Information injection-pump assembly

ZEXEL

101608-9390

1016089390

NISSAN-DIESEL

16713Z6715

16713z6715

Rating:

Cross reference number

ZEXEL

101608-9390

1016089390

NISSAN-DIESEL

16713Z6715

16713z6715

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-1520

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.8

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

70.5

68.9

72.1

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

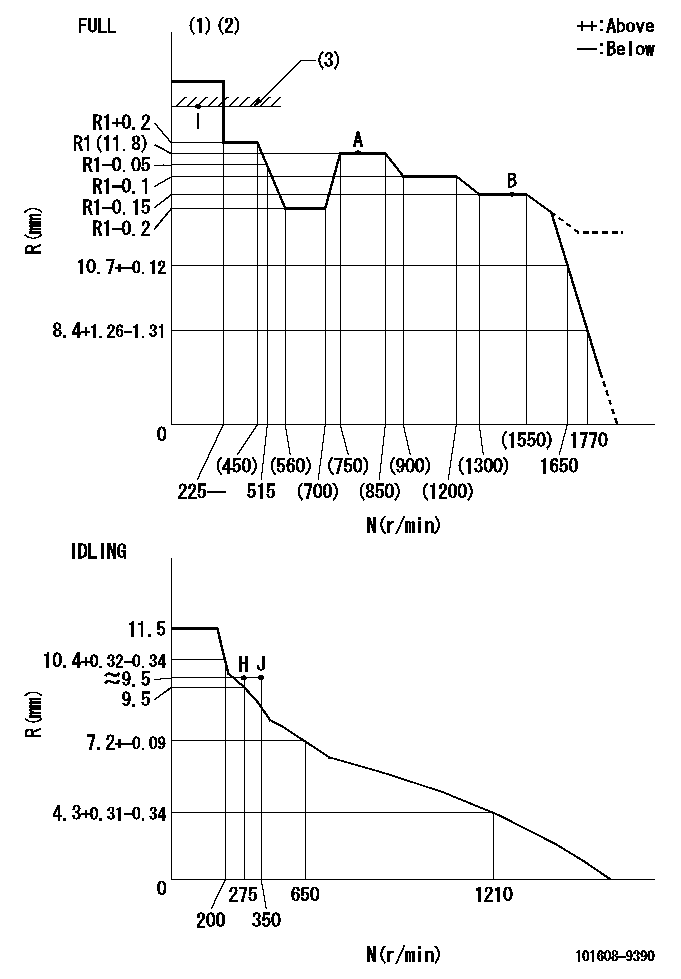

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

10

8.2

11.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.8)

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

70.5

69.5

71.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.15

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

77

73

81

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

80

90

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1200--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1150

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

6.5

6.2

6.8

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=M35

----------

----------

T1=M35

----------

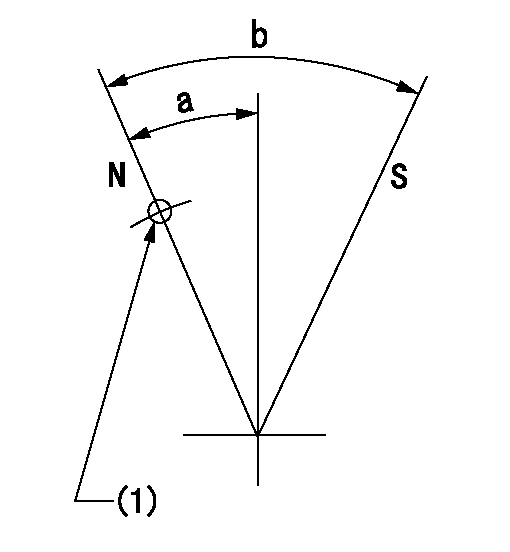

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=36mm

----------

a=25deg+-5deg b=37deg+-3deg

----------

aa=36mm

----------

a=25deg+-5deg b=37deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=42mm

----------

a=25deg+-5deg b=40deg+-5deg

----------

aa=42mm

----------

a=25deg+-5deg b=40deg+-5deg

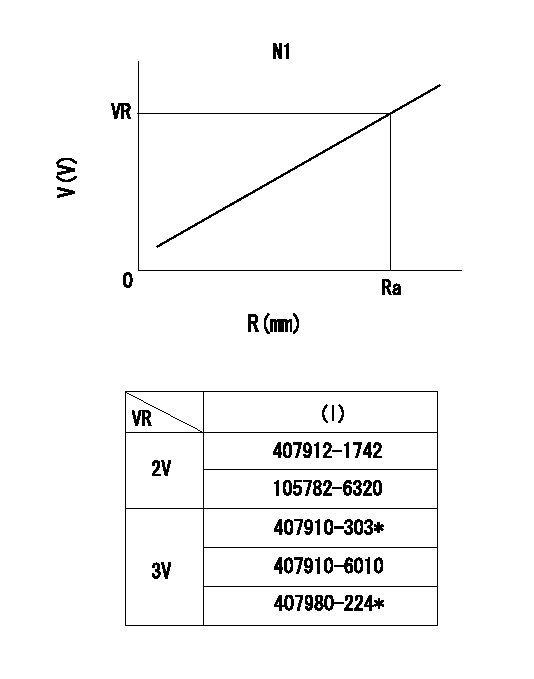

0000001501 RACK SENSOR

R:Rack position (mm)

V:Voltage (V)

After installing the rack sensor, confirm the output value (VR).

----------

N1=800r/min Ra=R1(11.8)mm VR=2.5+-0.01V

----------

----------

N1=800r/min Ra=R1(11.8)mm VR=2.5+-0.01V

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

This Program must be administered as soon as possible. When reporting the repair, use "PI3841" as the Part Number, "7751" as the Group Number, "56" as the Warranty Claim Description Code and "T" as the SIMS Description Code. Exception: If the repair is done after failure, use "PI3841" as the Part Number, "7751" as the Group Number, "96" as the Warranty Claim Description Code, and "Z" as the SIMS Description Code.

Completion Date

July 31, 1996Termination Date

January 31, 1997Problem

Shot peening on some 3500 Diesel Cylinder Heads extends too far into the injector bore. This may cause the top injector o-ring to be cut or torn on installation.

Affected Product

Model & Identification Number

777C (4XJ844, 4XJ846-872, 4XJ879, 4XJ883, 4XJ885)

785B (6HK483-489)

789B (7EK355-364, 7EK367)

793B (1HL359-367)

3512 (1LM67-73 4WJ649 )

3512B (8RM126-129 4TN40 )

3516 (4XF605, 4XF606 5SJ392-397 2PK918 )

3516B (8CN134 8KN69 , 8KN70 7RN253-259 )

Parts Needed

Dealers will need to order parts for this Program.

1 - 8J8725 Seal-O-Ring (per cylinder)1 - 8T7767 Wheel-Level (per engine)1 - 8T7768 Mandrel (per engine)Action Required

1. Remove the valve cover, rocker arm assembly and fuel injector.2. Inspect the top injector o-ring seal for damage. If damaged, polish the upper injector bore area using an 8T7767 Polishing Wheel and an 8T7768 Mandrel. Install a new 8J8725 O-Ring Seal on each injector.3. Install the injector using clean engine oil in the injector bore and on the o-rings.4. Install rocker arm assembly and reset valves and injector. Install valve covers.Owner Notification

U.S. and Canadian owners will receive the attached Owner Notification.

Service Claim Allowances

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

Attach.(1-Owner Notification)Copy Of Owner Notification For U.s. And Canadian Owners

This Program must be administered as soon as possible. When reporting the repair, use "PI3841" as the Part Number, "7751" as the Group Number, "56" as the Warranty Claim Description Code and "T" as the SIMS Description Code. Exception: If the repair is done after failure, use "PI3841" as the Part Number, "7751" as the Group Number, "96" as the Warranty Claim Description Code, and "Z" as the SIMS Description Code.

Completion Date

July 31, 1996Termination Date

January 31, 1997Problem

Shot peening on some 3500 Diesel Cylinder Heads extends too far into the injector bore. This may cause the top injector o-ring to be cut or torn on installation.

Affected Product

Model & Identification Number

777C (4XJ844, 4XJ846-872, 4XJ879, 4XJ883, 4XJ885)

785B (6HK483-489)

789B (7EK355-364, 7EK367)

793B (1HL359-367)

3512 (1LM67-73 4WJ649 )

3512B (8RM126-129 4TN40 )

3516 (4XF605, 4XF606 5SJ392-397 2PK918 )

3516B (8CN134 8KN69 , 8KN70 7RN253-259 )

Parts Needed

Dealers will need to order parts for this Program.

1 - 8J8725 Seal-O-Ring (per cylinder)1 - 8T7767 Wheel-Level (per engine)1 - 8T7768 Mandrel (per engine)Action Required

1. Remove the valve cover, rocker arm assembly and fuel injector.2. Inspect the top injector o-ring seal for damage. If damaged, polish the upper injector bore area using an 8T7767 Polishing Wheel and an 8T7768 Mandrel. Install a new 8J8725 O-Ring Seal on each injector.3. Install the injector using clean engine oil in the injector bore and on the o-rings.4. Install rocker arm assembly and reset valves and injector. Install valve covers.Owner Notification

U.S. and Canadian owners will receive the attached Owner Notification.

Service Claim Allowances

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

Attach.(1-Owner Notification)Copy Of Owner Notification For U.s. And Canadian Owners