Information injection-pump assembly

BOSCH

9 400 615 908

9400615908

ZEXEL

101609-3501

1016093501

KOMATSU

3863866

3863866

Rating:

Include in #2:

104258-5142

as _

Cross reference number

BOSCH

9 400 615 908

9400615908

ZEXEL

101609-3501

1016093501

KOMATSU

3863866

3863866

Zexel num

Bosch num

Firm num

Name

101609-3501

9 400 615 908

3863866 KOMATSU

INJECTION-PUMP ASSEMBLY

S6D102E K 14BE INJECTION PUMP ASSY PE6A PE

S6D102E K 14BE INJECTION PUMP ASSY PE6A PE

101609-3501

9 400 615 908

6735711411 KOMATSU

INJECTION-PUMP ASSEMBLY

S6D102E K 14BE INJECTION PUMP ASSY PE6A PE

S6D102E K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.5

2.45

2.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

78

77

79

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.6+-0.5

Pump speed

r/min

515

515

515

Average injection quantity

mm3/st.

9

8

10

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

70

70

80

Fixing the lever

*

Rack limit

*

Test data Ex:

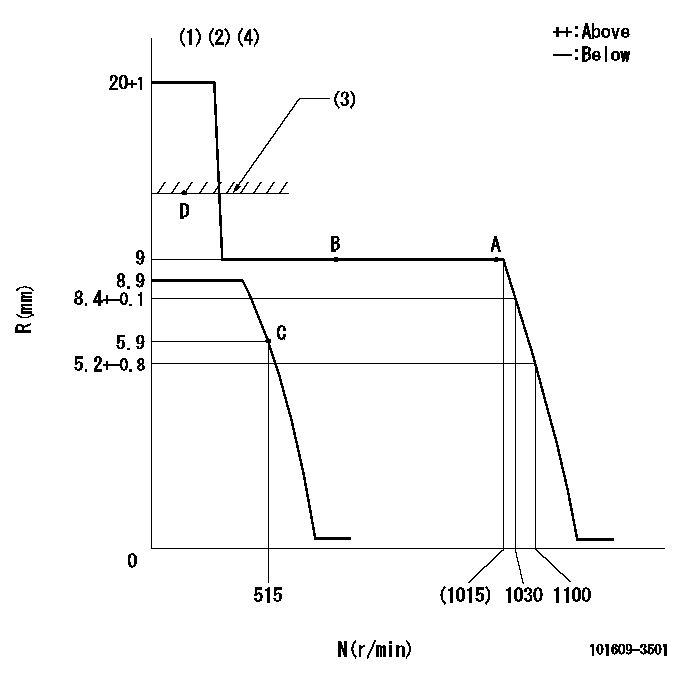

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Adjust the secondary timing before adjusting the governor.

----------

K=18

----------

----------

K=18

----------

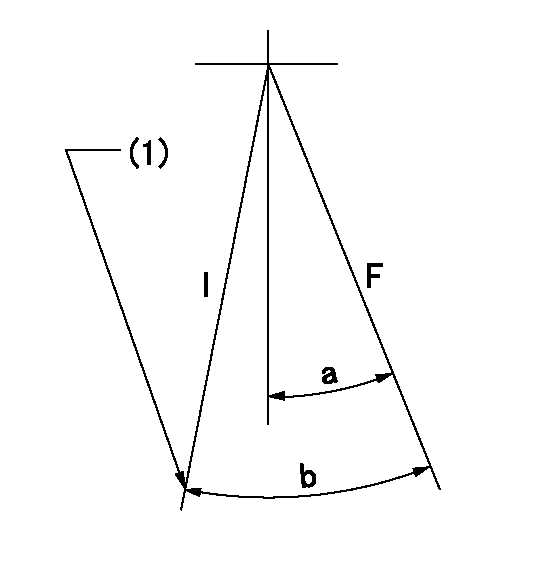

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=12deg+-5deg b=27deg+-5deg

----------

----------

a=12deg+-5deg b=27deg+-5deg

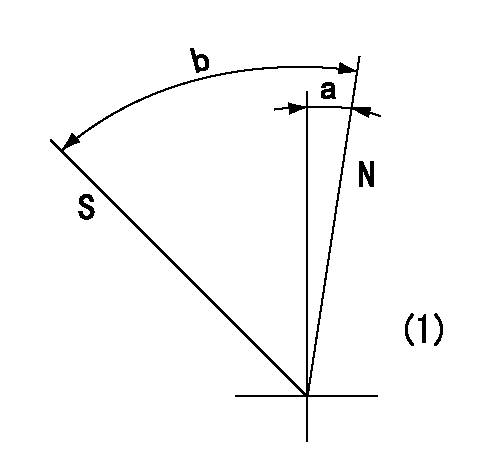

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)No return spring

----------

----------

a=0deg+-5deg b=53deg+-5deg

----------

----------

a=0deg+-5deg b=53deg+-5deg

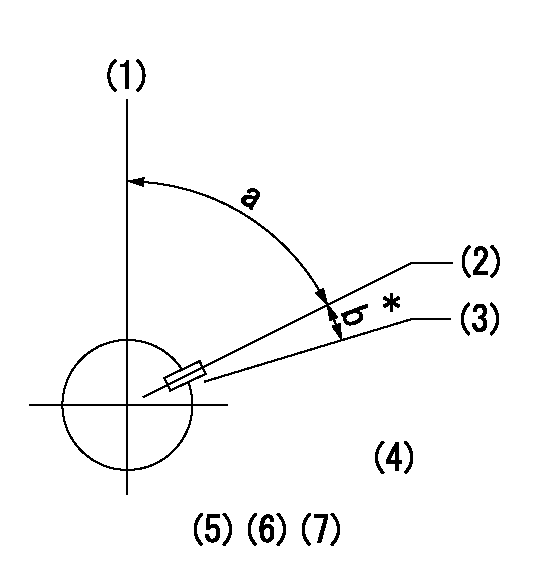

Timing setting

(1)Pump vertical direction

(2)Key groove position at No. 1 cylinder's beginning of injection position (at BTDC: aa).

(3)Position of the key groove of the No. 1 cylinder at B.T.D.C. bb (fix the governor flyweight at this position for delivery).

(4)B.T.D.C.: aa

(5)At second timing adjustment, set the camshaft at the * position and tighten the flyweight locknut.

(6)Align the flyweight's timing gear position with the lockpin groove and then fully tighten the flyweight to the camshaft.

(7)Remove the lock pin and adjust the governor. Reinstall the lock pin to fix the flyweight for delivery.

----------

aa=17deg bb=0deg

----------

a=54deg54min+-3deg b=8deg30min+-30min

----------

aa=17deg bb=0deg

----------

a=54deg54min+-3deg b=8deg30min+-30min

Information:

Group 2

1 - 6I0347 Bracket2 - 7C6591 Clamp2 - 7C7747 Clamp2 - 4B4274 Washer2 - 9N3388 Screw1 - 6I4813 Clamp Kit1 - 8T1296 Washer2 - 5P4939 Screw1 - 9Y3357 Clamp1 - 1029228 Clamp AssemblyGroup 3

2 - 5P4939 Screw1 - 9Y3357 Clamp1 - 1029228 Clamp AssemblyAction Required

See the attached procedure.

Service Claim Allowances

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Attach. (1-Rework Procedure)Rework Procedure

Refer to the following instructions and illustrations. Replace the existing fuel lines and their related parts with the new fuel line groups.

To insure correct clamp locations, install left and right fuel line groups as assembled. However, if clamps are removed, mark locations to insure correct positions when reassembling.

On the 992C Wheel Loader, it is necessary to remove the 6N8322 Air Outlet Tube Assembly to be able to install the right bank fuel line group.

Tighten the fuel line clamp screws to a torque of 2.25 N m (20 lb in). Do not over tighten. Use a 6V6069 Torque Screwdriver or similar tool to tighten the screws.

Group 1 Procedure

1. Clean and paint the new 6I0361 and 7E3539 Fuel Line Groups before proceeding to the job site.A) "Tape Off" the number 3, 5, and 6 fuel lines in the area of the tower clamp. (See Illustration 1 - Part 4 of 5, Section C-C)B) Install 5F2807 Plastic Caps and 2F2990 Plastic Plugs on the ends of the fuel lines.C) Clean and paint the fuel line groups.D) After drying completely, remove the tape. Do not remove the plastic caps and plugs until the fuel lines are ready to be installed on the engine. Transport the fuel line groups in their original boxes.2. Remove all mounting bolts from the fuel line brackets at the aftercooler housing. Except for the tower clamp assembly, new mounting bolts and washers will be used. Keep the washers. The washers may be needed later as spacers.3. A) Disassemble the tower clamp assembly behind the fuel injection pump. The 9Y3356 Clamp and 9Y3359 Clamp As. that form the tower clamp will be reused. (See Illustration 1 - Part 4 of 5, Section C-C)B) Disconnect the 2 line clamps from the 9Y3361 Bracket (Front V Bracket).C) Disconnect the 6 line clamps from the 7E5779 Bracket (Large V Bracket).4. Disconnect all the fuel lines at the fuel injection pump and at the adaptors in the valve cover bases.5. A) Remove the left and right side fuel line groups as separate assemblies.B) Remove the 9Y3361 Bracket (Front V Bracket). Replace it with a new 6I0347 Bracket.6. Remove the plastic caps and plugs from the fuel lines. Set the new 6I0361 Fuel Lines Group (left side) and the new 7E3539 Fuel Lines Group (right side) in place and hand tighten the fuel nuts. (See Illustration 1 - Part 1 of 5). If any of the ends of the individual fuel lines are not square with the bonnets in the fuel injection pump or with the adaptors in the valve cover bases, gently bend the lines

1 - 6I0347 Bracket2 - 7C6591 Clamp2 - 7C7747 Clamp2 - 4B4274 Washer2 - 9N3388 Screw1 - 6I4813 Clamp Kit1 - 8T1296 Washer2 - 5P4939 Screw1 - 9Y3357 Clamp1 - 1029228 Clamp AssemblyGroup 3

2 - 5P4939 Screw1 - 9Y3357 Clamp1 - 1029228 Clamp AssemblyAction Required

See the attached procedure.

Service Claim Allowances

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Attach. (1-Rework Procedure)Rework Procedure

Refer to the following instructions and illustrations. Replace the existing fuel lines and their related parts with the new fuel line groups.

To insure correct clamp locations, install left and right fuel line groups as assembled. However, if clamps are removed, mark locations to insure correct positions when reassembling.

On the 992C Wheel Loader, it is necessary to remove the 6N8322 Air Outlet Tube Assembly to be able to install the right bank fuel line group.

Tighten the fuel line clamp screws to a torque of 2.25 N m (20 lb in). Do not over tighten. Use a 6V6069 Torque Screwdriver or similar tool to tighten the screws.

Group 1 Procedure

1. Clean and paint the new 6I0361 and 7E3539 Fuel Line Groups before proceeding to the job site.A) "Tape Off" the number 3, 5, and 6 fuel lines in the area of the tower clamp. (See Illustration 1 - Part 4 of 5, Section C-C)B) Install 5F2807 Plastic Caps and 2F2990 Plastic Plugs on the ends of the fuel lines.C) Clean and paint the fuel line groups.D) After drying completely, remove the tape. Do not remove the plastic caps and plugs until the fuel lines are ready to be installed on the engine. Transport the fuel line groups in their original boxes.2. Remove all mounting bolts from the fuel line brackets at the aftercooler housing. Except for the tower clamp assembly, new mounting bolts and washers will be used. Keep the washers. The washers may be needed later as spacers.3. A) Disassemble the tower clamp assembly behind the fuel injection pump. The 9Y3356 Clamp and 9Y3359 Clamp As. that form the tower clamp will be reused. (See Illustration 1 - Part 4 of 5, Section C-C)B) Disconnect the 2 line clamps from the 9Y3361 Bracket (Front V Bracket).C) Disconnect the 6 line clamps from the 7E5779 Bracket (Large V Bracket).4. Disconnect all the fuel lines at the fuel injection pump and at the adaptors in the valve cover bases.5. A) Remove the left and right side fuel line groups as separate assemblies.B) Remove the 9Y3361 Bracket (Front V Bracket). Replace it with a new 6I0347 Bracket.6. Remove the plastic caps and plugs from the fuel lines. Set the new 6I0361 Fuel Lines Group (left side) and the new 7E3539 Fuel Lines Group (right side) in place and hand tighten the fuel nuts. (See Illustration 1 - Part 1 of 5). If any of the ends of the individual fuel lines are not square with the bonnets in the fuel injection pump or with the adaptors in the valve cover bases, gently bend the lines

Have questions with 101609-3501?

Group cross 101609-3501 ZEXEL

Komatsu

101609-3501

9 400 615 908

3863866

INJECTION-PUMP ASSEMBLY

S6D102E

S6D102E

101609-3501

9 400 615 908

6735711411

INJECTION-PUMP ASSEMBLY

S6D102E

S6D102E