Information injection-pump assembly

BOSCH

F 01G 09U 068

f01g09u068

ZEXEL

101608-9930

1016089930

NISSAN-DIESEL

16713Z6914

16713z6914

Rating:

Include in #2:

105866-7111

as _

Cross reference number

BOSCH

F 01G 09U 068

f01g09u068

ZEXEL

101608-9930

1016089930

NISSAN-DIESEL

16713Z6914

16713z6914

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8310

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2240

Opening pressure

MPa

18

Opening pressure

kgf/cm2

184

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-4120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.5

3.45

3.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

48.3

46.3

50.3

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.5+-0.5

Pump speed

r/min

330

330

330

Average injection quantity

mm3/st.

9

8

10

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.9)

Pump speed

r/min

1350

1350

1350

Average injection quantity

mm3/st.

60

59

61

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-1.9

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

48.3

44.3

52.3

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

150

150

160

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

-

Advance angle

deg.

1.5

1

2

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

6

5.7

6.3

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

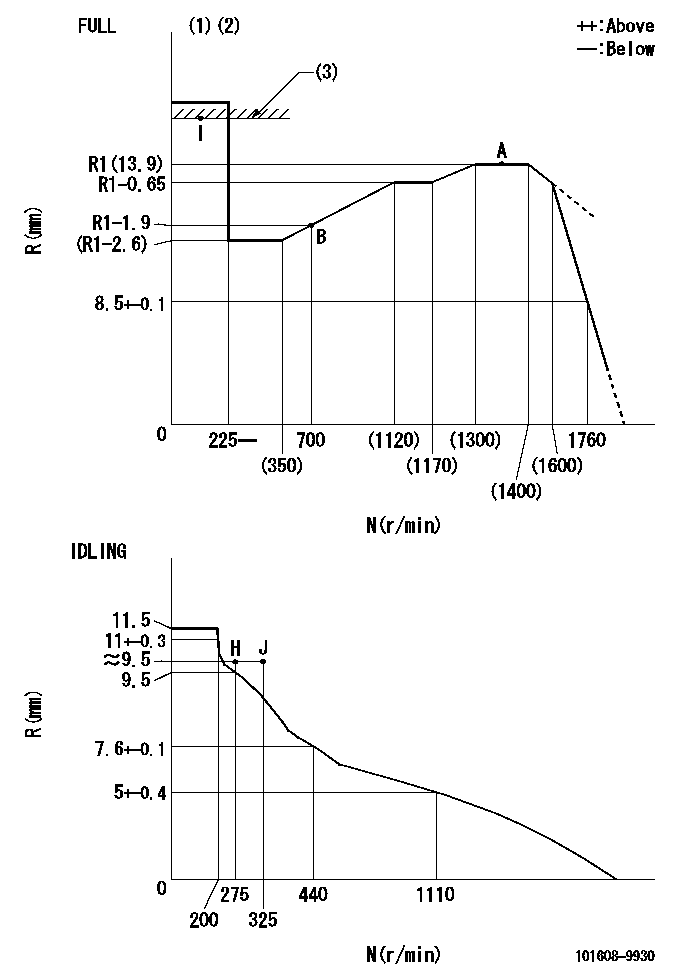

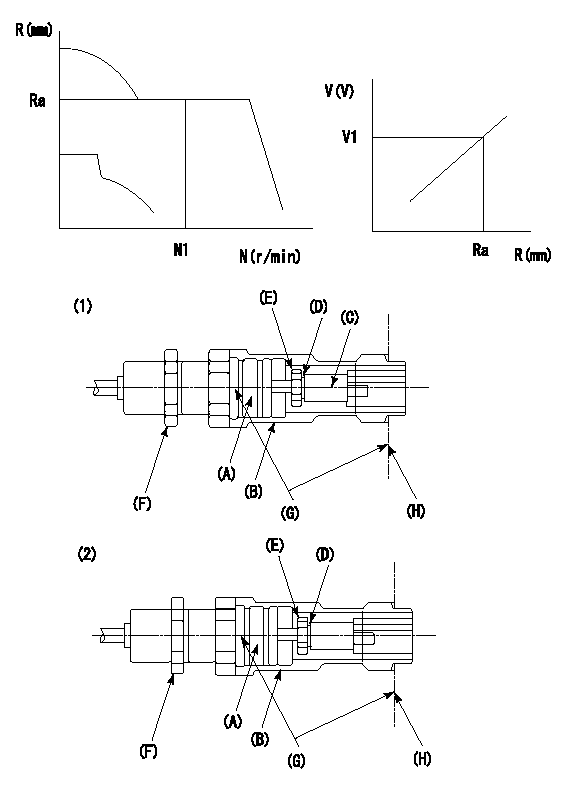

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=N25

----------

----------

T1=N25

----------

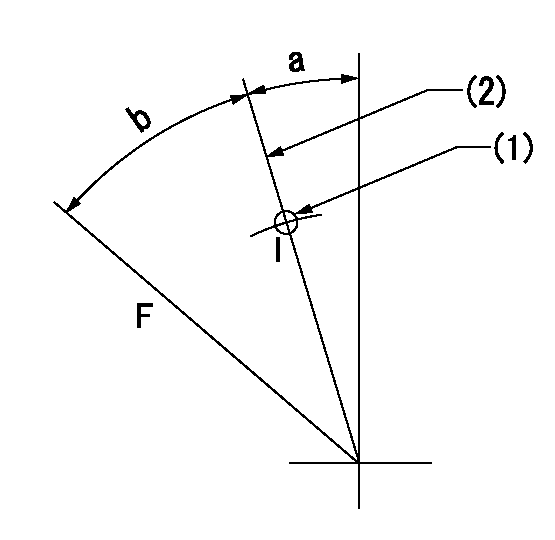

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=38mm

----------

a=5deg+-5deg b=41deg+-3deg

----------

aa=38mm

----------

a=5deg+-5deg b=41deg+-3deg

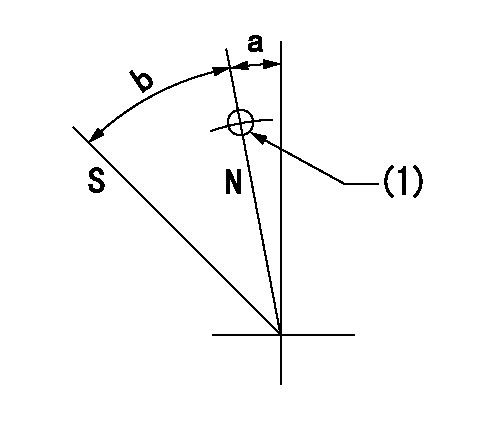

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=42mm

----------

a=5deg+-5deg b=40deg+-5deg

----------

aa=42mm

----------

a=5deg+-5deg b=40deg+-5deg

0000001501 RACK SENSOR

G:Red paint

H:Pump end face

P/N: part number of suitable shim

(1)Threaded type rack block

(2)Welded type rack block

Rack sensor adjustment

1. Threaded type rack sensor (-5*20, P type, no TICS rack limit).

(1)Screw in the bobbin (A) until it contacts the joint (B).

(2)Fix the pump lever.

(3)At speed N1 and rack position Ra, adjust the amount that the bobbin is screwed in so that the amp's output voltage is V1.

(4)Fix using the nut (F).

(5)Affix the caution plate to the upper part of the joint (B).

(6)Apply (G) at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the end surface of the pump (H) and the joint (B)

2. Range for screw-in adjustment between the bobbin (A) and the joint (B) is 9 threads.

Screw in to the end from (the position where the bobbin (A) is rotated 9 turns).

Speed N1, rack position Ra, output voltage V1, rack sensor supply voltage 5+-0.01 (V)

----------

Ra=R1(13.9)mm N1=1350r/min V1=3+-0.01V

----------

----------

Ra=R1(13.9)mm N1=1350r/min V1=3+-0.01V

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

AUGUST 2011

INFORMATION RELEASE MEMO

Reman

PELJ1306 ?2011 Caterpillar REMAN DIESEL PARTICULATE FILTERS FOR MACHINE APPLICATIONS

To provide our customers with cost effective service options to support their Tier 4 emissions engines, Cat Reman has released a Reman version of the diesel particulate filters (DPF) used on many Tier 4 Cat? machines. The DPF traps both soot and ash. Soot is removed through a regeneration process outlined in the machines operation and maintenance manual. Ash that accumulates from engine oil is removed through a cleaning procedure that requires removal of the DPF from the machine. The cleaning procedure requires the DPF to be removed from the machine. Special Instruction REHS5045 outlines the three approved processes for performing the required Diesel Particulate Filter (DPF) maintenance on Tier 4 products equipped with a DPF.

Replacement of the existing DPF with a new Cat DPF

Replacement of the existing DPF with a remanufactured Cat DPF

Removal of the existing DPF and having the DPF cleaned by a Cat approved cleaning device.

The Reman DPFs listed below are available to support these maintenance requirements:

Core Acceptance

After gaining some experience with the previously released DPFs used for on-highway engines and to support the launch of these additional machine DPFs, we have changed some of the inspection criteria and issued a revision to SELD0292. SELD0292-02 Caterpillar Diesel Particulate Filter (DPF) is the current Core Acceptance Criteria (CAC). It is critical to avoid non-operational damage that can decrease the value of the cores. Encourage service technicians to handle and package the cores with care so they will be more likely to be eligible for the full core refunds. Please always refer to the most current version at catreman.cat.com/core to view the latest requirements. The acceptability inspection for these is a simple visual inspection based on the following guidelines:

Warranty

All Reman products carry the same warranty as new parts. Please consult the appropriate warranty statement for your area.

Core Management

Please refer to the Cat Core Management Information System (CMIS 2) related to the parts information application that describes all Reman part/Core Acceptability Family (CAF) and other related information. Also refer to other CMIS 2 inquiry applications such as: Dealer Customer Profile, Inspection Reason Codes, Inspection Line Inquiry, Dealer Add Charges, Dealer Entitlement Activity, Dealer CCR Inquiry, Dealer CCR Entry, Dealer Shipment Processing, Dealer Process Packaging Grief and Reporting. This information is available to all dealers worldwide that have been converted to CMIS 2.

Please go to the Reman web site https://catreman.cat.com for the latest policy and procedural updates that are available to all dealers worldwide explaining policy and procedural information such as Policy and Core Management SELD0122 -10, "Core Management Systems and Operations Procedures SELD0040-14, "Reman Core Return Packaging Instructions And Guidelines SELD0300-00 and "Shipping Instructions" SELD0039-14.

If you have any questions regarding Reman Core Management or Core Management Systems (CMIS2),