Information injection-pump assembly

ZEXEL

101608-9550

1016089550

NISSAN-DIESEL

16713Z6808

16713z6808

Rating:

Cross reference number

ZEXEL

101608-9550

1016089550

NISSAN-DIESEL

16713Z6808

16713z6808

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8260

Bosch type code

9 430 610 133

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

18

Opening pressure

kgf/cm2

184

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131425-0420

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.7

3.65

3.75

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.6

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

90

88.4

91.6

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.5+-0.5

Pump speed

r/min

265

265

265

Average injection quantity

mm3/st.

9

7.2

10.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.6)

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

90

89

91

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.9

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

95

91

99

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

(R1-0.25

)

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

86.5

82.5

90.5

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

120

120

130

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

(900)

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1080

Advance angle

deg.

2

1.5

2.5

Timer adjustment_03

Pump speed

r/min

1225

Advance angle

deg.

2

1.5

2.5

Timer adjustment_04

Pump speed

r/min

1425

Advance angle

deg.

6

5.5

6.5

Remarks

Finish

Finish

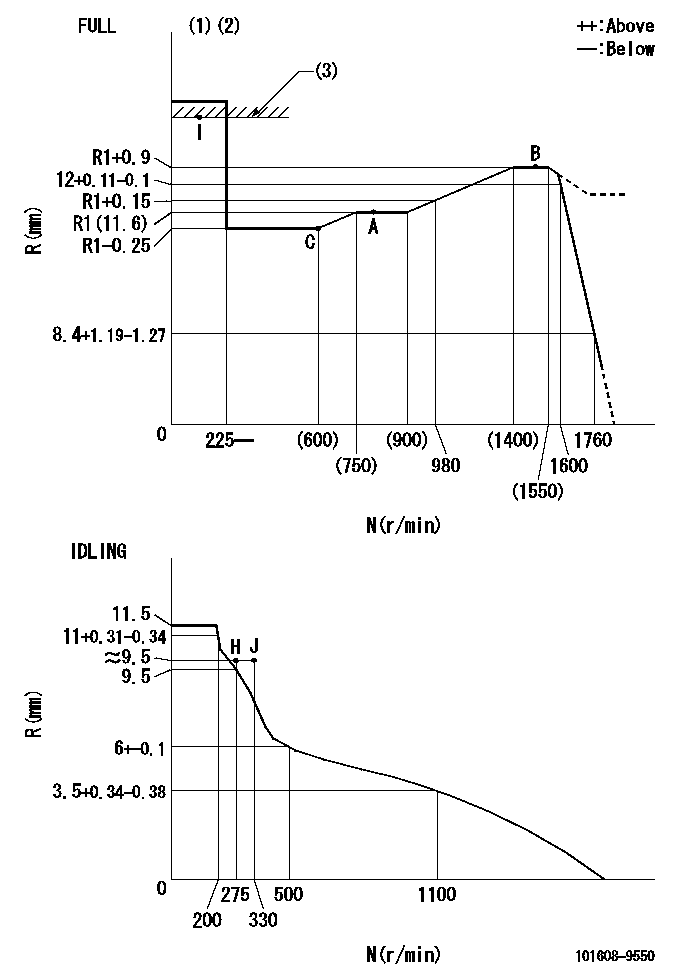

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=M44

----------

----------

T1=M44

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=39mm

----------

a=20deg+-5deg b=42deg+-3deg

----------

aa=39mm

----------

a=20deg+-5deg b=42deg+-3deg

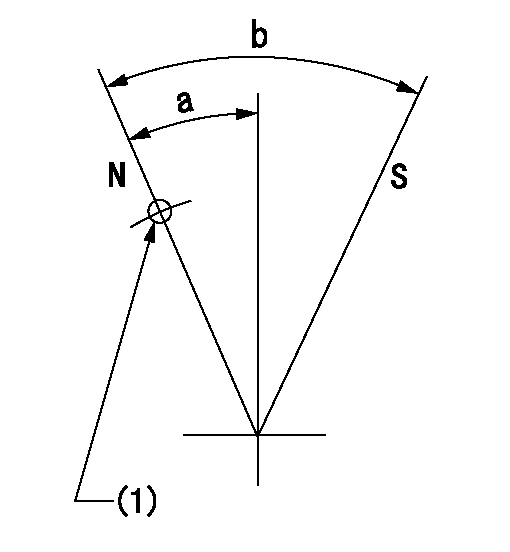

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=42mm

----------

a=25deg+-5deg b=40deg+-5deg

----------

aa=42mm

----------

a=25deg+-5deg b=40deg+-5deg

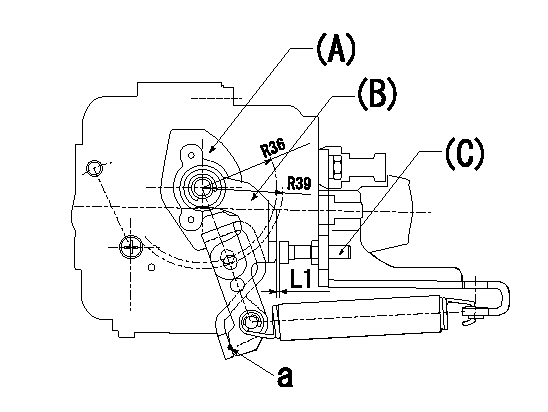

0000001501 LEVER

(a) Speed lever

(B) Accelerator lever

(C) Accelerator lever stopper bolt

1. Accelerator lever setting method

With the speed lever in the idling position, back off the accelerator lever stopper bolt L1 from where it contacts point a. (Back off 1+0.5 turns and set.)

----------

L1=1+0.5mm

----------

----------

L1=1+0.5mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Flywheel

Installation of Flywheel Housing

Installation of flywheel housing(1) Install the oil seal to the flywheel housing.(2) Coat the contact surfaces of the crankcase and flywheel with ThreeBond 1104.(3) Align the holes in the flywheel housing and gasket with the dowel pins on the crankcase, and install them to the crankcase.Installation of Flywheel

(1) Install the flywheel to the crankshaft by aligning the hole with the dowel pin on the back-end of the crankshaft.(2) Place the washer and tighten the four bolts to the specified torque.

Installation of flywheelMeasurement of Flywheel Runout

Measure the flywheel runout with the flywheel installed to the crankshaft. If the standard value is exceeded, check the bolts for tightening condition and the mounting face for adhesion of foreign particles.

Measurement of face runout and circular runoutCylinder Head and Valve Mechanisms

Installation of Valve Stem Seal

(1) Apply engine oil to the valve stem, and insert it into the valve guide.(2) Place a new stem seal on the valve guide.(3) Using the stem seal installer, install the stem seal to the valve guide, making use of the valve stem as a guide.

Installation of valve stem sealInstallation of Valves and Valve Springs

(1) Place the valve spring and retainer on the valve guide, and install the valve cotter using the valve spring pusher.

Excessive compression of the valve spring can cause the retainer to contact the stem seal and damage the seal.

Installation of valve and valve spring(2) Using a soft-faced hammer, tap the top of the valve stem several times to make sure that the spring and valve cotter are securely installed.

Confirmation of secure valve cotter installationInstallation of Cylinder Head Gasket

(1) Make sure that the top face of the crankcase and piston upper surfaces are clean and free of dust.(2) Place a new gasket of the crankcase, making sure that the dowel pins on the top face of the crankcase enter the holes in the gasket.

Do not use a liquid gasket.

Installation of cylinder head gasketInstallation of Cylinder Head

Place the cylinder head on the head gasket, making sure that the dowel pins on the top face of the crankcase enters the holes in the cylinder head.

Installation of cylinder head assemblyTightening of Cylinder Head Bolts

Tighten the cylinder head bolts, following the tightening sequence shown in the diagram two or three times before reaching the specified torque.

Cylinder head bolt tightening sequenceAssembly of Rocker Arm and Rocker Shaft Assembly

When installing the rocker arms, make sure that the shaft assembly marks face the front of the engine, as shown in the diagram. After the assembly, make sure that the rocker arms move smoothly.

Assembly of rocker shaft assemblyInstallation of Pushrods

(1) Insert the pushrods in the cylinder head through the pushrod holes.(2) Make sure that the ball end of each pushrod rests securely on the curved surface of the tappet.Installation of Rocker Shaft Assemblies

(1) Install the valve caps.(2) When installing the rocker shaft brackets, tighten the long bolts first, then tighten the short bolts (reversal of removal sequence).

Installation of rocker shaft assemblyAdjustment of Valve Clearances

(1) Confirming the top dead center on the

Installation of Flywheel Housing

Installation of flywheel housing(1) Install the oil seal to the flywheel housing.(2) Coat the contact surfaces of the crankcase and flywheel with ThreeBond 1104.(3) Align the holes in the flywheel housing and gasket with the dowel pins on the crankcase, and install them to the crankcase.Installation of Flywheel

(1) Install the flywheel to the crankshaft by aligning the hole with the dowel pin on the back-end of the crankshaft.(2) Place the washer and tighten the four bolts to the specified torque.

Installation of flywheelMeasurement of Flywheel Runout

Measure the flywheel runout with the flywheel installed to the crankshaft. If the standard value is exceeded, check the bolts for tightening condition and the mounting face for adhesion of foreign particles.

Measurement of face runout and circular runoutCylinder Head and Valve Mechanisms

Installation of Valve Stem Seal

(1) Apply engine oil to the valve stem, and insert it into the valve guide.(2) Place a new stem seal on the valve guide.(3) Using the stem seal installer, install the stem seal to the valve guide, making use of the valve stem as a guide.

Installation of valve stem sealInstallation of Valves and Valve Springs

(1) Place the valve spring and retainer on the valve guide, and install the valve cotter using the valve spring pusher.

Excessive compression of the valve spring can cause the retainer to contact the stem seal and damage the seal.

Installation of valve and valve spring(2) Using a soft-faced hammer, tap the top of the valve stem several times to make sure that the spring and valve cotter are securely installed.

Confirmation of secure valve cotter installationInstallation of Cylinder Head Gasket

(1) Make sure that the top face of the crankcase and piston upper surfaces are clean and free of dust.(2) Place a new gasket of the crankcase, making sure that the dowel pins on the top face of the crankcase enter the holes in the gasket.

Do not use a liquid gasket.

Installation of cylinder head gasketInstallation of Cylinder Head

Place the cylinder head on the head gasket, making sure that the dowel pins on the top face of the crankcase enters the holes in the cylinder head.

Installation of cylinder head assemblyTightening of Cylinder Head Bolts

Tighten the cylinder head bolts, following the tightening sequence shown in the diagram two or three times before reaching the specified torque.

Cylinder head bolt tightening sequenceAssembly of Rocker Arm and Rocker Shaft Assembly

When installing the rocker arms, make sure that the shaft assembly marks face the front of the engine, as shown in the diagram. After the assembly, make sure that the rocker arms move smoothly.

Assembly of rocker shaft assemblyInstallation of Pushrods

(1) Insert the pushrods in the cylinder head through the pushrod holes.(2) Make sure that the ball end of each pushrod rests securely on the curved surface of the tappet.Installation of Rocker Shaft Assemblies

(1) Install the valve caps.(2) When installing the rocker shaft brackets, tighten the long bolts first, then tighten the short bolts (reversal of removal sequence).

Installation of rocker shaft assemblyAdjustment of Valve Clearances

(1) Confirming the top dead center on the