-PUMP ASSEMBLY

SA6D102E

SA6D102E

101609-3551

9 400 615 911

6736711310

INJECTION-PUMP ASSEMBLY

SA6D102E

SA6D102E